Inner gear machining method and special gear shaping clamp

A processing method and technology for internal gears, which are applied in gear tooth manufacturing devices, manufacturing tools, metal processing equipment, etc., can solve the problems of rapid tool wear, large machining allowance, and low processing efficiency, so as to reduce wear and improve gear teeth. The effect of machining accuracy and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

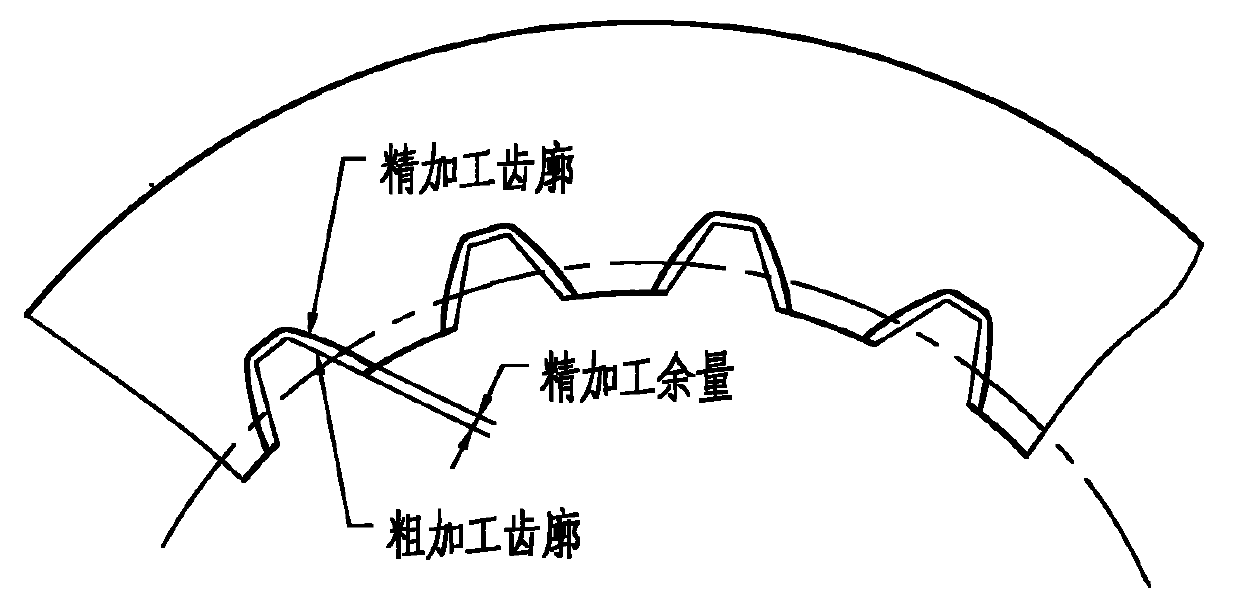

[0016] figure 1 Taking the involute internal gear as an example, the technical process of the internal gear processing method proposed by the present invention is explained. In the figure, the thin line tooth profile is the rough machining process, and the trapezoidal profile cutter and indexing mechanism are used on the ordinary slotting machine to process it by forming method. The formed intermediate tooth profile; the thick line is the final tooth profile formed by the gear shaping cutter on the gear shaping machine in the finishing process, and the part between the two tooth profiles is the reserved finishing allowance .

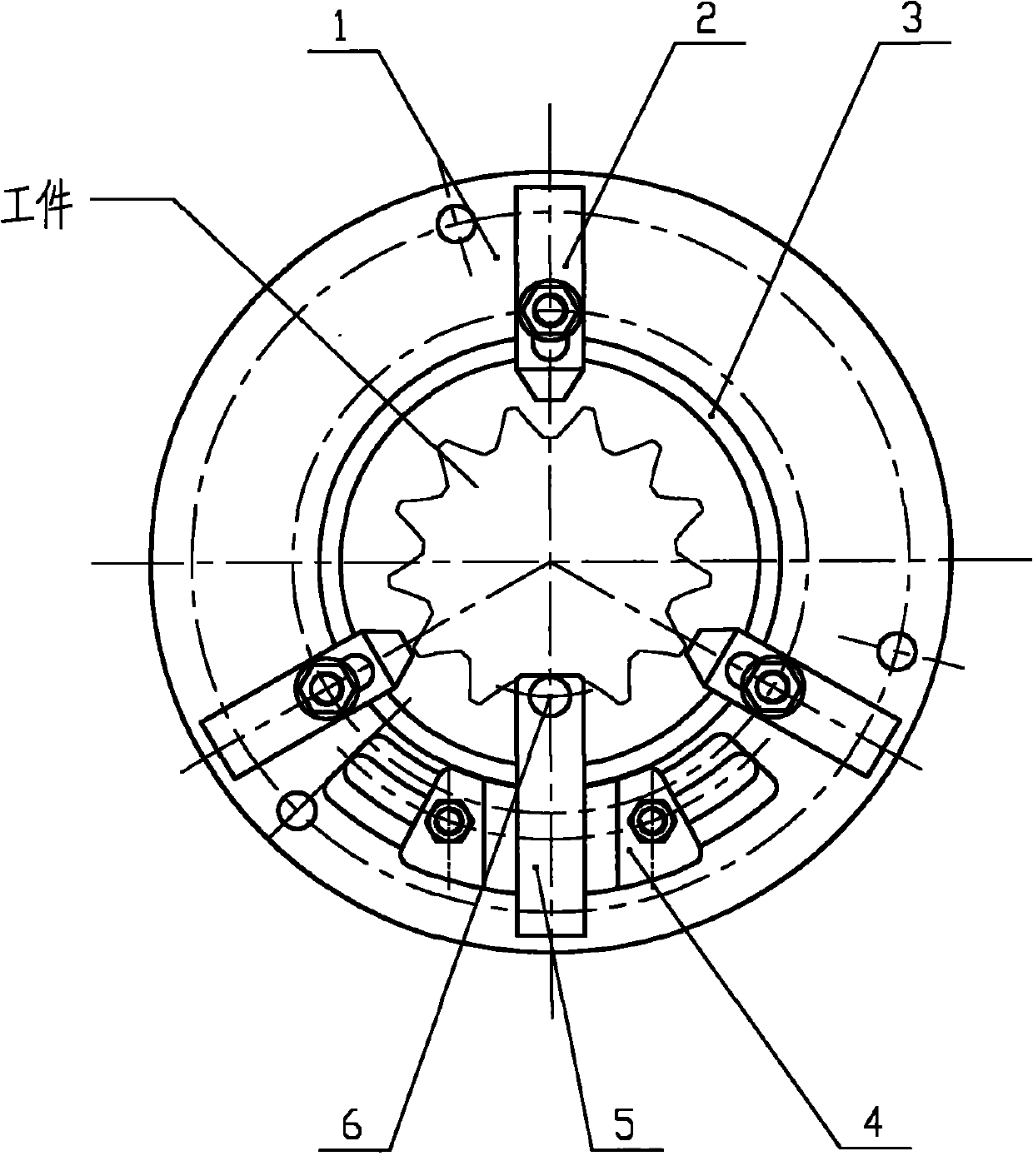

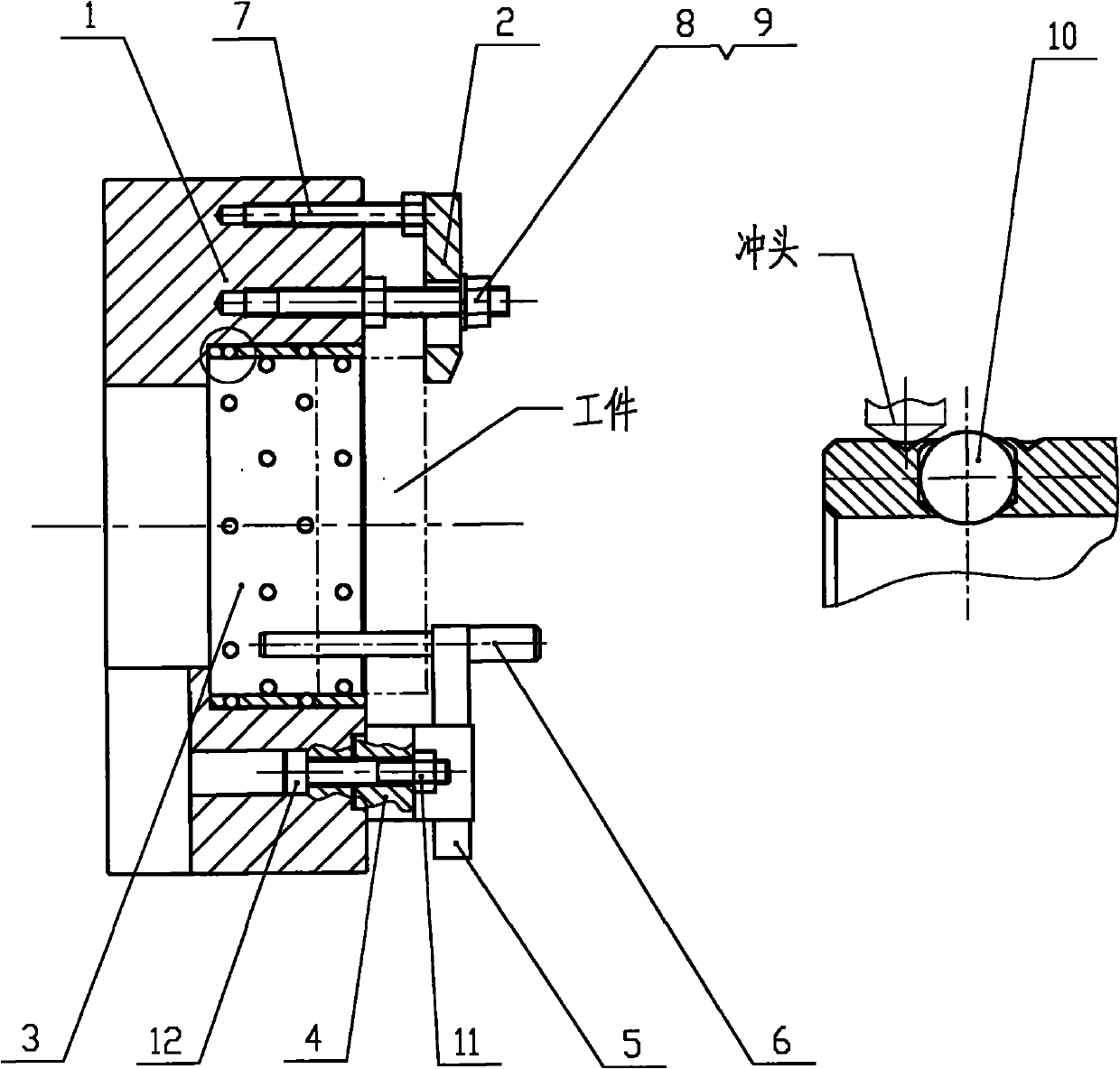

[0017] The structure and working principle of the special gear shaping fixture for internal gear processing proposed by the present invention can be obtained through figure 2 and image 3 Explain that the base 1 is installed on the gear shaping machine, and there is a counterbore on the base, in which the annular cage 3 is placed. There are a number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com