Continuous vacuum dynamic sublimating and condensing machine

A desublimation machine, dynamic technology, applied in the field of heat exchange, can solve the problems of harsh operating conditions of desublimates, increase of side reactions and side reaction products, affecting product quality and yield, etc., so as to reduce side reactions and increase Side reaction impurities, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

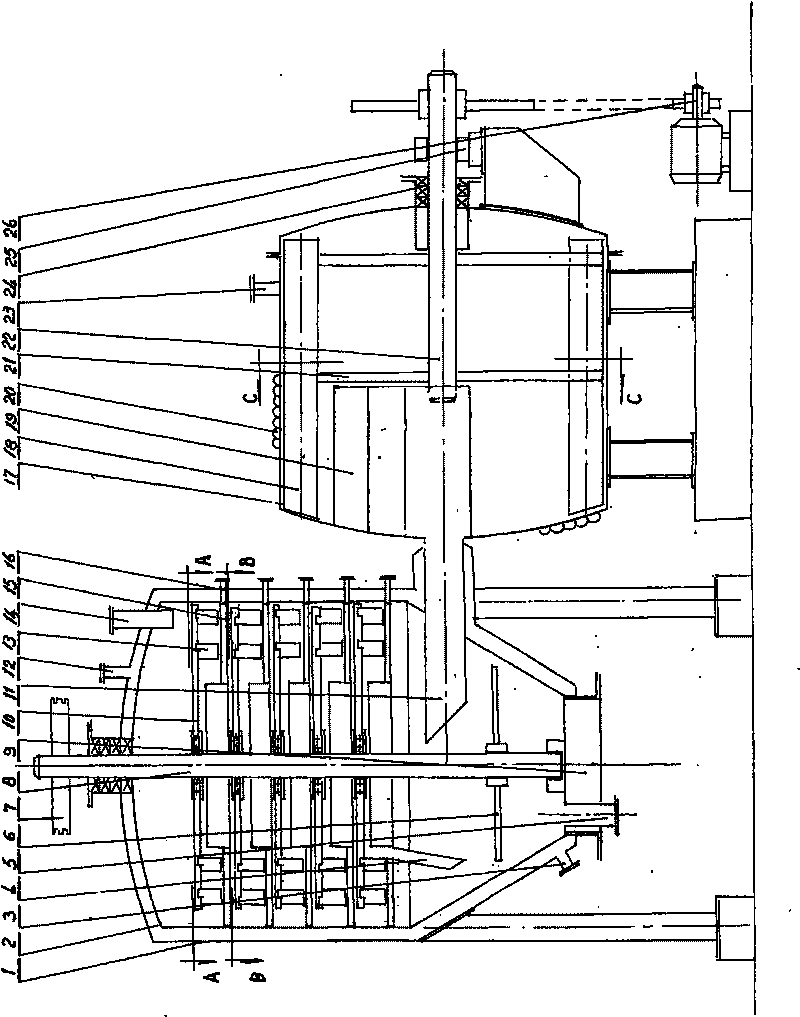

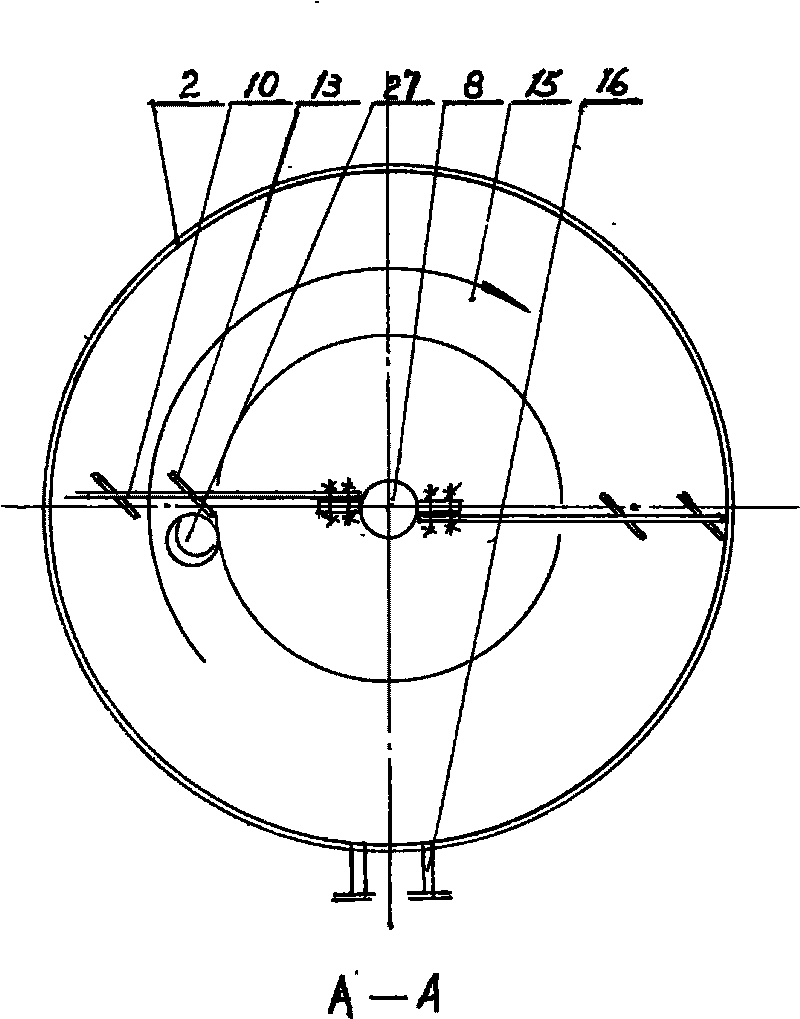

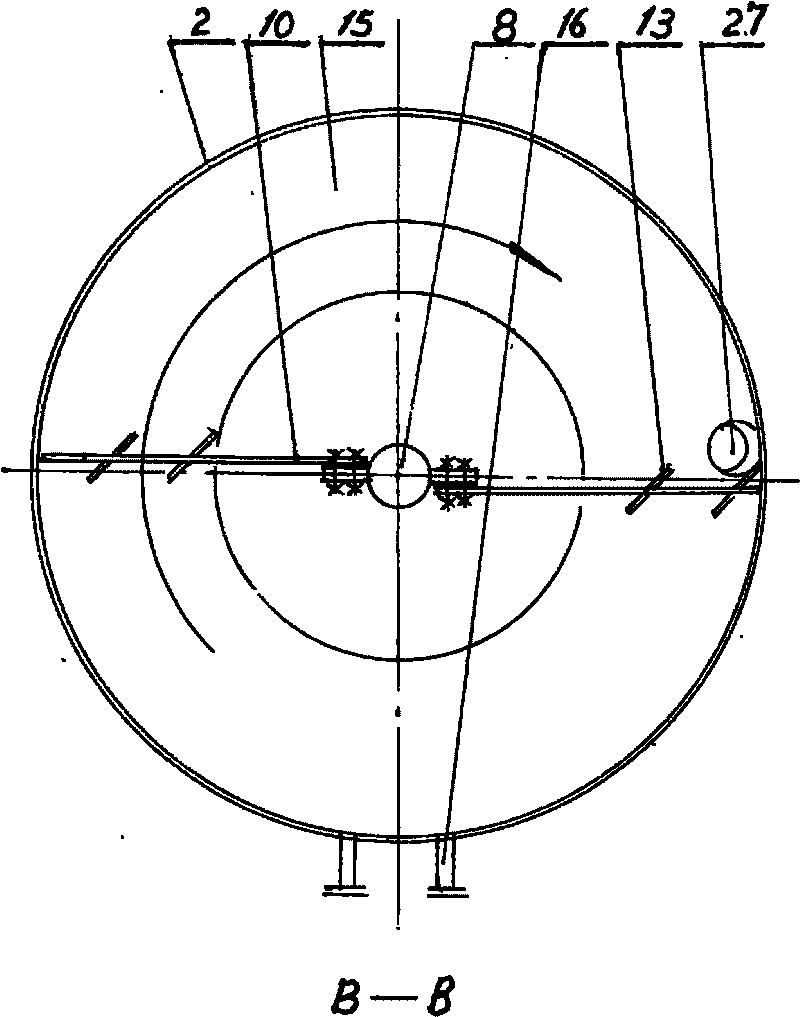

[0011] Embodiments of the present invention are further described in conjunction with the accompanying drawings, figure 1 , continuous vacuum dynamic sublimation and desublimation machine shown in 2 and 3, which includes a thermal oil heating jacket (1), cylinder body (2), thermal oil inlet and outlet (3, 12), residue feeding pipe (4) , residue outlet (5), residue scraper rod (6), driving pulley (7), scraper shaft (8), barrel manhole (9), rotary scraper rod (10), sublimation gas outlet pipe (11) , scraping rake (13), feed inlet (14), sublimation flat plate (15), flat plate hot oil inlet and outlet (16), desublimation cylinder (17), rotary copying chute (18), powder Body distributor (19), semicircular cooling water coil (20), copying rotating rod (21), copying rotating shaft (22), vacuum suction port (23), shaft seal (24), bearing seat (25) and Driving machine (26) etc. are formed. Its characteristics are: the continuous vacuum dynamic sublimation and desublimation machine is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com