Composite material for building and preparation method thereof

A technology for composite materials and construction, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems that the environmental protection of materials cannot be well taken into account

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

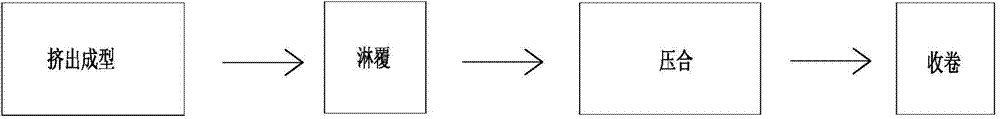

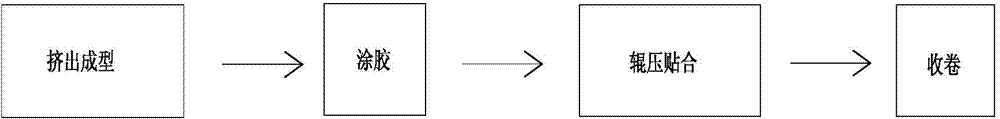

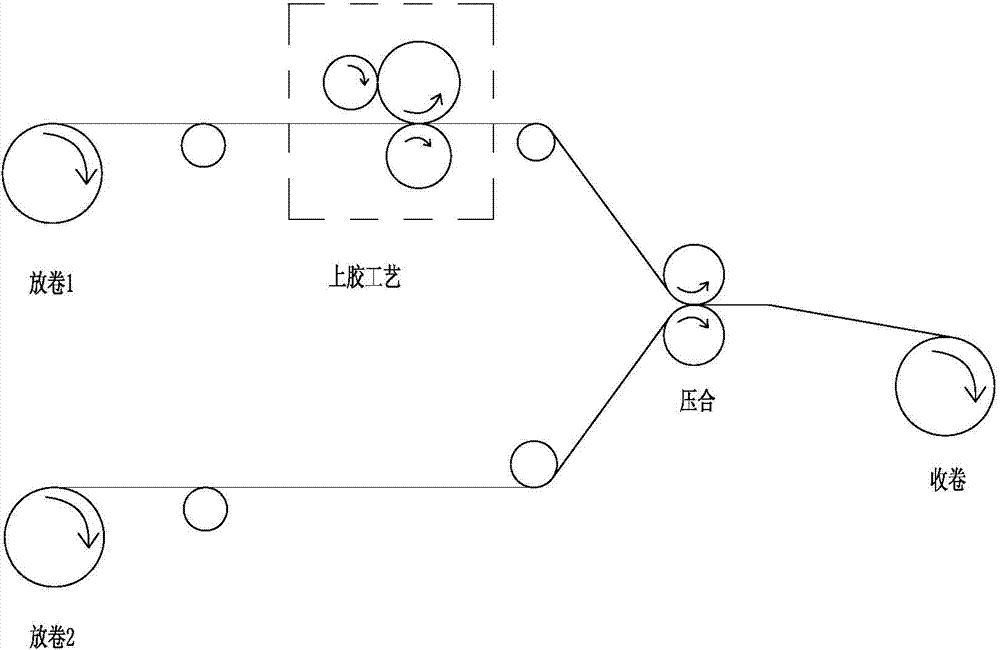

Method used

Image

Examples

Embodiment 1

[0094] Combine 30μm polyether ester thermoplastic resin film with 40g / m 2 The weight of the polyester four-way stretch knitted fabric is bonded to the point-shaped micro-concave board with thermoplastic polyester glue, and the weight of the glue is 6g / m 2 , the production line speed is 30m / min, the pressing temperature is 150°C, and the pressure is 0.1MPa, and the bonded products are cooled and rolled online. Obtain a composite material for construction with long-term waterproof, high and low temperature resistance, weather resistance, ultraviolet (UV) blocking, heat insulation, flame retardant, moisture permeability, moisture resistance, breathability, environmental protection, 100% bacteria blocking, high strength, etc. . Among them, the average value of the peel force GB8808-1988 test results is 3.5N / 15cm. The high and low temperature resistance test is GBT2423.22-2012 standard test for more than 5000 times of thermal shock, the weather resistance test is ASTMD-3105 test e...

Embodiment 2

[0096] Combine 30μm polyether ester thermoplastic resin film with 40g / m 2 Polyolefin PP non-woven fabric, after spraying and laminating with SIS type hot melt adhesive, the glue weight is 2g / m 2 , the production line speed is 100m / min, the pressing temperature is 100°C, the pressure is 0.1MPa, cooling and winding. Obtain a composite material for construction with long-term waterproof, high and low temperature resistance, weather resistance, ultraviolet (UV) blocking, heat insulation, flame retardant, moisture permeability, moisture resistance, breathability, environmental protection, 100% bacteria blocking, high strength, etc. . Among them, the average value of the peel force GB8808-1988 test result is 3.0N / 15cm. The high and low temperature resistance test is GBT2423.22-2012 standard test for more than 3000 times of thermal shock, and the weather resistance test is ASTM D-3105. Photometer test blocks ultraviolet (UV) 95%, infrared blocking 98%, flame retardant test is EN IS...

Embodiment 3

[0098] With the laminating product prepared in embodiment two, the film surface continues to be mixed with 50g / m 2 The polyolefin PP non-woven fabric is sprayed and pasted with SIS type hot melt adhesive, and the weight of the glue is 2g / m 2 , the production line speed is 100m / min, the pressing temperature is 100°C, the pressure is 0.1MPa, cooling and winding. Obtain a composite material for construction with long-term waterproof, high and low temperature resistance, weather resistance, ultraviolet (UV) blocking, heat insulation, flame retardant, moisture permeability, moisture resistance, breathability, environmental protection, 100% bacteria blocking, high strength, etc. . Among them, the average value of the peel force GB8808-1988 test result is 2.0N / 15cm. The high and low temperature resistance test is GBT2423.22-2012 standard test for more than 4000 times of thermal shock, and the weather resistance test is ASTM D-3105. Photometer test blocks ultraviolet light (UV) 98%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com