Unequal-tooth-number screw profile for high-flow high-pressure three-screw pump

A three-screw pump, high-flow technology, applied to the components of the pumping device for elastic fluid, rotary piston type/swing piston type pump components, pumps, etc., can solve the problems of low output pressure and small specific flow, etc. , to achieve the effect of increased output pressure, short sealing line and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

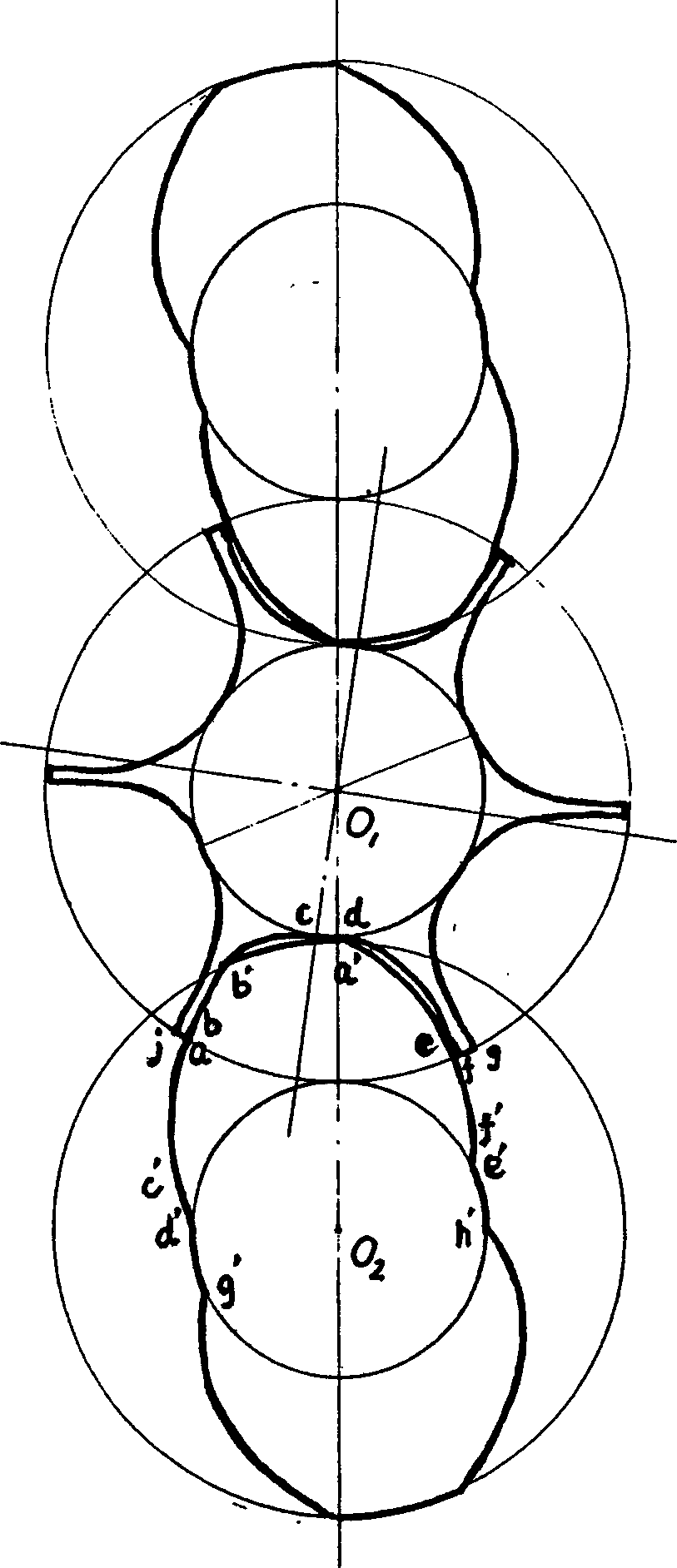

[0013] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0014] The screw pump of the present invention comprises three screws, two of which are double-start screws, and the other screw is a six-start screw.

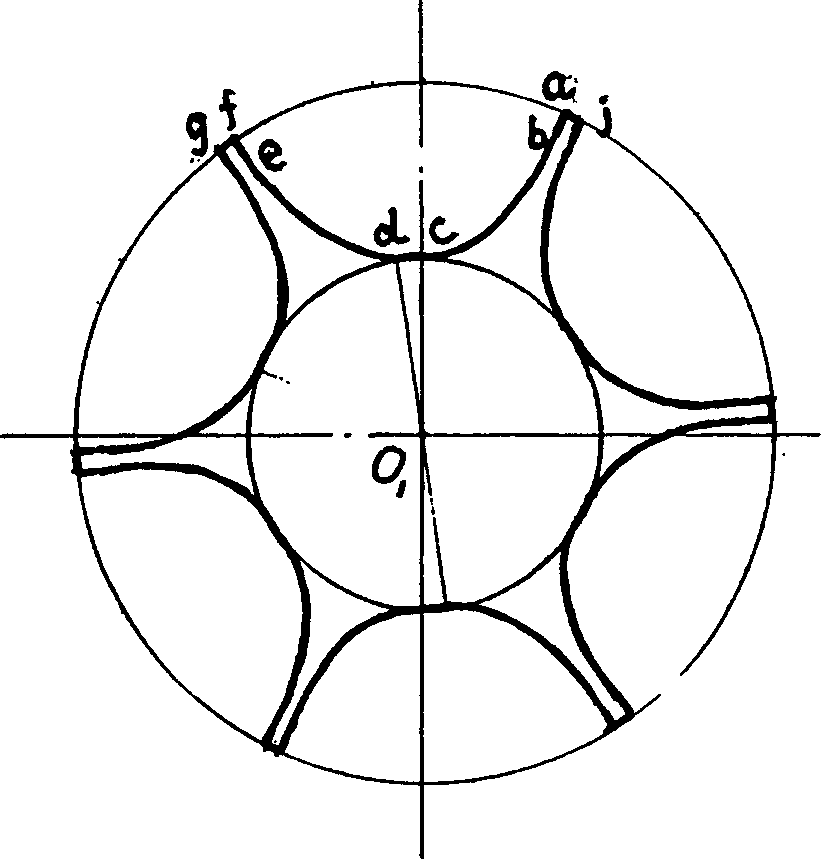

[0015] figure 1 Shows the shape of the radial cross-section of the six-head screw of the present invention. Each screw of the six-head screw has the same tooth shape and is evenly distributed along the circumference. One of the six-head screws is composed of a radial straight line ab, a generalized cycloid bc, and a dedendum arc Line cd, generalized cycloid de, radial straight line segment ef and addendum arc line fg are sequentially connected. Among them, the addendum arc line fg and the dedendum arc line cd are based on o 1 The arc of the center of the circle; the radius and radian of the root arc cd can be adjusted, the length of the radial straight line ab and ef can be adjusted, and ab and ef can also be arcs, cycloids...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com