Fluid pump and excitation element

A technology of fluid pumps and piezoelectric elements, which is applied to pump elements, components of pumping devices for elastic fluids, variable displacement pump components, etc., can solve the problems of low output capacity, low reliability, and high cost, and achieve Effects of increasing output flow and output pressure, improving output performance, and high output flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

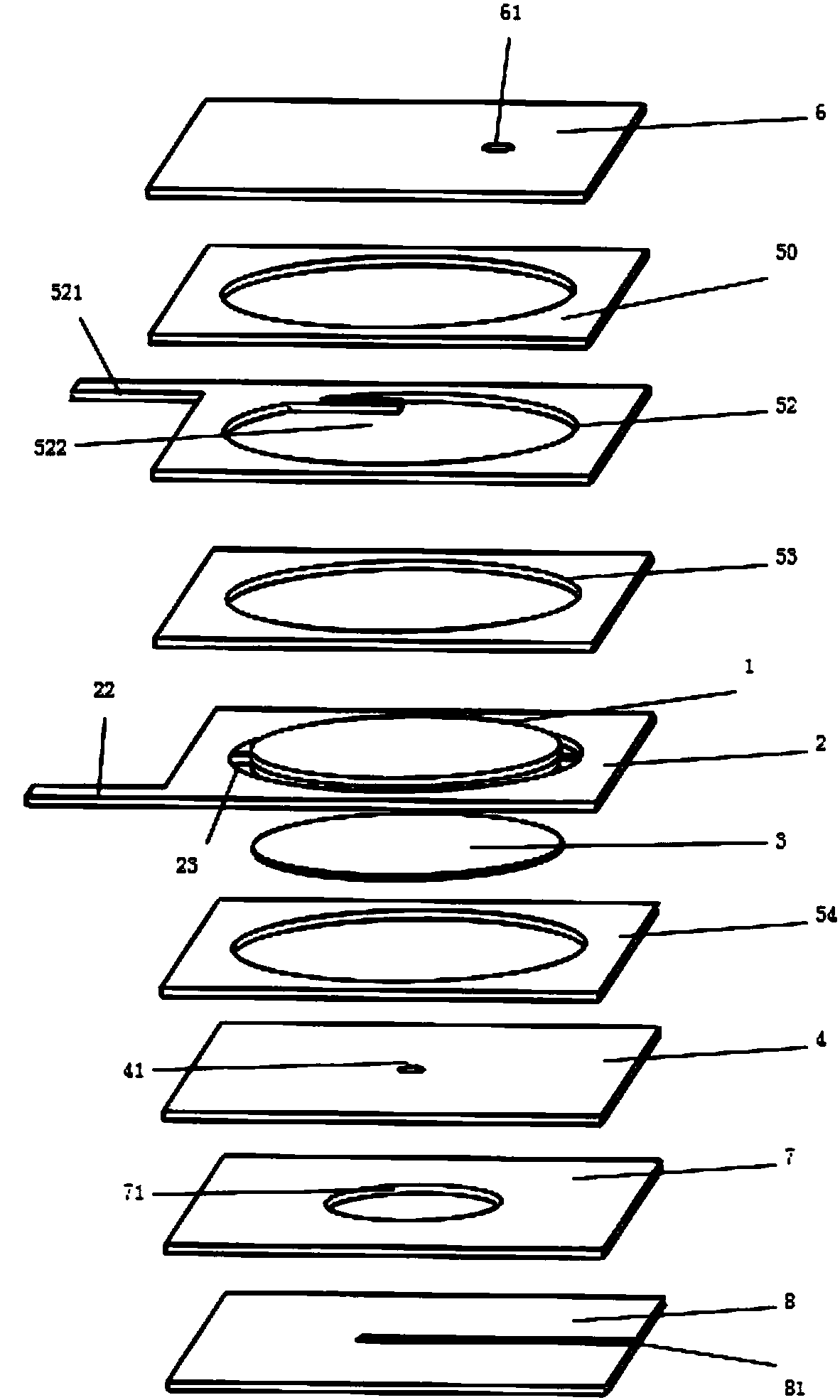

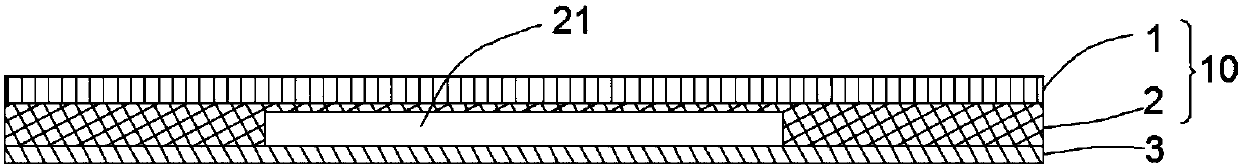

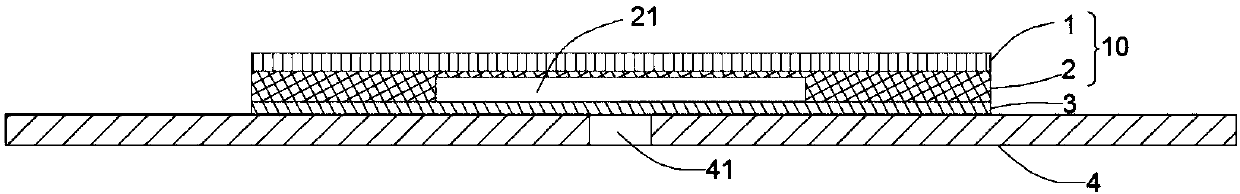

[0037] like figure 1 As shown, the fluid pump of this embodiment includes a piezoelectric vibrator 10, a vibrating diaphragm 3, and a surface 4, wherein the piezoelectric vibrator 10 includes a vibrating substrate 2 and a piezoelectric element 1 disposed on one side of the vibrating substrate 2, and the piezoelectric element 1 The piezoelectric vibrator 10 is formed centrally with the vibrating substrate 2 and bonded together to form a piezoelectric vibrator 10. The piezoelectric vibrator 10 can generate bending vibration from its central part to the peripheral part. The vibrating substrate 2 is made of metal such as stainless steel or phosphor bronze. Electrode films are formed on the upper and lower surfaces of the electric element 1, respectively. The electrodes on the lower surface are electrically connected to the vibrating substrate and form capacitive coupling. The electrodes on the upper surface are connected with conductor lines, and the conductor lines are connected t...

Embodiment 2

[0051] like Figure 5 As shown, the fluid pump of this embodiment is basically the same as that of Embodiment 1, the difference is that the fluid pump also includes a support plate 5 and an upper cover plate 6, the support plate 5 is arranged on the plane portion 4, and the two are hermetically connected, and the upper cover The plate 6 is arranged on the support plate 5, and the upper cover plate 6 and the support plate 5 are also connected in a sealed manner, thereby forming a cavity 51, wherein a through hole 61 is provided at the center of the upper cover plate 6 or other positions, through which The through hole 61 communicates with the outside atmosphere.

[0052] When not driven, the excitation element is relatively arranged on the plane part 4 in a contact manner. When driven by a power source, according to the principle described in Embodiment 1, the fluid is sucked through the central vent hole 41, and then the sucked fluid is discharged through the through hole 61....

Embodiment 3

[0054] like Figure 6 and Figure 7 Shown are the structural exploded view and cross-sectional view of the fluid pump of the third embodiment respectively. This embodiment is basically the same as the first embodiment, the difference is that the structure of the vibrating base plate 2 is improved, by Figure 6 It can be seen that the vibrating substrate 2 includes a central vibrating area, surrounding supporting parts, elastic connecting parts 23 and first wire welding parts 22 . Wherein, the elastic connecting part 23 is set as an elastic structure with a small elastic coefficient, so that the middle vibration region is softly supported by the surrounding support parts, so it can be considered that the elastic support will not hinder the bending vibration of the middle vibration region, that is, the vibration region is substantially in the A state of being unconstrained.

[0055] In addition, the fluid pump of this embodiment also includes an upper cover plate 6 , a first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com