A method for improving the capacity of double-sided PERC battery plate type PECVD coating film

A battery panel, double-sided technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of not being able to improve the production capacity of the battery sheet, achieve the effect of improving the anti-reflection effect, improving the conversion efficiency, and widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

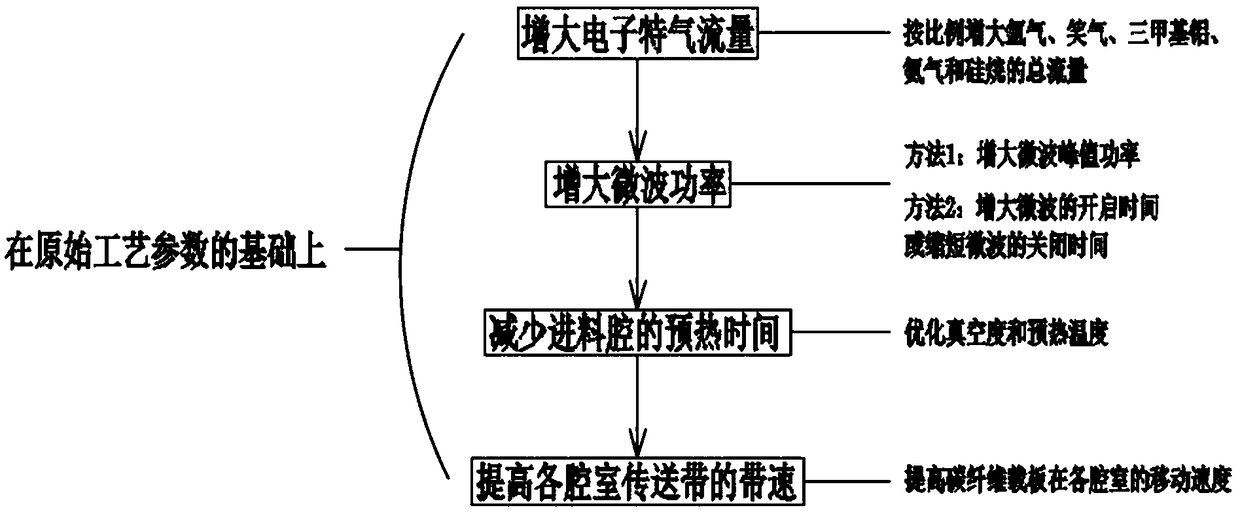

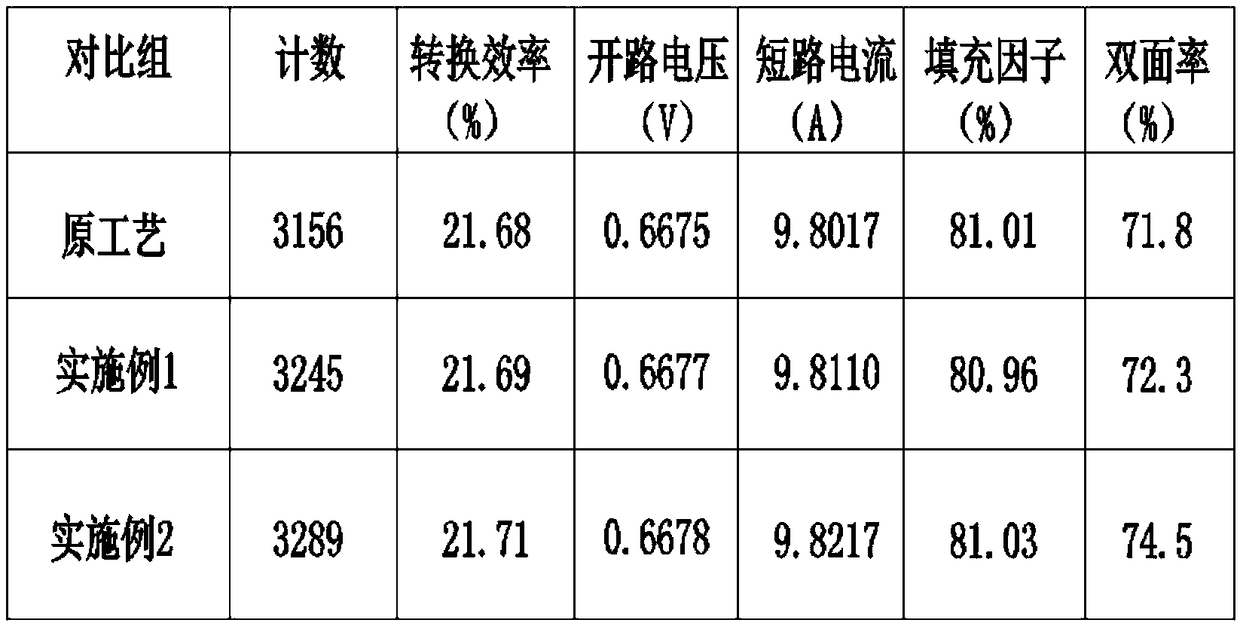

[0031] Embodiment 1: as figure 1 with figure 2As shown, a method is provided to improve the production capacity of double-sided PERC battery plate PECVD coating. The PM1 process chamber laughing gas flowmeter MFC1 is set to 550-650sccm, the trimethyl aluminum flowmeter is set to 450-550sccm, and the corresponding plasma source power is 2100 ~2300W, pulse on time 3~5ms, pulse off time 16~18ms; laughing gas flow meter MFC2 is set to 700~800sccm, the difference between MFC2 and MFC1 laughing gas flow is 150~200sccm, and the corresponding plasma source power is 2400~2600W, The pulse opening time is 5-7ms, and the pulse closing time is 16-18ms; the temperature of the process chamber is 340-370°C, and the pressure of the process chamber is 5×10-2mbar; the belt speed of the PM1 process chamber is set at 200-210cm / min. The ammonia flowmeters MFC1 to MFC5 in the PM2 process chamber are set to 800-900sccm, the silane flowmeters MFC1 to MFC5 are set to 300-400sccm, the corresponding pl...

Embodiment 2

[0033] Embodiment 2: as figure 1 with figure 2 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. The PM1 process chamber laughing gas flowmeter MFC1 is set to 550 ~650sccm, the trimethylaluminum flowmeter is set to 450~550sccm, the corresponding plasma source power is 2300~2500W, the pulse on time is 4~6ms, and the pulse off time is 16~18ms; the laughing gas flowmeter MFC2 is set to 700~800sccm, MFC2 The difference between the nitrous oxide flow rate and MFC1 is 150-200sccm, the corresponding plasma source power is 2400-2600W, the pulse opening time is 5-7ms, and the pulse closing time is 16-18ms; the process chamber temperature is 340-370°C, and the process chamber pressure is 5×10 -2mbar; PM1 process chamber belt speed is set to 205 ~ 210cm / min. The ammonia flowmeters MFC1 and MFC2 in the PM2 process chamber are set to 550-650sc...

Embodiment 3

[0035] Embodiment 3: as figure 1 with figure 2 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. The original process parameters refer to the equipment after entering the factory. , the original process parameters set by the supplier manufacturer, the specific process parameters are: PM1 process chamber laughing gas flowmeter MFC1 and MFC2 are set to 600~700sccm, trimethyl aluminum flowmeter is set to 450~550sccm, the corresponding plasma source The power is 2100-2300W, the pulse on time is 3-5ms, and the pulse off time is 16-18ms; the process chamber pressure is 5×10-2mbar, the process chamber temperature is 340-370°C, and the PM1 process chamber belt speed is set to 190-200cm / min. The ammonia gas flowmeters MFC1 to MFC5 in the PM2 process chamber are set to 600-800sccm, the corresponding plasma source power is 3200-3500W, the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com