Software development platform for embedded industrial control instrument

A software development platform and embedded technology, applied in the direction of program control devices, etc., can solve the problems that others cannot replicate, promote, develop and maintain successful experience, consume huge resources and losses, development tools, and compilation environments are different, etc., to achieve The effects of reducing repetitive development work, improving R&D efficiency, and reducing product development and post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

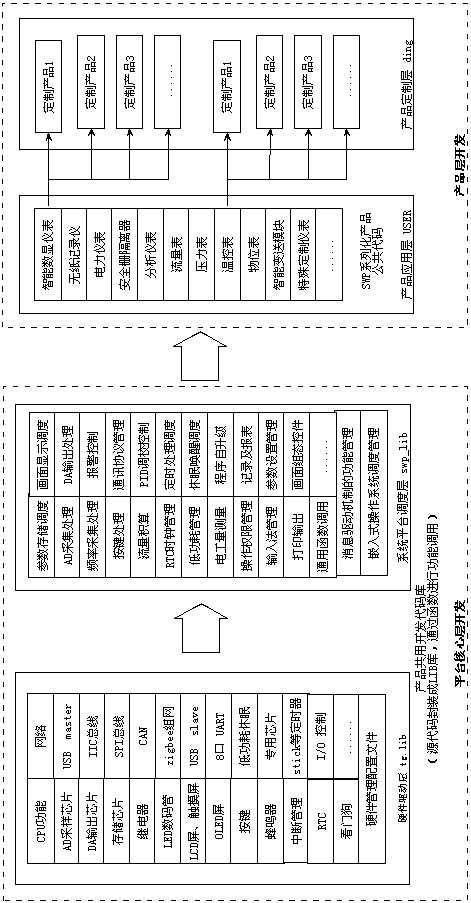

[0011] Embedded industrial control instrument software development platform of the present invention, such as figure 1 As shown, it is designed in four layers, including a hardware driver layer, a system platform scheduling layer, a product application layer and a product customization layer. The hardware driver layer and the system platform scheduling layer constitute the platform core layer, and the product application layer and the product customization layer Constitute the product layer; the hardware driver layer includes the driver code of the relevant hardware modules of the industrial control instrument, the system platform scheduling layer includes the code of the kernel software related scheduling management function developed for the industrial control instrument, and the product application layer includes various serialization The public code corresponding to the product, the product customization layer includes the customization code corresponding to each specific p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com