Soft-to-hard film sticking process and film sticking product

A film and process technology, applied in the field of 3D display equipment processing, can solve problems such as display panel warpage, and achieve the effect of reducing deformation, ensuring smooth implementation, and reducing tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

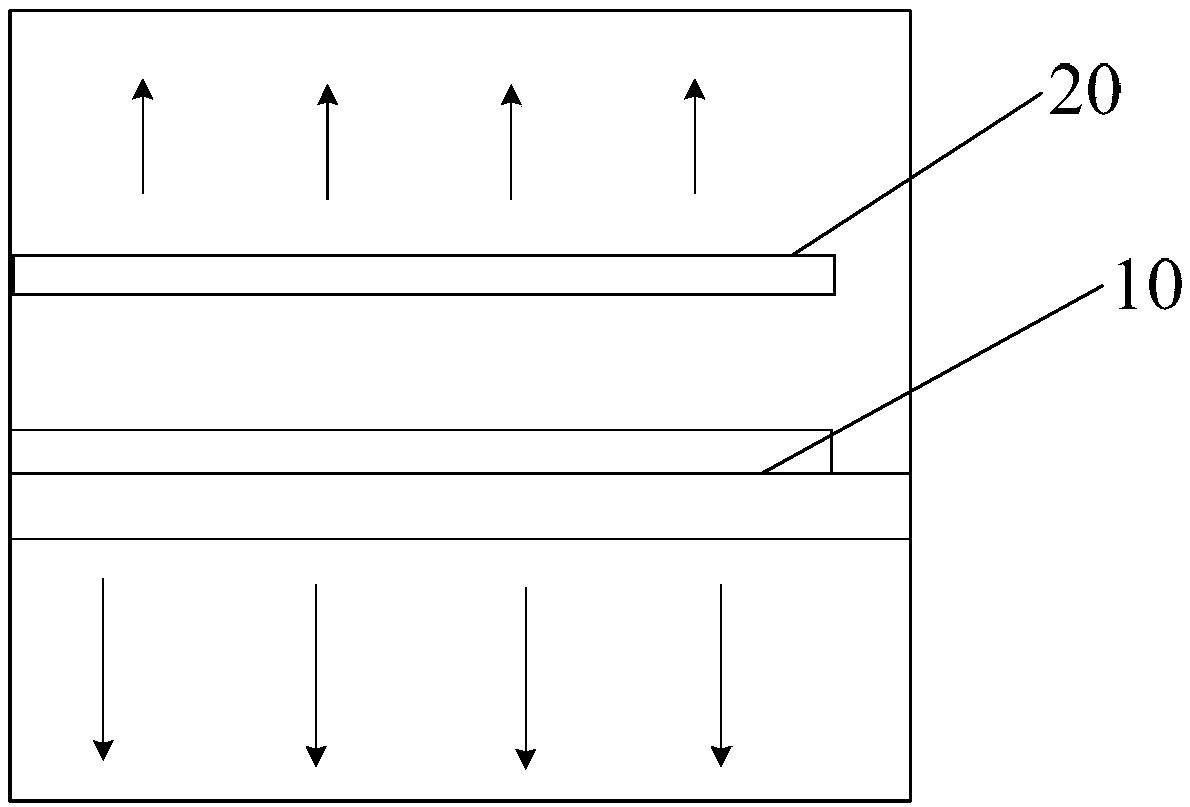

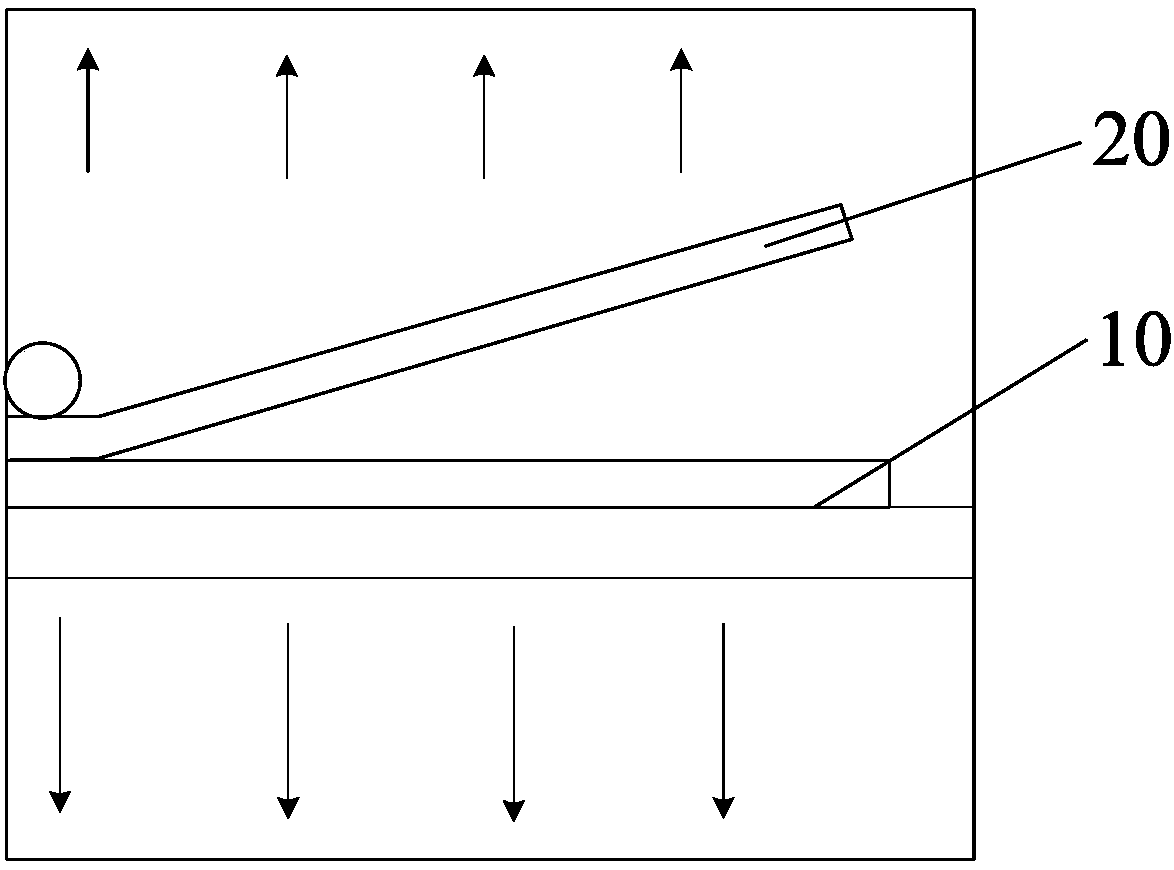

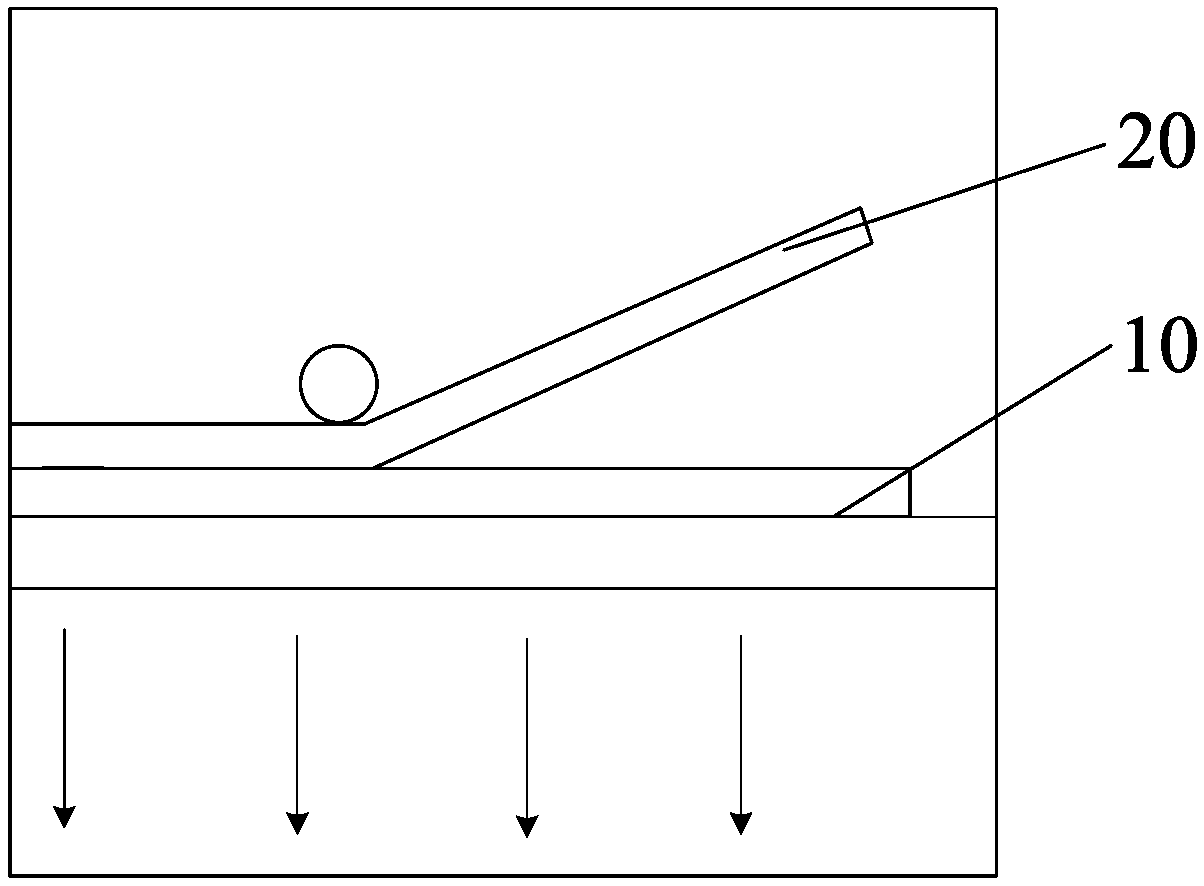

[0064] Using a PET layer with silicone pressure-sensitive adhesive as a flexible protective film, the hardness of the flexible protective film is..., placing 10 3D display panel components on the base, and setting the flexible protective film above the 3D display panel components , the upper and lower parts of the hard plane component to be filmed are evacuated respectively, and the vacuum degree of the lower part is controlled to be -50KPa, and the upper part is -20KPa; the flexible protective film is pressed onto the 3D display panel component by using rollers Start end: Stop vacuuming above the hard plane component and use rollers to roll the flexible protective film until the film sticking of the hard plane component is completed. The rolling pressure is controlled to 25N, and the moving speed of the roller is 80mm / s. Then use a plug gauge on the marble platform to measure the GAP value from the lower surface of the 3D display panel assembly to the marble platform (the test...

Embodiment 2

[0078] A PET layer provided with a silicone pressure-sensitive adhesive is used as a flexible protective film, the hardness of the flexible protective film is 4H, 10 3D display panel components are placed on the abutment, and the flexible protective film is arranged above the 3D display panel component , the top and bottom of the hard plane component to be filmed are vacuumed respectively, and the vacuum degree of the lower part is controlled to be -20KPa, and the vacuum degree of the upper part is -0.01KPa; the flexible protective film is pressed onto the 3D display panel component by using rollers. Close the starting end; stop vacuuming the top of the hard plane component and use the roller to roll the flexible protective film until the film of the hard plane component is completed, control the rolling pressure to 25N, and the moving speed of the roller to 80mm / s . Then measure the GAP value from the lower surface of the 3D display panel assembly to the marble platform with ...

Embodiment 3

[0082] A PET layer provided with a silicone pressure-sensitive adhesive is used as a flexible protective film, the hardness of the flexible protective film is 4H, 10 3D display panel components are placed on the abutment, and the flexible protective film is arranged above the 3D display panel component , the top and bottom of the hard plane component to be filmed are vacuumed separately, and the vacuum degree of the lower part is controlled to be -50KPa, and the vacuum degree of the upper part is -30KPa; the flexible protective film is pressed on the 3D display panel component by rollers Start end: stop vacuuming above the hard plane component and use rollers to roll the flexible protective film until the film sticking of the hard plane component is completed. Control the rolling pressure to 25N and the speed of the roller to 80mm / s. Then measure the GAP value from the lower surface of the 3D display panel assembly to the marble platform with a plug gauge on the marble platform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com