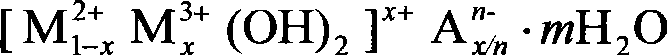

Method for preparing nano magnalium hydrotalcite and equipment thereof

A nano-magnesium, aluminum water technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of insufficient mixing, small reaction interface, slow reaction speed and diffusion speed, etc., to reduce costs and simplify production. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step A: Dissolve 200.0g of solid magnesium sulfate and 87.3g of solid aluminum sulfate (Mg / Al=3 (mol / mol) in 700ml water to form a mixed salt solution, and then weigh 192.5g of ammonium bicarbonate and dissolve it in 700ml of water Dubbed ammonium bicarbonate solution.

[0029] Step B: Start the metering pump, and add the saline solution and the ammonium bicarbonate solution into the static mixer reactor simultaneously.

[0030] Step C: Pour the synthetic reaction material flowing out of the reactor in step B into a 2000ml ripening tank, and then ripen under stirring. The stirring speed is 30 rpm, 80°C, and the time is 6 hours.

[0031] Step D: The mother liquor is separated by vacuum filtration.

[0032] Step E: washing, drying, and pulverizing: the materials in step D are separated from the mother liquor, washed with water for 3 times, dried, and pulverized to obtain nano-magnesium aluminum hydrotalcite.

Embodiment 2

[0034] Step A: Dissolve 100.0kg of solid magnesium sulfate and 43.6kg of solid aluminum sulfate (Mg / Al=3 (mol / mol) in 350l of water to make a mixed salt solution, and take another 96.2kg of ammonium bicarbonate and dissolve it in 350l of water Dubbed ammonium bicarbonate solution.

[0035] Step B: Start the metering pump, and add the saline solution and the ammonium bicarbonate solution into the static mixer reactor simultaneously.

[0036] Step C: Pour the synthetic reaction material flowing out of the reactor in step B into 1M 3 The airtight glass-lined reaction kettle is ripened under stirring. The stirring speed is 10 rpm, 120°C, and the time is 4 hours.

[0037] Step D: separating the mature nano-magnesium aluminum hydrotalcite from the mother liquor.

[0038] Step E: washing, drying, and pulverizing: the materials in step D are separated from the mother liquor, washed with water for 3 times, dried, and air-jet pulverized to obtain nano-magnesium aluminum hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com