Main shaft device for numerical controlled gear hobbing machine

A technology of spindle device and gear hobbing machine, which is applied in the direction of gear tooth manufacturing device, gear cutting machine, and components with teeth, etc. It can solve the problems of long tool setting time, reduced spindle precision, easy wear of bearings, etc., and achieve high work efficiency and precision Excellent retention and high spindle accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

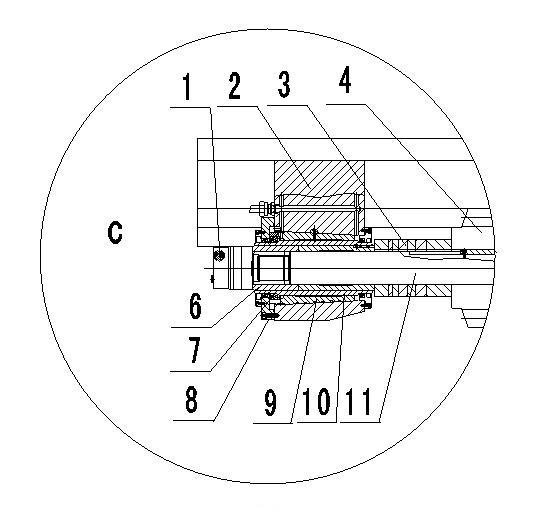

[0023] Such as figure 1 As shown, the main shaft mechanism of the CNC gear hobbing machine of the present invention includes a tool bar assembly, a tool bar assembly clamping mechanism and a tool change mechanism, wherein the structure of the tool bar assembly is: the hob 4 is fixed on the middle part of the tool bar 11 through a flat key 12, and Its two sides are equipped with adjusting pad 3, the shaft sleeve 6 is installed on the left side of the adjusting pad 3, the left end of the knife rod 11 is equipped with a lock nut 1, the right end has a keyway, and the tail end of the taper handle is equipped with a knife rod Rivet 4.

example 2

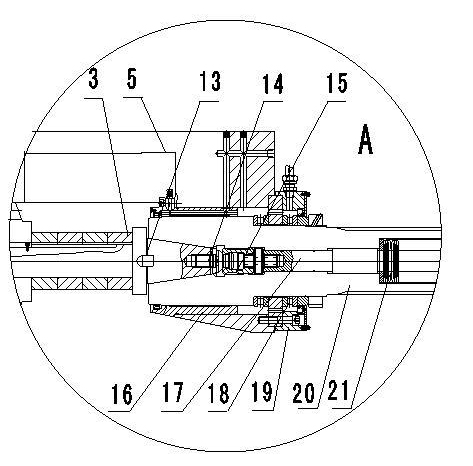

[0025] Such as figure 2 As shown, the clamping mechanism of the tool bar assembly is: a keyway is provided on both sides of the left end surface of the main shaft 20, a square key 13 matching the keyway at the right end surface of the tool bar 11 is housed in the keyway, and a valve is housed in the inner hole of the main shaft 20. Claw assembly 15 , the valve claw hook in the valve claw assembly 15 corresponds to the cylindrical boss of the knife bar pull stud 14 .

[0026] The main shaft centering and positioning mechanism includes a rear static pressure shoe 16 on the left side in the cylindrical hole at the right end of the hob body 5 and a two-way thrust roller bearing 8 on the right side. The left end of main shaft 20 passes in rear static pressure pad 16 cylindrical holes, and the left side of bidirectional thrust roller bearing 18 pushes on the shaft shoulder of main shaft 20 left parts.

example 3

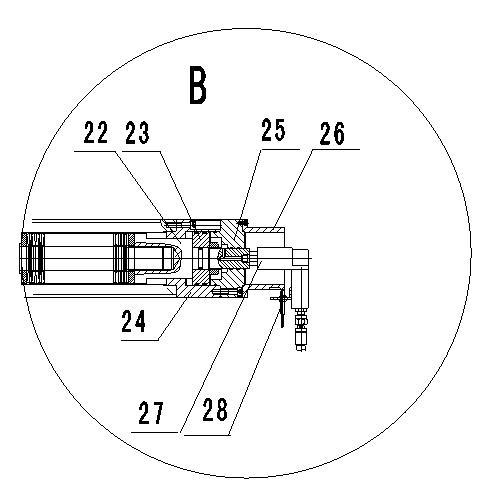

[0028] Such as image 3 As shown, the structure of the tool changing mechanism is; the valve claw assembly 15 is threadedly connected with the left end of the pull rod 17, and the right end of the pull rod 17 is threaded with the piston rod 22; Disc spring 21 is arranged; Oil cylinder body 24 is contained in the afterbody of main shaft 20, and its right end is equipped with flange plate 25, support 26 successively;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com