Application of waste hydrofluoric acid etching solution to accelerating agent synthesis

A technology of hydrofluoric acid and etching solution, which is applied in the application field of waste hydrofluoric acid etching solution in the synthesis of accelerators, can solve the problem of increasing the investment in operating costs of enterprises, the inability to completely remove hydrofluoric acid, and the high energy consumption of processing. and other problems, to achieve the effect of reducing operating costs, strong complexing ability, and short coagulation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

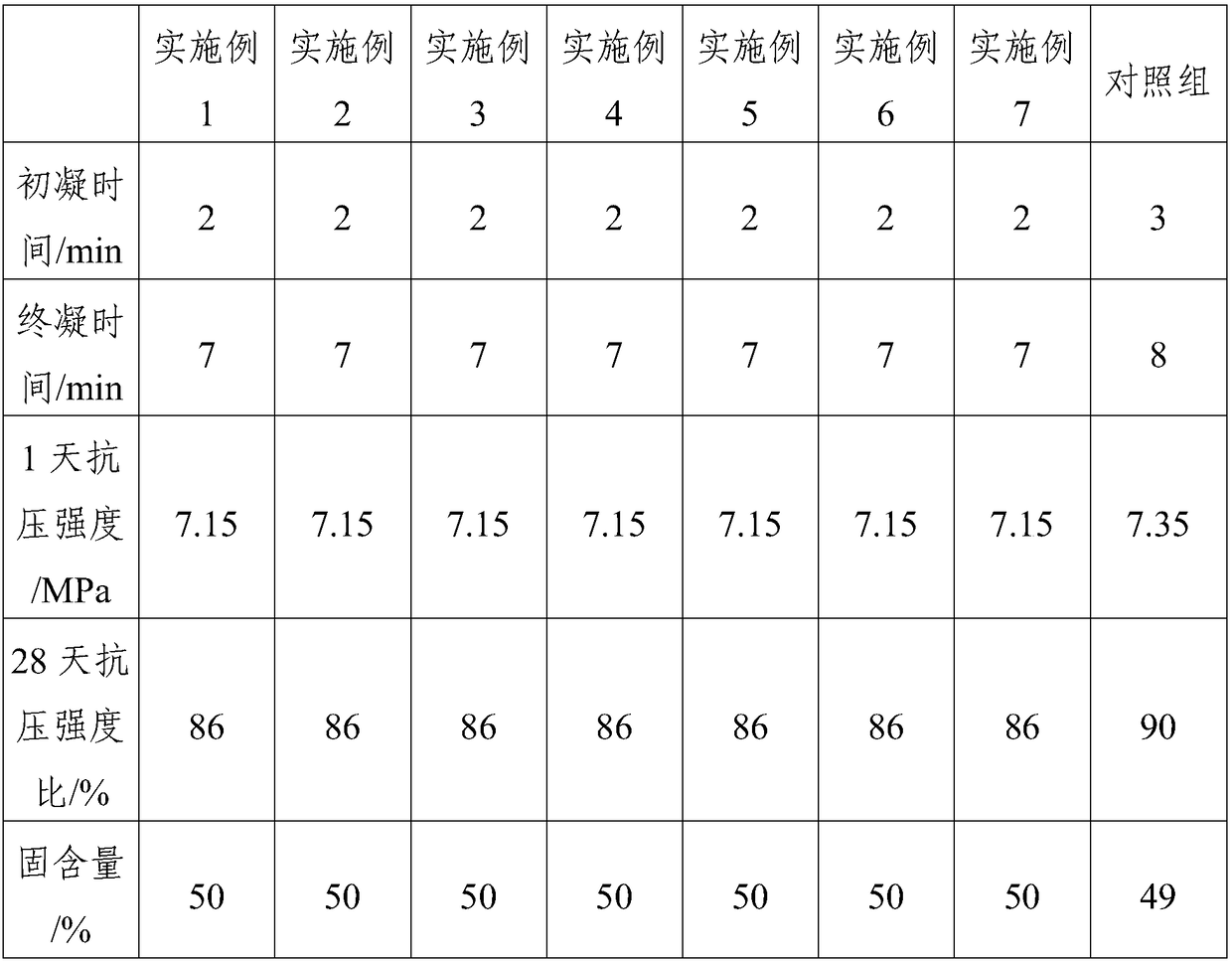

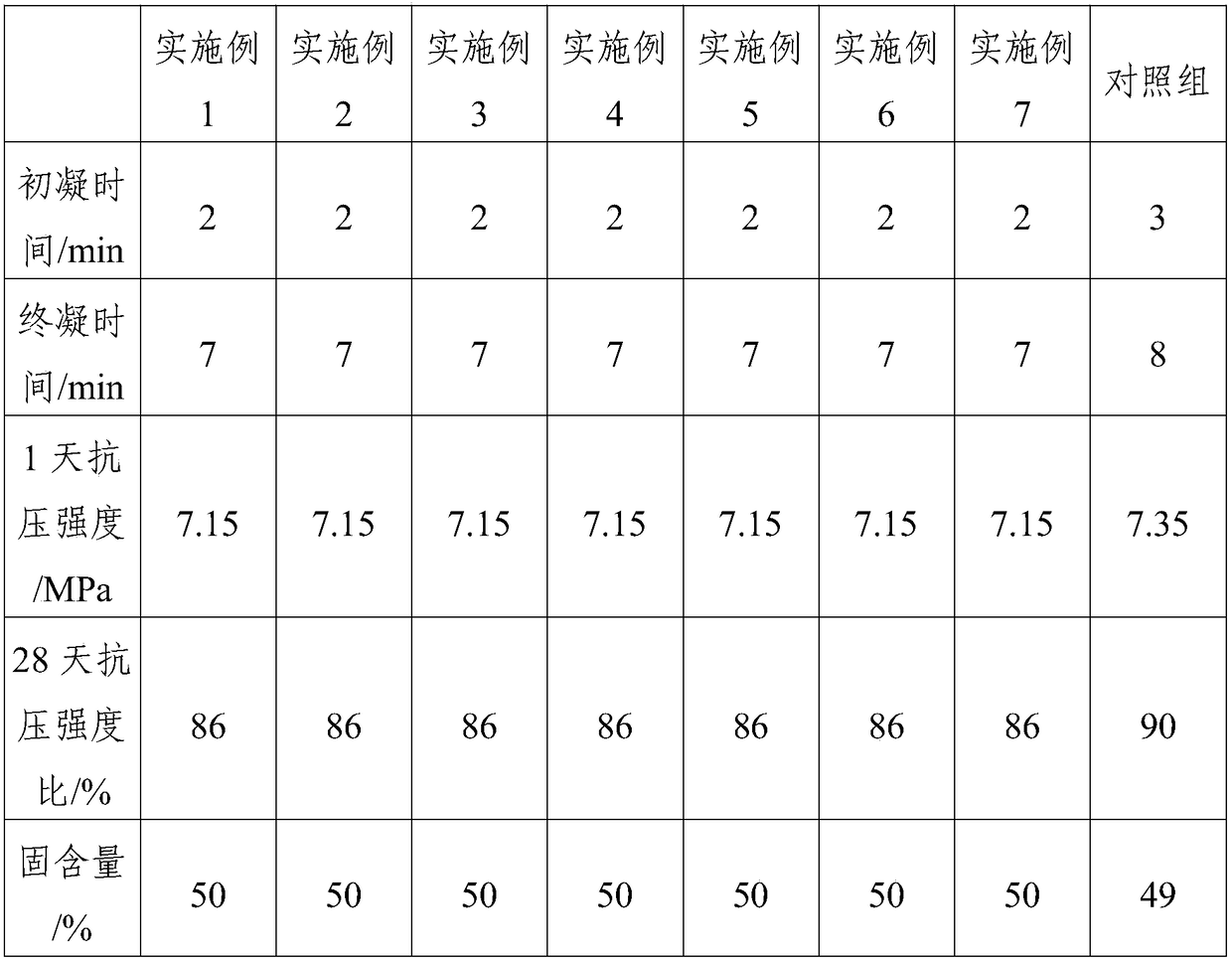

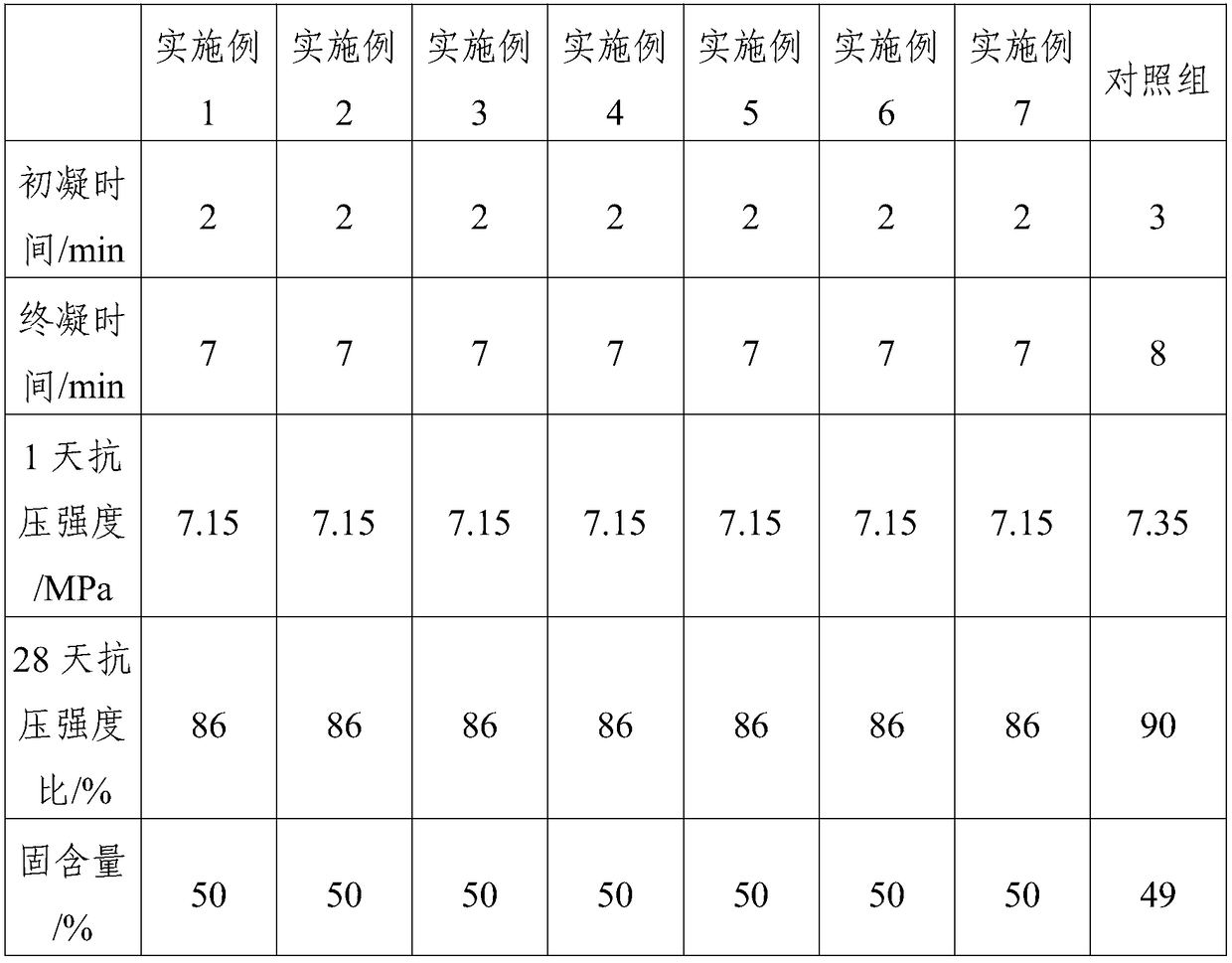

Examples

Embodiment 1

[0020] The invention provides a kind of technology that utilizes waste hydrofluoric acid etchant to prepare quick-setting agent, and its technology comprises the following steps:

[0021] (1) Add 100 parts of deionized water to the four-necked flask, and use an alcohol lamp to heat the four-necked flask;

[0022] (2) When the temperature of the deionized water in the four-necked flask reaches 40°C, add 50 parts of aluminum hydroxide to the four-necked flask, stir evenly, then add 20 parts of waste hydrofluoric acid etching solution to the four-necked flask, and continue Heating, keeping the temperature at 85°C for 1h;

[0023] (3) Add 10 parts of boric acid and 10 parts of phosphoric acid successively to the mixed solution after the reaction in step (2), keep the temperature at 90° C., and the time is 0.5 h;

[0024] (4) Add 100 parts of deionized water and 300 parts of aluminum sulfate hydrate successively to the mixed solution after the reaction in step (3), keeping the tem...

Embodiment 2

[0027] The invention provides a kind of technology that utilizes waste hydrofluoric acid etchant to prepare quick-setting agent, and its technology comprises the following steps:

[0028] (1) Add 175 parts of deionized water to the four-necked flask, and use an alcohol lamp to heat the four-necked flask;

[0029] (2) When the temperature of the deionized water in the four-necked flask reaches 40°C, add 100 parts of aluminum hydroxide to the four-necked flask, stir evenly, then add 80 parts of waste hydrofluoric acid etching solution to the four-necked flask, and continue Heating, keeping the temperature at 85°C for 1h;

[0030] (3) Add 10 parts of boric acid and 10 parts of phosphoric acid successively to the mixed solution after the reaction in step (2), keep the temperature at 90° C., and the time is 0.5 h;

[0031] (4) Add 175 parts of deionized water and 450 parts of aluminum sulfate hydrate successively to the mixed solution after the reaction in step (3), keeping the te...

Embodiment 3

[0034] The invention provides a kind of technology that utilizes waste hydrofluoric acid etchant to prepare quick-setting agent, and its technology comprises the following steps:

[0035] (1) Add 122 parts of deionized water to the four-necked flask, and use an alcohol lamp to heat the four-necked flask;

[0036] (2) When the temperature of the deionized water in the four-necked flask reaches 40°C, add 58 parts of aluminum hydroxide to the four-necked flask, stir evenly, then add 30 parts of waste hydrofluoric acid etching solution to the four-necked flask, and continue Heating, keeping the temperature at 85°C for 1h;

[0037] (3) Add 13 parts of boric acid and 10 parts of phosphoric acid successively to the mixed solution after the reaction in step (2), keep the temperature at 90° C., and the time is 0.5 h;

[0038] (4) Add 122 parts of deionized water and 325 parts of aluminum sulfate hydrate successively to the mixed solution after the reaction in step (3), keeping the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com