Thermoplastic resin film laminate and preparation method thereof

A thermoplastic resin, laminate technology, applied in synthetic resin layered products, chemical instruments and methods, lamination and other directions, can solve the problems of curling in the film, restricting the application of thermoplastic resin film, and cutting unchanged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

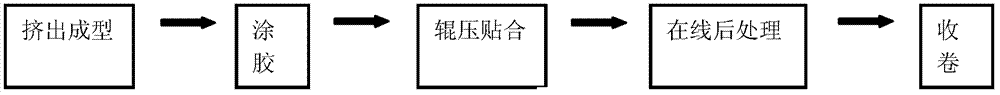

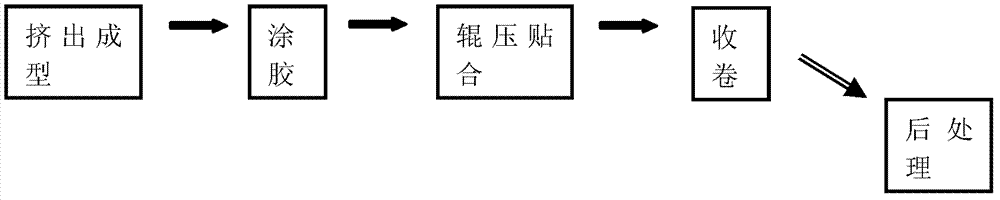

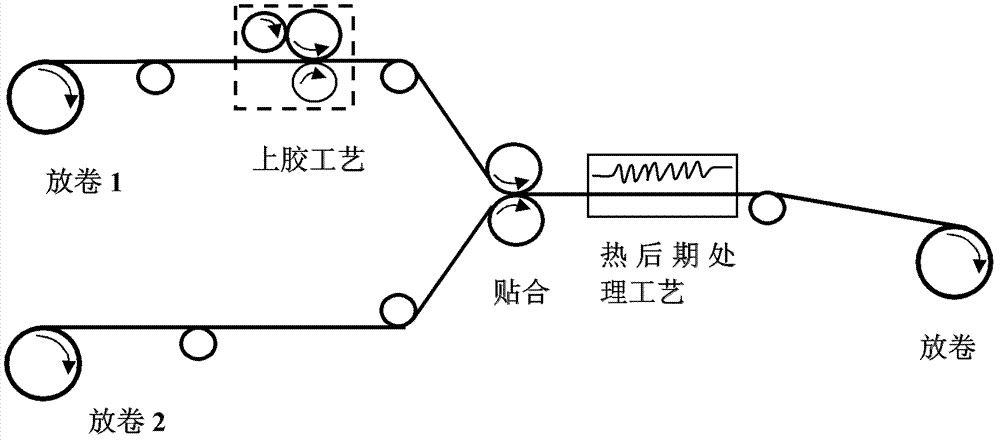

Method used

Image

Examples

Embodiment 1

[0059] After 12μm polyurethane thermoplastic resin film and 190g / m2 gram weight polyester polyester four-sided stretch knitted fabric are laminated with reactive hot melt polyurethane glue, the glue weight is 6g / m2 and the production line speed is 30m / min, the laminated product is subjected to thermal post-treatment (hot pressing roll method) on-line at a temperature of 100°C, a pressure of 1.0 MPa, and cooling and winding. Then the glue is matured. The surface is smooth, the fabric is not curled toward the film surface, the softness ISO 17235-2002 test result is 3.4, the peel force GB8808-1988 test result is 6.0N / 15cm, and the softness test result of the laminated product without online thermal post-treatment It is 2.9, the peel force GB8808-1988 test result average is 4.5N / 15cm, and the appearance is curled.

Embodiment 2

[0061] The 5μm polyetherester thermoplastic resin film and 40g / m2 polyolefin PP non-woven fabric are sprayed and bonded with SIS type hot melt adhesive. The glue weight is 0.8g / m2 and the production line speed is 100m / min. The product undergoes online thermal post-treatment (hot press roll method), temperature 100 ℃, 1.0 MPa pressure, cooling and winding. The obtained surface is smooth, the non-woven fabric is not curled to the film surface, the softness ISO 17235-2002 test result is 6.2, the peel force JIS L1096 test result is 1.2N / 15cm, and the softness test of the laminated product without online thermal post-treatment The result is 5.0, and the average value of the peel force GB8808-1988 test result is 0.9N / 15cm.

Embodiment 3

[0063] The film surface of the laminated product prepared in Example 2 is sprayed and bonded with a 20g / m2 polyolefin PP non-woven fabric using SIS type hot melt adhesive. The glue weight is 1g / m2 and the production line speed is 100m. / min, the laminated product is subjected to online thermal post-treatment (hot pressing roll method) at a temperature of 100°C, a pressure of 1.0 MPa, and cooling and winding. The surface is smooth, the non-woven fabric is not curled toward the film surface, and there is no glue opening. The softness ISO 17235-2002 test result is 5.2, the peel force GB8808-1988 test result is 0.8N / 15cm, and the sticker without online thermal post-treatment The softness test result of the combined product is 4.8, and the average value of the peel force GB8808-1988 test result is 0.6N / 15cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com