Jelly sheet and vermicelli and processing method thereof

A processing method and technology of vermicelli, applied in the functions of food ingredients, food ingredients containing natural extracts, food science and other directions, can solve the problems of single nutrition, high processing cost, unreal color, etc., and achieve rich nutrition and soft and glutinous taste. Strong, solve stale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Notice:

[0066] 1. Production and processing environment, the temperature is not lower than 15°C, and the humidity is not lower than 10%;

[0067] 2. There should be no hard particle nodules when adding animal and plant extracts.

[0068] 1. Additives

[0069] The additives include the following components in percentage by weight: 78 parts of sodium alginate, 10 parts of glycerol monostearate, 1 part of potassium chloride, 2 parts of calcium chloride, 2 parts of konjac gum and 3 parts of xanthan gum.

[0070] 2. Take pure potato starch, cuttlefish juice, pumpkin powder, beetroot powder, purple potato powder, spirulina powder, bee pollen, durian powder, butterfly pea pollen as examples to make vermicelli vermicelli with colored texture. The method is as follows:

[0071] First make 6 kinds of dough

[0072] (1) Production of white pure potato dough:

[0073] Step 1, earlier with 500 gram potato starches, additive 0.1% (in total starch amount 600 grams), refined lard...

Embodiment 2

[0150] 1. Additives

[0151] The additives include the following components in percentage by weight: 80 parts of sodium alginate, 13 parts of glyceryl monostearate, 0.5 parts of potassium chloride, 1.5 parts of calcium chloride, 1.5 parts of konjac gum, and 3.5 parts of xanthan gum;

[0152] Starch: potato starch, tapioca starch, pueraria starch and glutinous rice flour are mixed in a ratio of 2:1:1:1 to prepare mixed starch.

[0153] 2. Take gardenia blue pigment, carrot powder, mint powder, and mulberry juice as an example to make colored and textured vermicelli as follows:

[0154] Make 5 kinds of dough first

[0155] (1) White dough production:

[0156] Step 1, first 500 grams of starch, 0.4% of additives (in 600 grams of total starch), 5% of refined lard (in 600 grams of total starch), and 0.5% of emulsified oil (in 600 grams of total starch) , 0.8% of salt (based on 600 grams of total starch content) is poured into a container and mixed evenly for later use.

[0157]...

experiment example 1

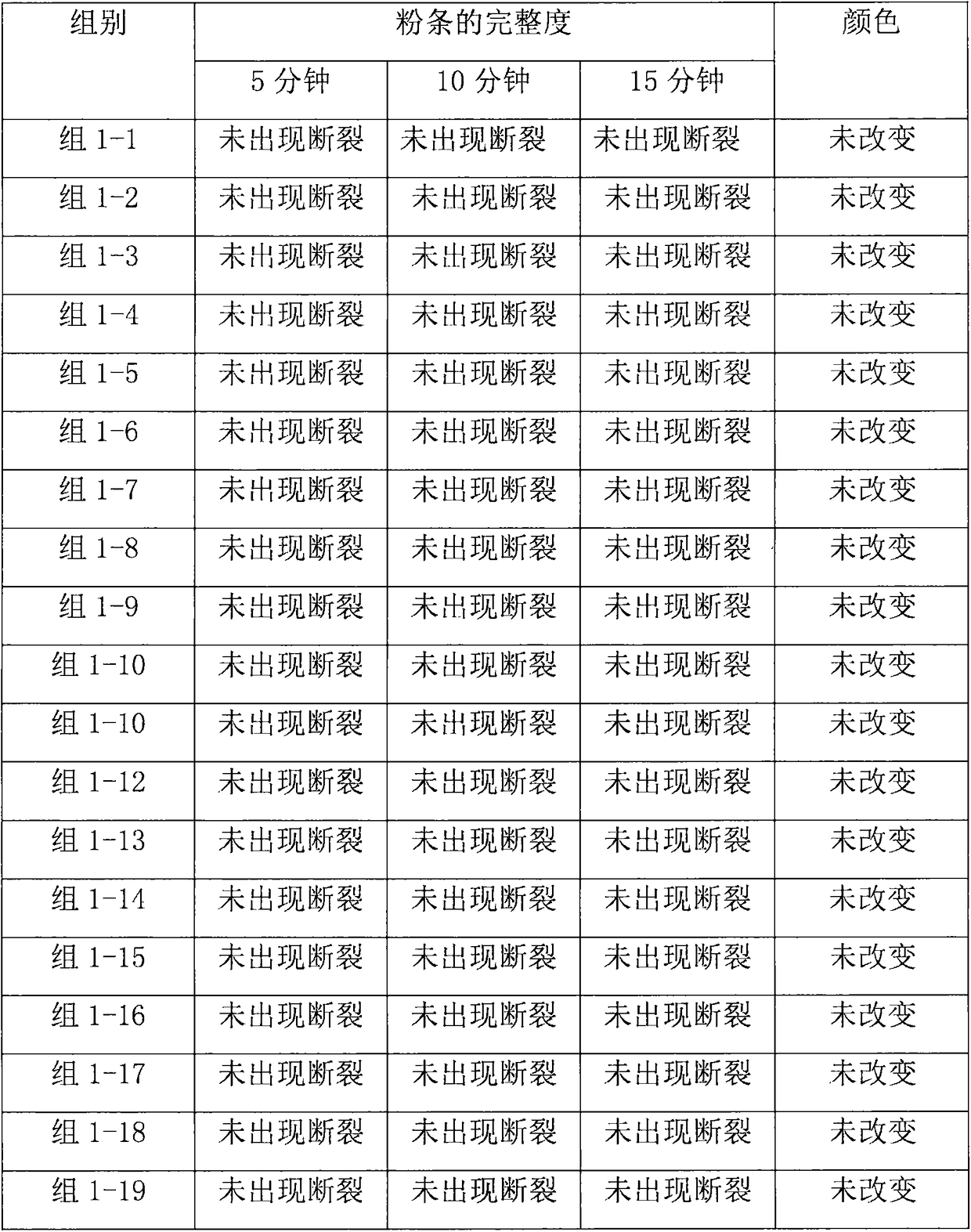

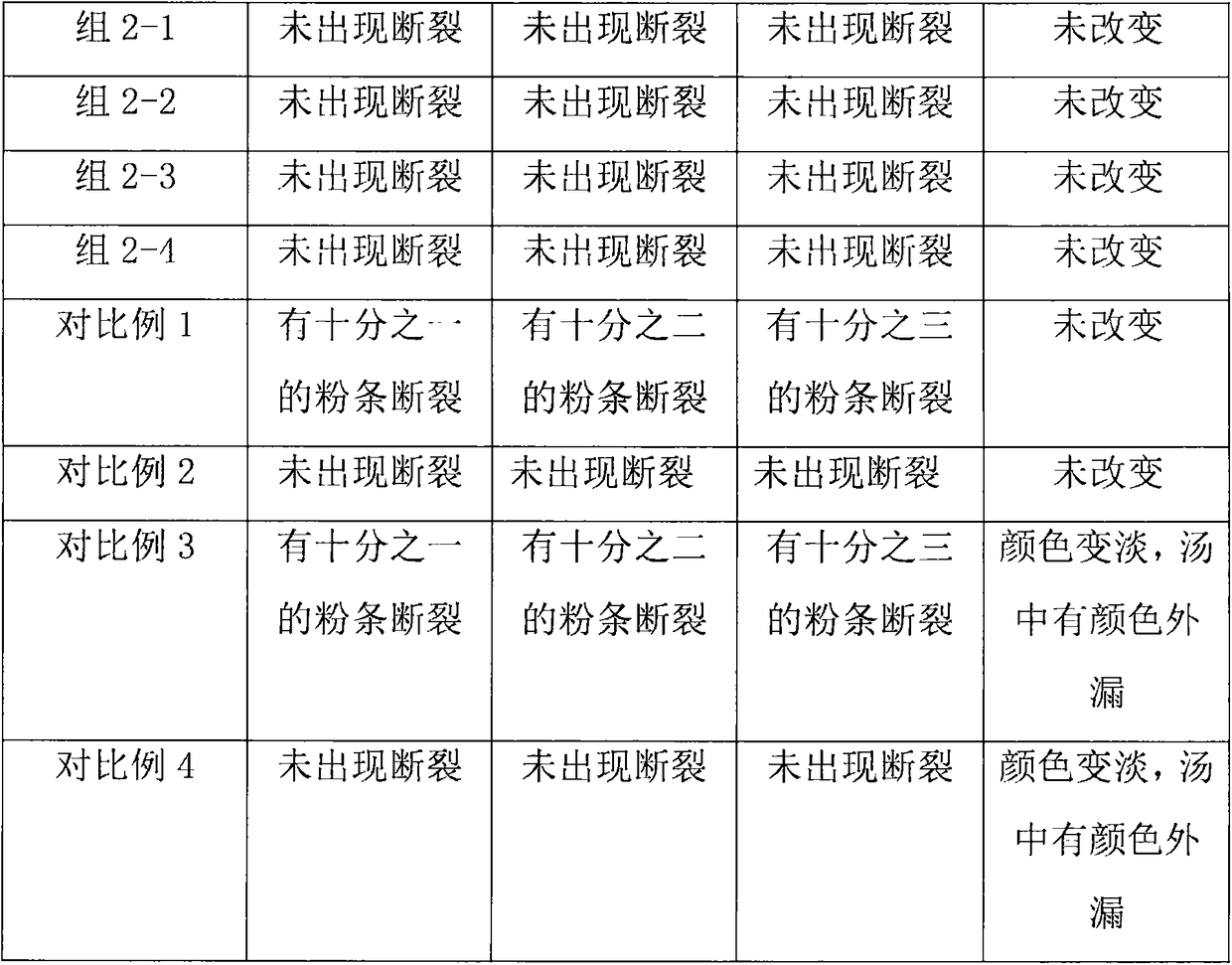

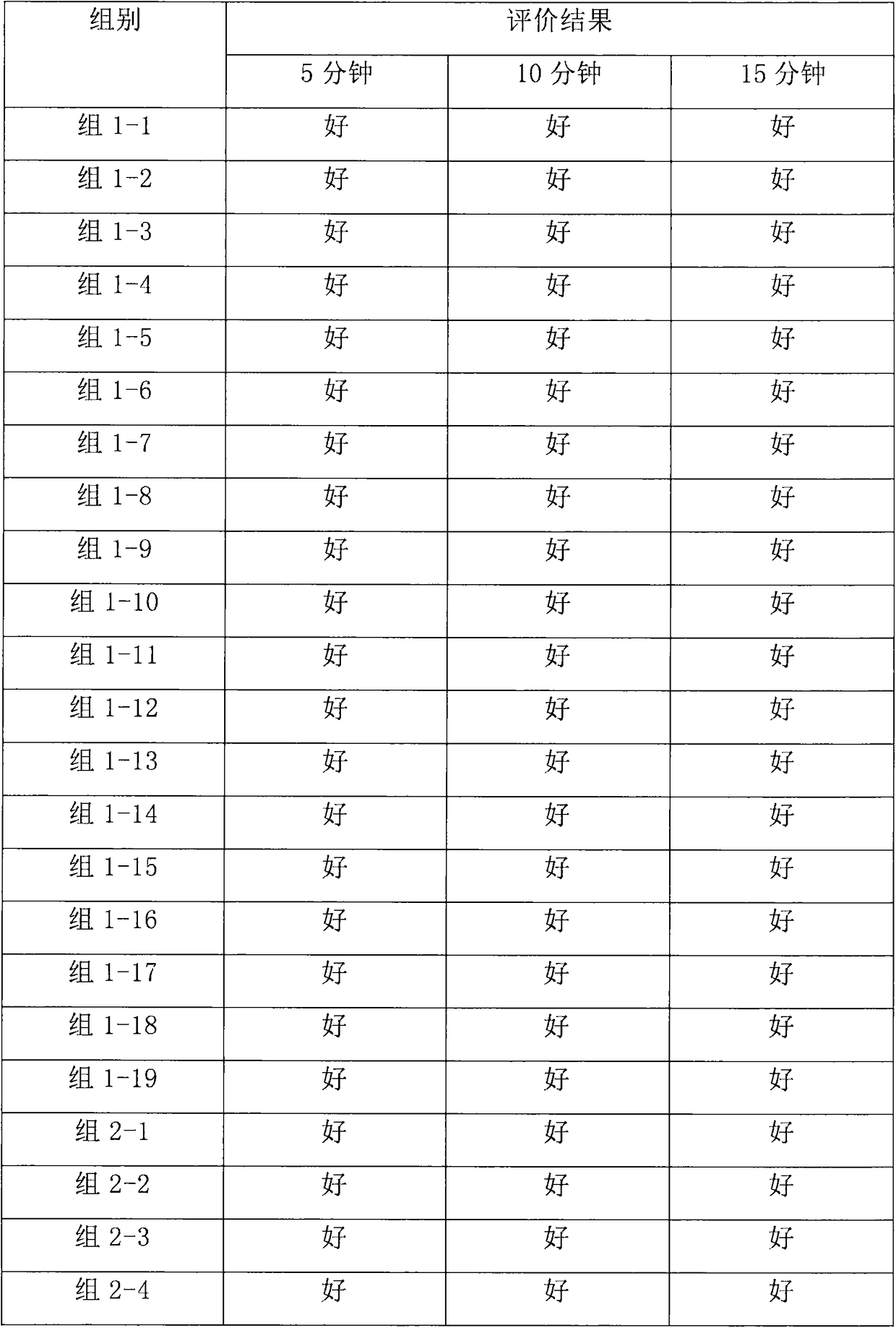

[0193] The vermicelli made in Examples 1-2 and Comparative Example were put into boiling water and boiled for 5 minutes, 10 minutes and 15 minutes respectively, and then pulled out to observe the integrity and color of the vermicelli. The results are shown in Table 1.

[0194] The comparison result of the potato flour that each embodiment of table 1 and comparative example make

[0195]

[0196]

[0197] It can be seen from the comparison results of each embodiment and Comparative Example 1 that the vermicelli obtained by the preparation method provided by the present invention is not only more novel in structure, but also less likely to break and more resistant to cooking. And the color change is not obvious, and the original color is still maintained, while the colors mixed in the comparison ratio are easy to react with each other, making the color leak out, contaminating the container, and the experience is poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com