E-Fenton oxidation technique of dirty blocking agent in reverse osmosis concentrating liquid

A technology of reverse osmosis concentrate and antiscalant, which is applied in the direction of chemical instruments and methods, reverse osmosis, osmosis/dialysis water/sewage treatment, etc., can solve the problems such as unusable, improve the water recovery rate of the reverse osmosis system, Strong oxidation and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

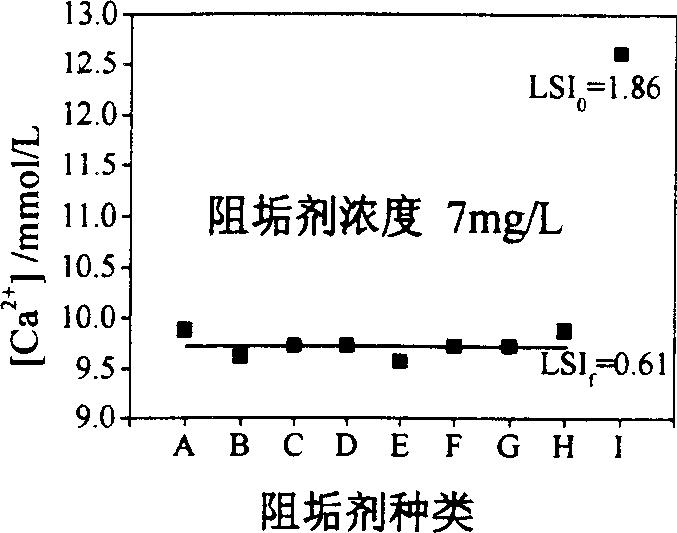

[0018] Weigh out 0.72 g of NaHCO 3 , 1.18 g CaCl 2 , 0.22 g MgSO 4 ·7H 2 O, 0.228 g NaNO 3 , placed in 800 ml of distilled water to prepare a concentrated solution with an initial pH of 7.8 and an initial LSI 0 is 1.86. Add scale inhibitor, and the concentration of scale inhibitor is 7mg / L.

[0019] Electrolytic anode is made of iron plate, cathode is made of porous graphite, and the area of both electrodes is 45cm 2 . The cathode is ventilated by an air pump, and the air flow is 0.12m 3 / h, the electrolysis voltage was 5V, the time was 30 minutes, and the solution was electrolyzed under stirring. After electrolysis, 200 mg / L of aluminum sulfate was added to conduct coagulation filtration to obtain a treated concentrate. During coagulation, coagulation was performed at 300 rpm for half a minute, followed by 5 minutes at 50 rpm.

[0020] Electro-Fenton oxidation was performed on 8 different commercial scale inhibitors. These scale inhibitors are represented by lette...

Embodiment 2

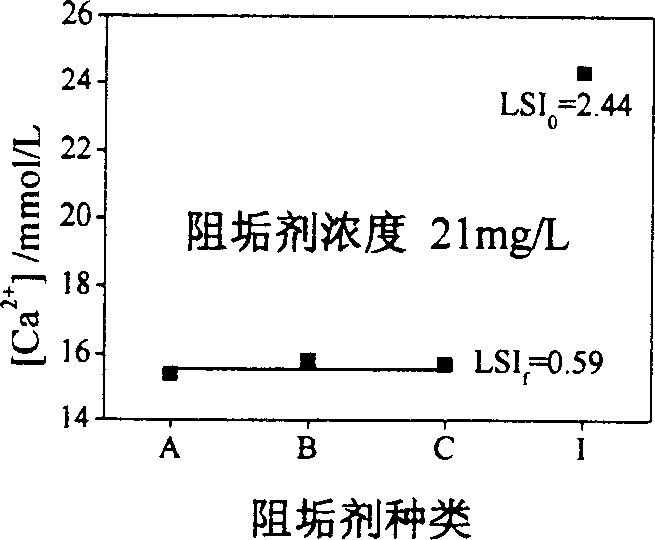

[0023] Weigh out 1.712 g of NaHCO 3 , 2.458 g CaCl 2 , 0.414 g MgSO 4 ·7H 2 O, 0.428 g NaNO 3 , placed in 800 ml of distilled water to prepare a concentrated solution with an initial pH of 7.8 and an initial LSI 0 is 2.44. Three antiscalants A, B and C were added for electrolysis, and their concentrations were all 21 mg / L.

[0024] Electrolytic anode is made of iron plate, cathode is made of porous graphite, and the area of both electrodes is 45cm 2 . The cathode is ventilated by an air pump, and the air flow is 0.12m 3 / h, the electrolysis voltage was 5V, the time was 30 minutes, and the solution was electrolyzed under stirring. After electrolysis, 200 mg / L of aluminum sulfate was added to conduct coagulation filtration to obtain a treated concentrate. During coagulation, coagulation was performed at 300 rpm for half a minute, followed by 5 minutes at 50 rpm.

[0025] The result of electrolysis is figure 2 shown. As can be seen from the figure, the LSI of the c...

Embodiment 3

[0027] Weigh out 0.72 g of NaHCO 3 , 1.18 g CaCl 2 , 0.22 g MgSO 4 ·7H 2 O, 0.228 g NaNO 3 , placed in 800 ml of distilled water to prepare a concentrated solution with an initial pH of 7.8 and an initial LSI 0 is 1.86. Add scale inhibitor B, take 3 concentrations for electrolysis, which are 7, 21 and 35 mg / L respectively.

[0028] Electrolytic anode is made of iron plate, cathode is made of porous graphite, and the area of both electrodes is 45cm 2 . The cathode is ventilated by an air pump, and the air flow is 0.03m 3 / h, the electrolysis voltage was 5V, the time was 30 minutes, and the solution was electrolyzed under stirring. After electrolysis, 200 mg / L of aluminum sulfate was added to conduct coagulation filtration to obtain a treated concentrate. During coagulation, coagulation was performed at 300 rpm for half a minute, followed by 5 minutes at 50 rpm.

[0029] The LSI of the treated concentrate was calculated by ion analysis of the solution f They are red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com