Method for preparing full nanometer granule visible light area antireflection film by layer upon layer self-assembly method

A layer-by-layer self-assembly and nano-particle technology, which is applied in the field of preparing all-nano-particle anti-reflection film in the visible light region by layer-by-layer self-assembly method, can solve the problems of narrow wavelength range, achieve low cost, improve anti-reflection effect, and make equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

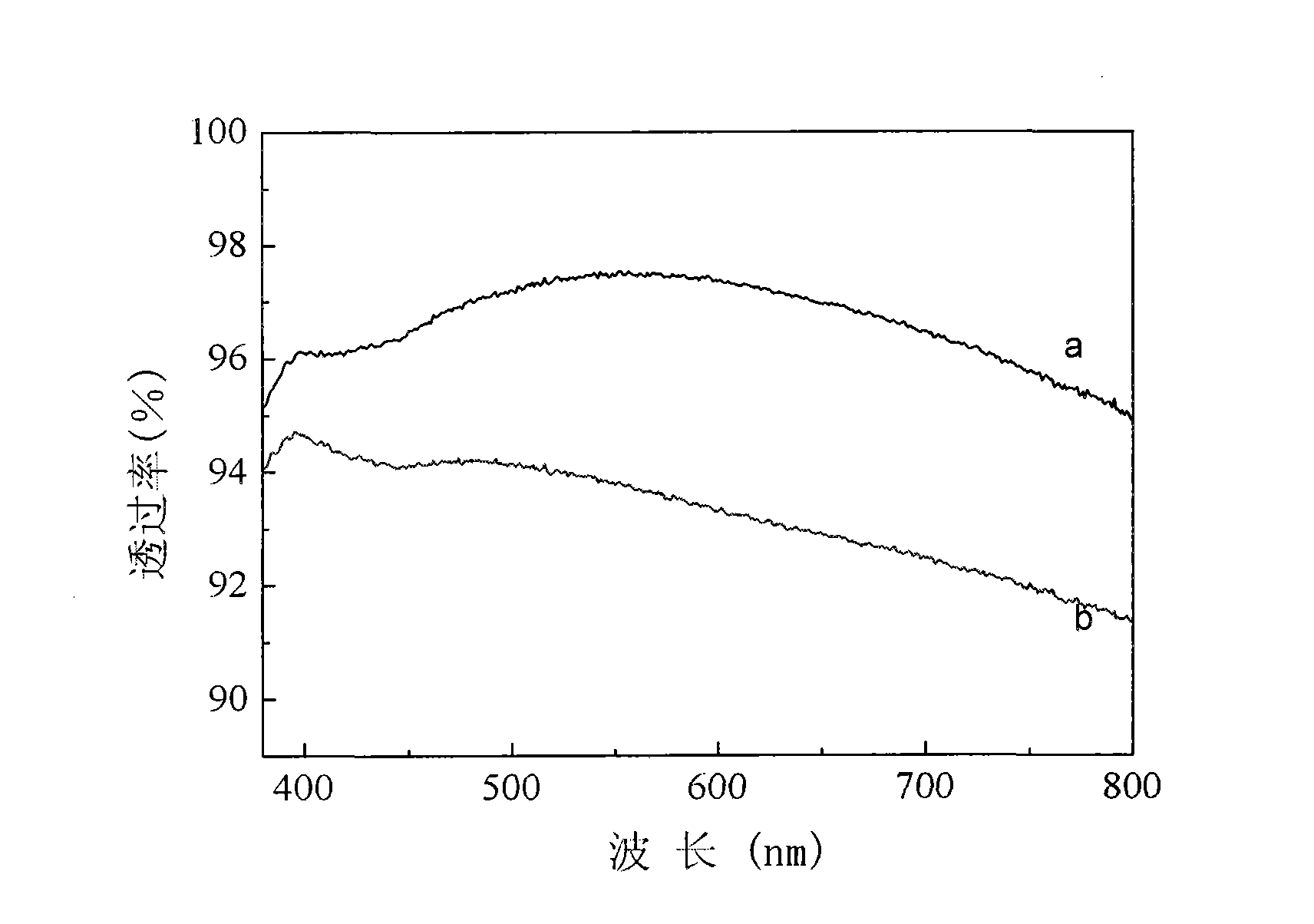

[0042] After the glass substrate is acid-washed, alkali-washed and dried, the transmittance of the white glass substrate in the visible light region is about 89%. A colloid containing magnesium-aluminum double hydroxide is prepared, and the colloid is composed of magnesium-aluminum double hydroxide powder and water, wherein the mass percentage of the magnesium-aluminum double hydroxide is 0.082wt%. Prepare silica-containing colloid by diluting commercially available silica sol with deionized water, wherein the mass percentage of silica is: 0.028wt%. At room temperature and normal pressure, first immerse a white glass sheet with a length of 76.2mm, a width of 25.4mm, and a thickness of 1mm in the colloid containing magnesium aluminum double hydroxide for 10 minutes, then rinse it with deionized water for 5 minutes, and then immerse it 15 minutes in colloidal silica, this is one layer. Repeat 4 times in turn to make it reach 4 layers. After drying, the transmittance was measur...

Embodiment 2

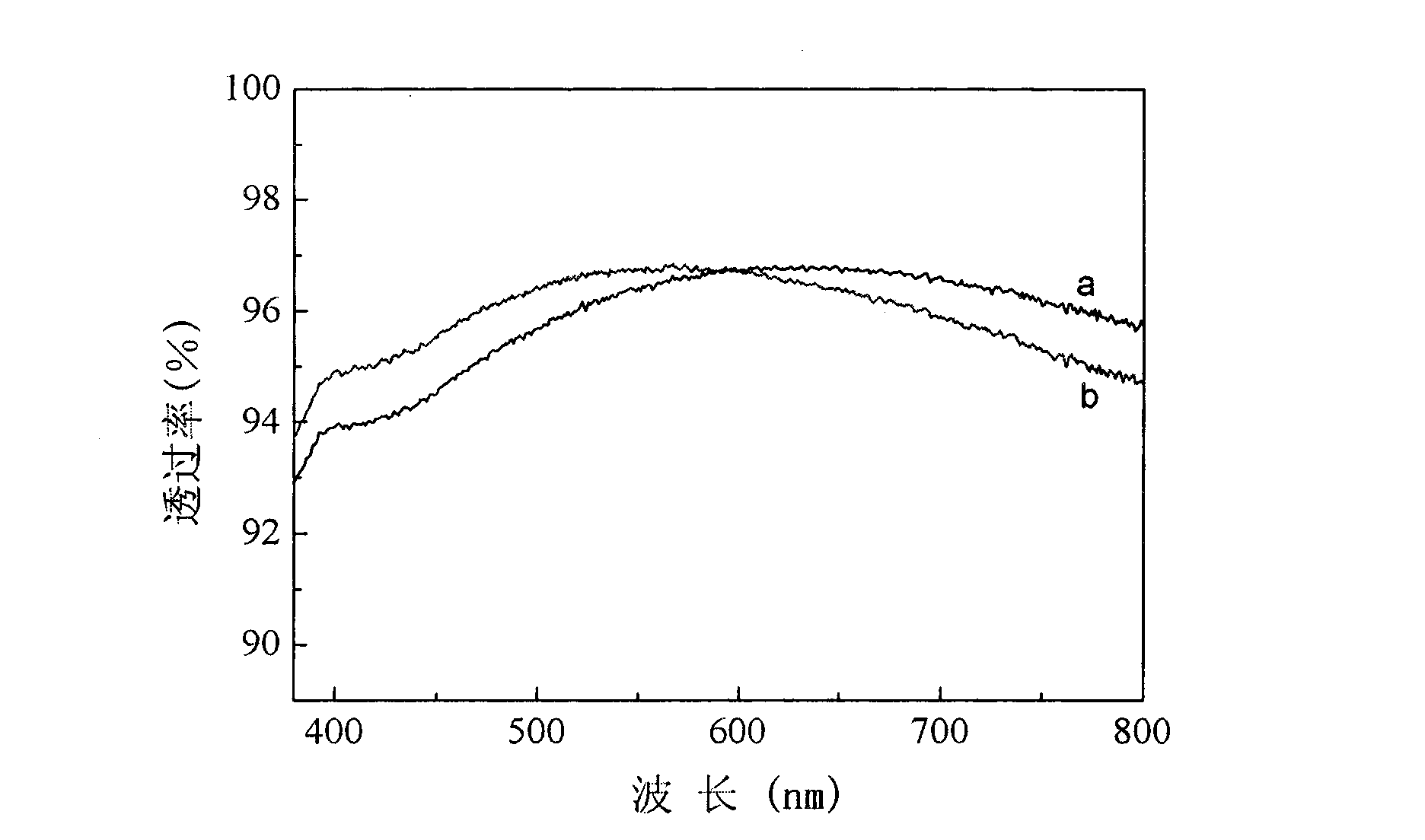

[0045] After the glass substrate was pickled and dried, the visible light transmittance of the glass substrate was 89%. At room temperature and normal pressure, first immerse a glass sheet with a length of 76.2mm, a width of 25.4mm, and a thickness of 1mm in the colloid containing magnesium aluminum double hydroxide for 20 minutes, then rinse it with deionized water for 5 minutes, dry it, and then Immerse in the colloid of titanium dioxide for 10 minutes, then rinse with deionized water for 5 minutes, and dry it as a layer. Repeat 8 times in order to make it reach 8 layers. The titanium dioxide colloid is self-made, wherein the titanium dioxide is an anatase phase, the grain size is about 7nm, and the mass percentage of the titanium dioxide is 0.053wt%. The magnesium aluminum carbonate double hydroxide colloid is prepared by ultrasonic dispersion of magnesium aluminum carbonate double hydroxide powder and water, wherein the mass percentage of the magnesium aluminum carbonate ...

Embodiment 3

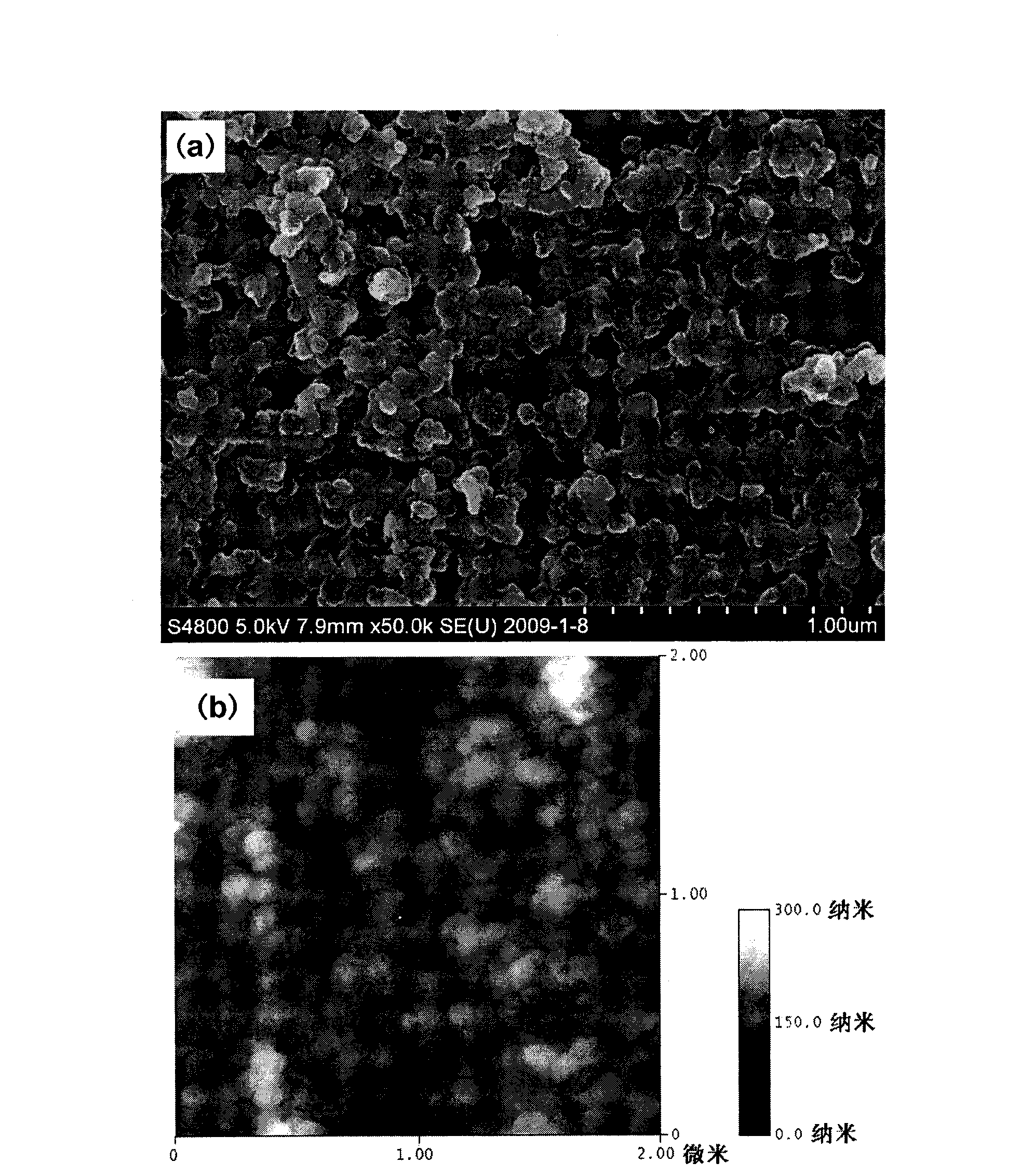

[0048] After the glass substrate is acid-washed, alkali-washed and dried, the transmittance of the white glass substrate in the visible light region is about 89%. A colloid containing magnesium-aluminum double hydroxide is prepared, and the colloid is composed of magnesium-aluminum double hydroxide powder and water, wherein the mass percentage of the magnesium-aluminum double hydroxide is 0.082wt%. Prepare silica-containing colloid by diluting commercially available silica sol with deionized water, wherein the mass percentage of silica is: 0.028wt%. At room temperature and normal pressure, first immerse a white glass sheet with a length of 76.2mm, a width of 25.4mm, and a thickness of 1mm in the colloid containing magnesium aluminum double hydroxide for 10 minutes, then rinse it with deionized water for 5 minutes, and then immerse it 15 minutes in colloidal silica, this is one layer. Repeat 4 times in order to make it reach 4 layers, counted as glass / (magnesium aluminum carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com