Woven fabric structure of glass fiber leno mesh and weaving method thereof

A glass fiber and fabric weave technology, applied in leno fabrics, leno fabrics, fabrics, etc., can solve the problems of large tension difference between the upper and lower layers, broken warp yarns, difficult production, etc., and achieves low cost and fabric weave. The effect of stable structure and simple and convenient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

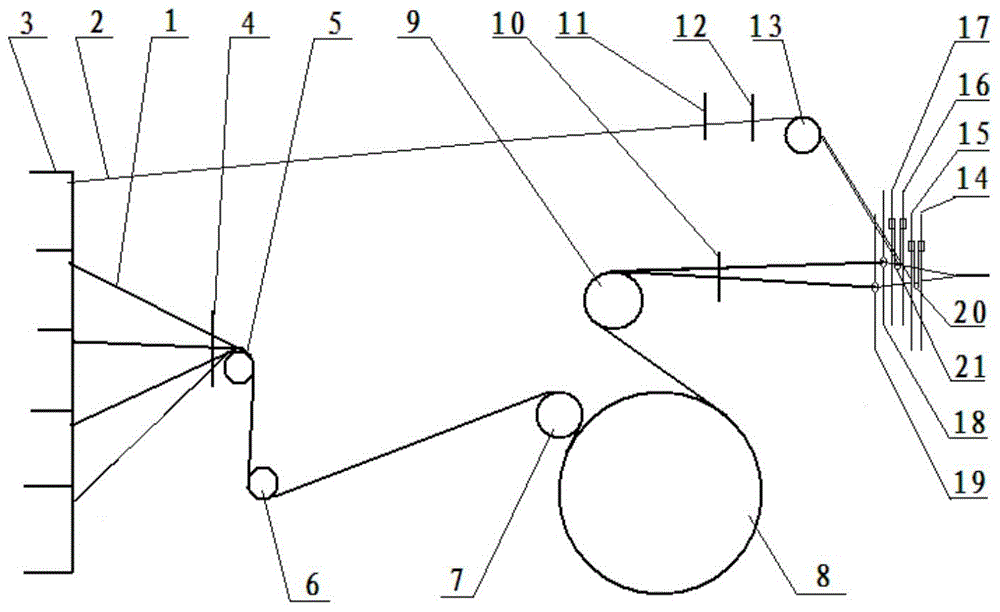

[0024] Embodiment 1: In this embodiment, one twisted warp and one ground warp form a twisted group.

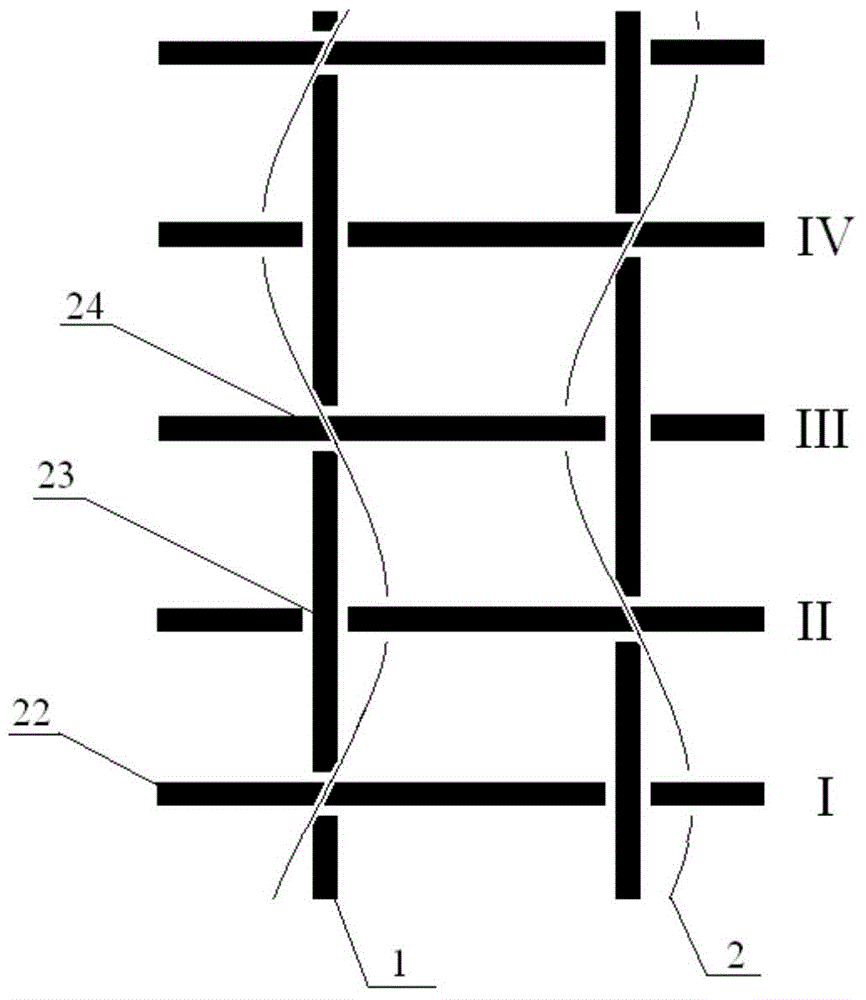

[0025] The structure of the fabric is as figure 2 As shown: wherein, the ground warp 1 and the weft yarn 22 are interlaced up and down one by one to form a plain weave, and the intersection of the ground warp 1 and the weft yarn 22 in the plain weave forms an interweaving where the ground warp is arranged at the upper interweaving point 23 or the weft yarn is arranged at the top Point 24, the layout of ground warp 1 and weft yarn 22 at any adjacent interweaving point is opposite, and the warp yarn also includes skein warp 2, and the skein warp 2 extends along the extension direction of the ground warp, sequentially and regularly surrounds The same ground warp is regularly shuttled and extended to form twisted groups. The law is that the interweaving points that meet the weft yarn layout are obliquely covered, and the interweaving points that meet the ground warp layout are pe...

Embodiment 2

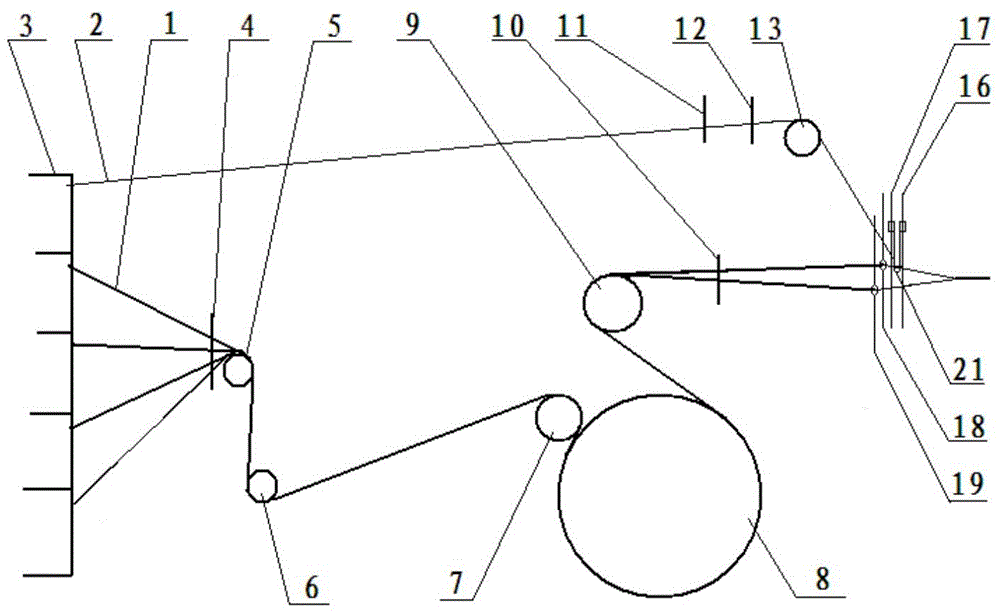

[0028] Embodiment 2: In this embodiment, one twisted warp and two ground warps form a twisted group.

[0029] The structure of the fabric is as Figure 4As shown: wherein, the ground warp 1 and the weft yarn 22 are interlaced up and down one by one to form a plain weave, and the intersection of the ground warp 1 and the weft yarn 22 in the plain weave forms an interweaving where the ground warp is arranged at the upper interweaving point 23 or the weft yarn is arranged at the top Point 24, the layout of ground warp 1 and weft yarn 22 at any adjacent interweaving point is opposite, and the warp yarn also includes skein warp 2, and the skein warp 2 extends along the extension direction of the ground warp, sequentially and regularly surrounds The same ground warp group composed of two adjacent ground warps is regularly shuttled and extended to form a twisted group. The rule is that the twisted warps are twisted along two adjacent ground warps to form a twisted group. The turning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com