Method of preparing high electron mobility transistor (HEMT) on large-sized Si substrate

A high electron mobility, field effect transistor technology, applied in crystal growth, chemical instruments and methods, from chemically reactive gases, etc., can solve problems such as high defect density, poor mobility of Al atoms, warping, etc. Thermal conductivity, stress and defect resolution, warpage mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

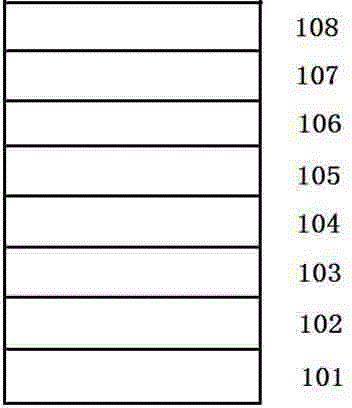

[0026] Use Aixtron company, tightly coupled vertical reaction chamber MOCVD growth system. During the growth process, trimethylgallium (TMGa) and trimethylaluminum (TMAl) were used as group III sources, ammonia (NH 3 ) as a Group V source, silane (SiH 4 ) as an n-type dopant source, dimagnesocene (Cp 2 Mg) as a p-type dopant source, the Si substrate 101 was first heated to 1080° C. in the MOCVD reaction chamber, and the 2 Under the atmosphere, use TMGa, TMAl as group III source, NH 3 As a V source, a 0.1 μm thick AlN nucleation layer was grown; then, at 1080 °C, H 2 Under the atmosphere, feed TMAl and TMGa as Group III sources, NH 3 As a group V source, a 0.5 micron thick AlGaN seed layer 102 was grown. Aligned multilayer carbon nanotubes were grown by low-pressure chemical vapor deposition (LPCVD). During the growth process, acetylene was used as the carrier gas, and 5nm Fe was used as the catalyst. The diameter of the grown carbon nanotubes is 15 nm. Through growth a...

Embodiment 2

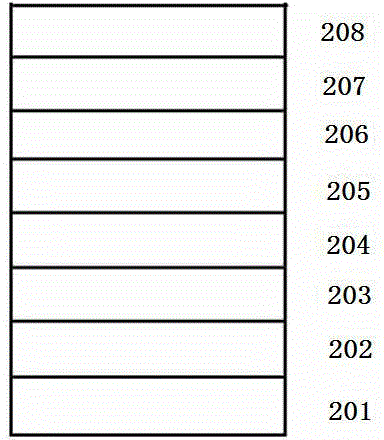

[0028] Use Aixtron company, tightly coupled vertical reaction chamber MOCVD growth system. During the growth process, trimethylgallium (TMGa) and trimethylaluminum (TMAl) were used as group III sources, ammonia (NH 3 ) as a Group V source, silane (SiH 4 ) as an n-type dopant source, dimagnesocene (Cp 2 Mg) as a p-type dopant source, the Si substrate 201 was first heated to 1080° C. in an MOCVD reaction chamber, and 2 Under the atmosphere, use TMGa, TMAl as group III source, NH 3 As a V source, a 0.1 μm thick AlN nucleation layer was grown; then, at 1080 °C, H 2 Under the atmosphere, feed TMAl and TMGa as Group III sources, NH 3 As a group V source, a 0.5 micron thick AlGaN seed layer 202 was grown. Aligned multilayer carbon nanotubes were grown by low-pressure chemical vapor deposition (LPCVD). During the growth process, acetylene was used as the carrier gas, and 5nm Fe was used as the catalyst. The diameter of the grown carbon nanotubes is 15 nm. Through growth and we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com