Light wave conversion-antireflection difunctional sol material and preparation method of thin film thereof

A light wave conversion and anti-reflection technology, which is applied in the field of optical materials, can solve the problems that cannot meet the high-temperature tempering process of photovoltaic glass, and achieve the effects of improving the utilization rate of sunlight, expanding the range of anti-reflection, and increasing the equivalent refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

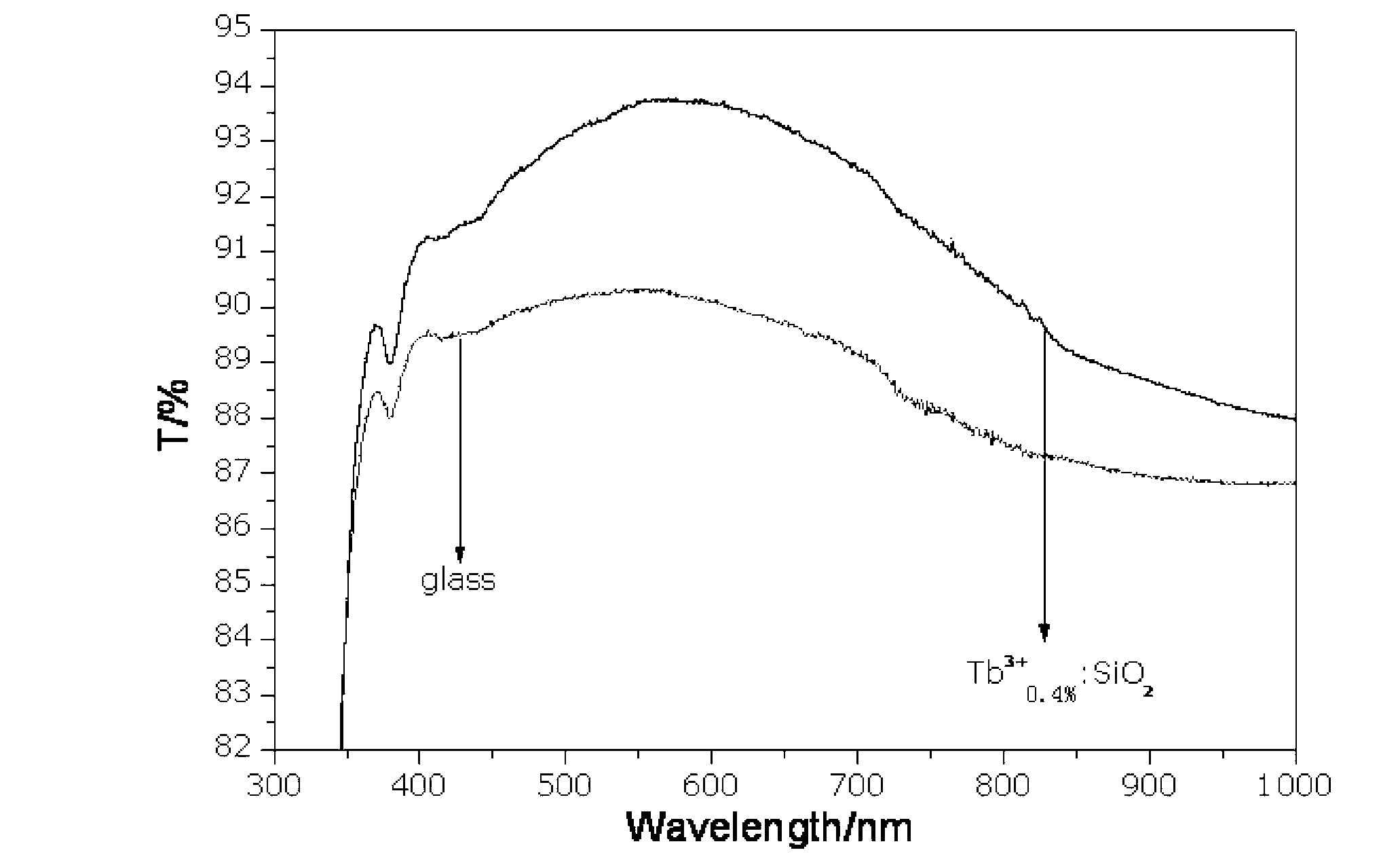

[0042] This example prepares Tb 3+ 0.4%: SiO 2 Sol material, the specific preparation process is as follows:

[0043] 1) At room temperature, mix one of the two equal parts of absolute ethanol with tetraethyl orthosilicate to obtain solution A, and stir the other part of absolute ethanol with deionized water for 30 minutes to obtain solution B; then mix the solution Mix A with solution B, adjust the pH value to 2-3 with concentrated hydrochloric acid, and stir at room temperature for 1 hour to obtain a mixed solution;

[0044] 2) Add Tb(NO 3 ) 3 ·6H 2 O, stirred at room temperature for 4 hours, left to age for 24h to obtain Tb 3+ 0.4%: SiO 2 Lightwave conversion-anti-reflection dual-functional sol material.

[0045] Wherein the mol ratio of ethyl orthosilicate, absolute ethanol total consumption, deionized water and terbium nitrate is: 1:15:4:0.4%, and the concrete consumption of each raw material is as follows:

[0046] Orthoethyl silicate (TEOS) 7.5ml,

[0047] Abso...

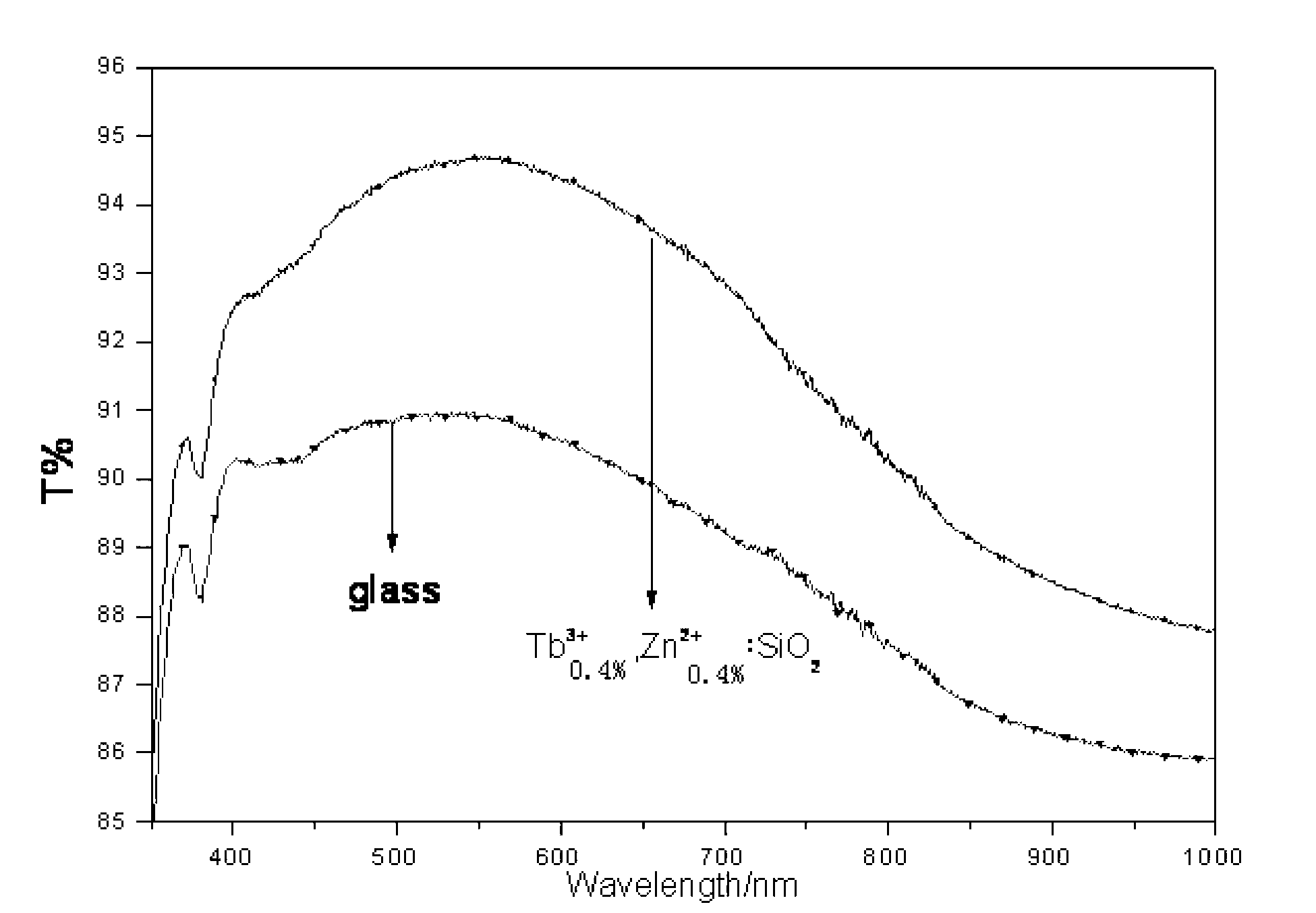

Embodiment 2

[0052] The difference between this example and Example 1 is that the molar ratio of the preparation raw materials is: ethyl orthosilicate: total amount of absolute ethanol: deionized water: terbium nitrate=1:20:4:0.4%. The specific consumption of each raw material is:

[0053] Tetraethyl orthosilicate 7.5ml,

[0054] Absolute ethanol 38.9ml,

[0055] Deionized water 2.4ml,

[0056] Tb(NO 3 ) 3 ·6H 2 O 0.06040g.

[0057] The aging temperature during the coating process is 20°C, the aging time is 5 days, and the pulling speed is 8cm / min. After natural drying at room temperature, it is annealed at 550°C for 2 hours to obtain a 100nm thick film. The photoelectric conversion efficiency test results showed that the photoelectric conversion efficiency increased by 2.5% after annealing at 550°C compared with that before coating.

Embodiment 3

[0059] The difference between this example and Example 1 is that the molar ratio of the preparation raw materials is: ethyl orthosilicate: total amount of absolute ethanol: deionized water: terbium nitrate=1:20:4:0.2%. The specific consumption of each raw material is:

[0060] Tetraethyl orthosilicate 7.5ml,

[0061] Absolute ethanol 38.9ml,

[0062] Deionized water 2.4ml,

[0063] Tb(NO 3 ) 3 ·6H 2 O 0.02020g.

[0064] The aging temperature during the coating process was 20°C, the aging time was 5 days, and the pulling speed was 9cm / min. After natural drying at room temperature, it was annealed at 550°C for 2 hours to obtain a film with a thickness of 108nm. The photoelectric conversion efficiency test results showed that the photoelectric conversion efficiency increased by 2.3% after annealing at 550°C compared with that before coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com