Preparation method of high-corrosion-resistance and easy-to-process magnesium aluminum alloy composite plate strip materials

A technology of aluminum alloy plate and magnesium aluminum alloy, which is applied in metal rolling, chemical instruments and methods, metal layered products, etc., can solve the problems of low plastic deformation capacity at room temperature and poor corrosion resistance, and achieve improved corrosion resistance , good corrosion resistance, improve the effect of cold rolling plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

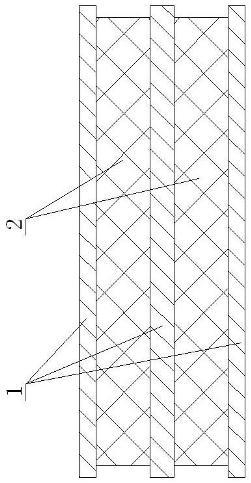

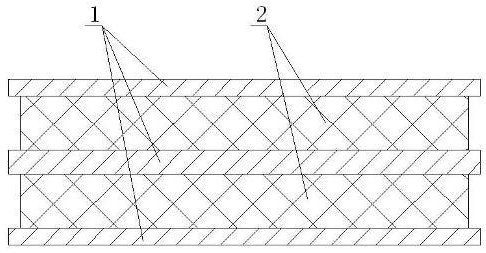

[0028] see figure 1 , a kind of preparation method of high corrosion resistance, easy processing magnesium-aluminum alloy composite board strip, is characterized in that comprising the following steps:

[0029] a), smooth

[0030] Leveling the magnesium alloy sheet and the aluminum alloy sheet respectively, and then trimming the edges so that the width of the magnesium alloy core layer 2 is 5 mm smaller than the width of the cladding aluminum sheet 1;

[0031] b), cleaning

[0032] First, clean the surface of the magnesium alloy plate and the aluminum plate to be compounded with ethanol with a mass percentage concentration of 20%, and clean the oil stains on the surface of the magnesium alloy plate and the aluminum plate to be compounded; NaOH solution for 3 minutes, rinse with clean water; then use HNO with a mass percentage concentration of about 5%% 3 Wash with the solution for 3 minutes; then rinse with clean water and dry with cold air;

[0033] c), hair removal

...

Embodiment 2

[0046] see figure 1 , a kind of preparation method of high corrosion resistance, easy processing magnesium-aluminum alloy composite board strip, is characterized in that comprising the following steps:

[0047] a), smooth

[0048] Leveling the magnesium alloy plate and the aluminum alloy plate respectively, and then trimming the edges so that the width of the magnesium alloy core layer 2 is 20 less than the width of the cladding aluminum plate 1;

[0049] b), cleaning

[0050] First, the surface of the magnesium alloy plate and the aluminum plate to be compounded is cleaned with ethanol with a mass percentage concentration of 60%, and the oil stains on the surface of the magnesium alloy plate and the aluminum plate to be compounded are cleaned; then the NaOH solution with a mass percentage concentration of 2% and a temperature of 55 Wash for 6 minutes, rinse with clean water; then use mass percentage concentration of about 10% HNO 3 Wash with solution for 6 minutes; then r...

Embodiment 3

[0063] see figure 1 , a kind of preparation method of high corrosion resistance, easy processing magnesium-aluminum alloy composite board strip, is characterized in that comprising the following steps:

[0064] a), smooth

[0065] Leveling the magnesium alloy sheet and the aluminum alloy sheet respectively, and then trimming the edges so that the width of the magnesium alloy core layer 2 is 30mm smaller than the width of the cladding aluminum sheet 1;

[0066] b), cleaning

[0067] First, the surface of the magnesium alloy plate and the aluminum plate to be compounded is cleaned with ethanol with a mass percentage concentration of 95%, and the oil stains on the surface of the magnesium alloy plate and the aluminum plate to be compounded are cleaned; Wash with NaOH solution for 10 minutes, rinse with water; then use HNO with a concentration of about 15% by mass 3 Wash with the solution for 10 minutes; then rinse with clean water and dry with cold air;

[0068] c), hair re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com