Polycarbonate polyol type spraying polyurea elastomer coating and preparation method

A polyurea elastomer, polycarbonate technology, applied in the direction of coating, can solve the problem of undiscovered, and achieve the effect of reducing edge warping and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

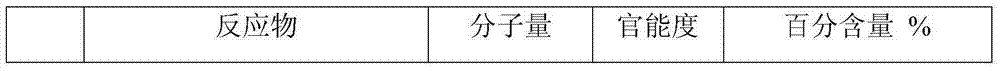

[0024] A component:

[0025]

[0026]

[0027] Synthesis:

[0028] 1. Add polycarbonate polyol, polyether polyol, dibutyl phthalate, and catalyst into the reaction kettle, start stirring, heat up to 110°C, vacuumize for 3 hours to remove water, and start to cool down to 60°C;

[0029] 2. Add isocyanate, heat up to 80°C after the temperature stabilizes, and react for 3 hours;

[0030] 3. Check the NCO% content every half hour, and the material can be discharged when it reaches 13.2%;

[0031] B component:

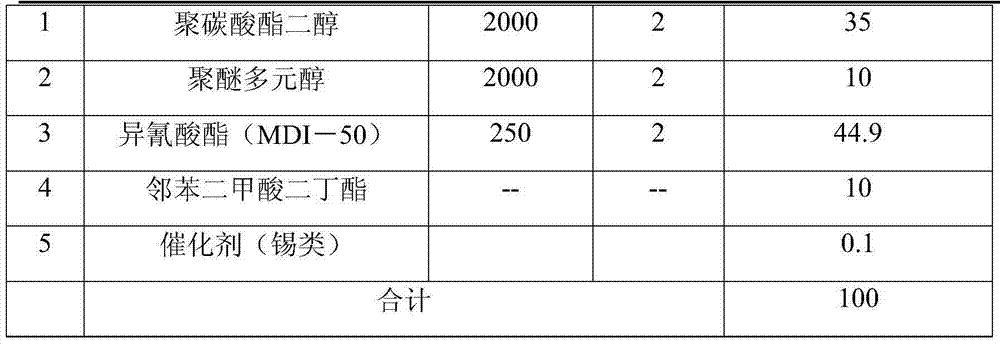

[0032]

[0033] Synthesis:

[0034] 1. Put the above-mentioned raw materials into the reaction kettle one by one, vacuumize and stir at 110-120°C for 3 hours, and then discharge.

[0035] Instructions:

[0036] Use special spraying equipment for spraying polyurea for construction, requiring the material to be heated above 50°C.

[0037] Immediately after spraying, put it into the standard curing room for curing, and test the indicators after seven days;

[00...

Embodiment 2

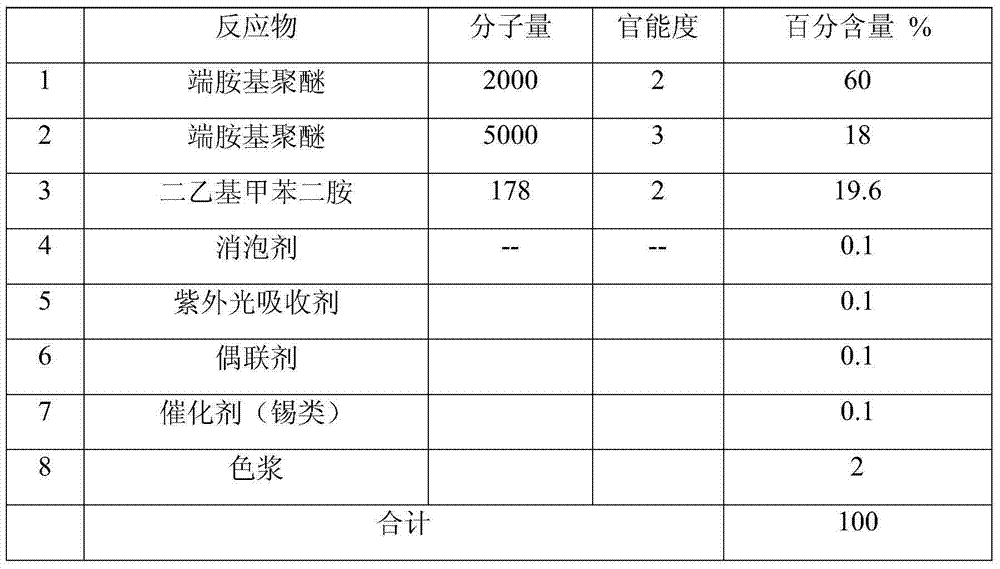

[0042] A component

[0043]

[0044] Synthesis:

[0045] 1. Add polycarbonate alcohol, polyether, dibutyl phthalate, and catalyst into the reaction kettle, start stirring, heat up to 110°C, remove water under vacuum for 3 hours, and start to cool down to 60°C;

[0046] 2. Add isocyanate, heat up to 80°C after the temperature stabilizes, and react for 3 hours;

[0047] 3. Check the NCO% content every half hour, and the material can be discharged when it reaches 16.5%;

[0048] B component

[0049]

[0050]

[0051] Synthesis:

[0052]1. Put the above-mentioned raw materials into the reaction kettle one by one, vacuumize and stir at 110-120°C for 3 hours, and then discharge.

[0053] Instructions:

[0054] Use special spraying equipment for spraying polyurea for construction, requiring the material to be heated above 50°C.

[0055] Immediately after spraying, put it into the standard curing room for curing, and test the indicators after seven days;

[0056] Its m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com