Aluminum magnesium carbon sliding plate brick for stopping slag at steel tapping hole of converter

A tapping hole, aluminum-magnesium-carbon technology, applied in the field of converter refractories, can solve problems such as poor bonding strength, short service life, and insufficient compactness of the sliding brick structure, and achieve improved bonding strength, improved slag resistance, and improved slag retaining efficiency effect

Active Publication Date: 2011-11-23

ANSHAN CHOSUN REFRACTORIES

View PDF2 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide an aluminum-magnesium-carbon sliding brick for slag blocking at the taphole of a converter, which solves the problems of insufficient compactness, poor bonding

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

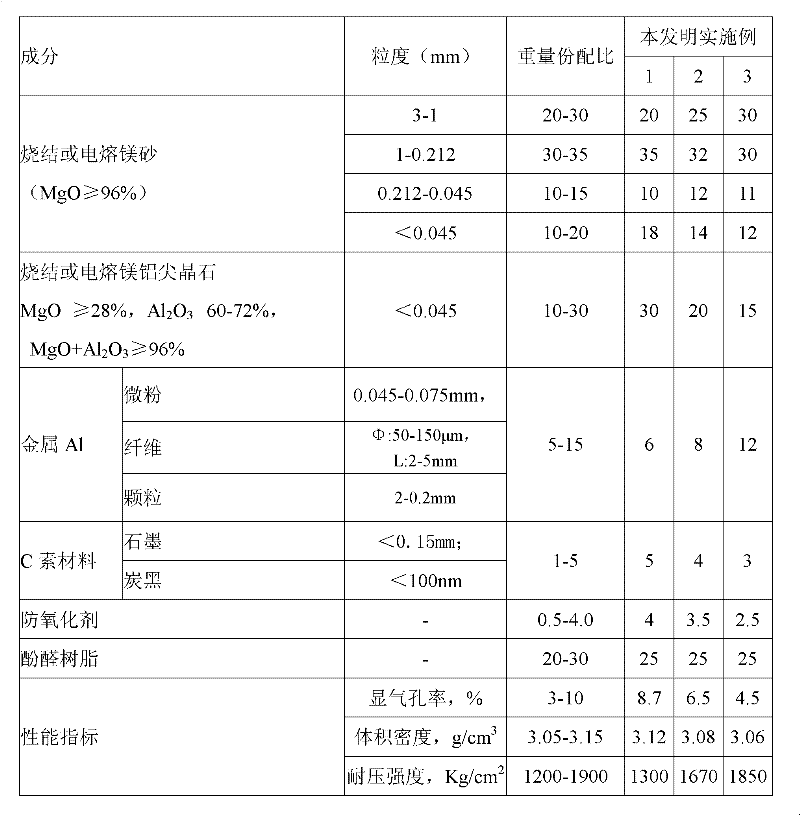

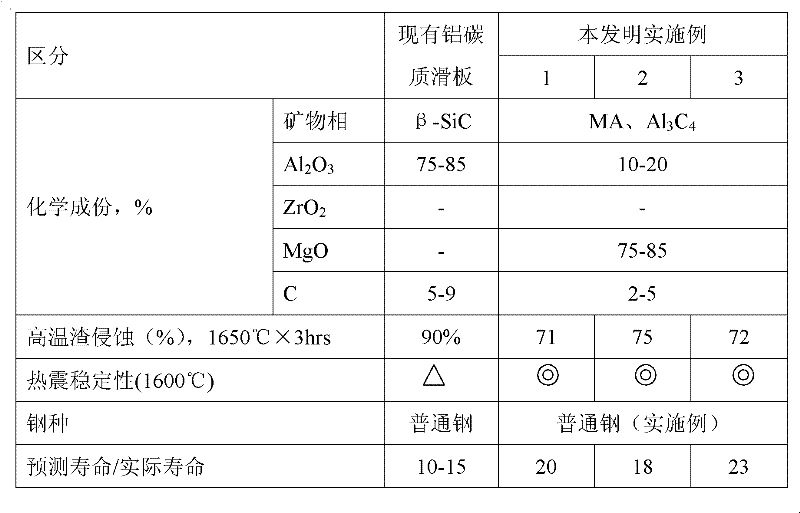

The invention relates to an aluminum magnesium carbon sliding plate brick for stopping slag at a steel tapping hole of a converter. The sliding plate brick is characterized by comprising the following components in parts by weight: 70-90 parts of sintered or electric smelting magnesia, 10-30 parts of sintered or electric smelting magnalium spinel, 5-15 parts of metal Al, 1-5 parts of carbon material, 0.5-4.0 parts of antioxidant and 20-30 parts of phenolic resin. Compared with the prior art, the sliding plate brick provided by the invention has the beneficial effects that the magnesia and magnalium spinel are introduced in a formula, thereby improving erosion resisting property and slag resisting property of the sliding plate and maintaining reasonable thermal shock stability; a network structure is formed by fusing and sintering the metal Al and carbonizing of the phenolic resin, thus the bonding strength of the sliding plate is greatly improved, the cracks of the sliding plate caused by thermal shock are reduced, the high-temperature comprehensive property of the sliding plate can be obviously improved, the service life of the sliding plate is prolonged, the reliable guarantee on quality products and use performance is provided for a technology of stopping slag at a sliding water gap of a converter, and the efficiency of stopping the slag of the converter is improved.

Description

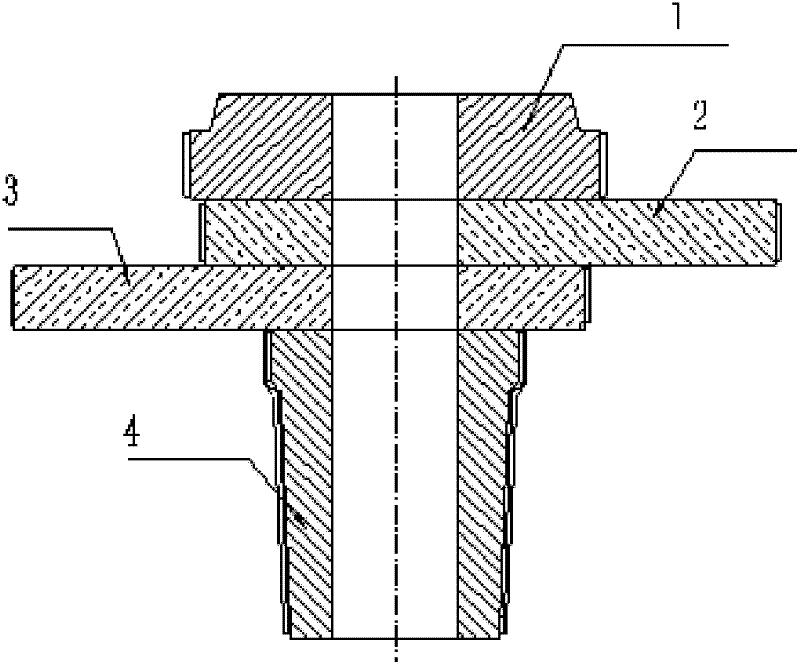

technical field [0001] The invention relates to the field of converter refractory materials, in particular to an aluminum-magnesium carbon sliding brick for slag blocking at a tap hole of a converter. Background technique [0002] At present, the development trend of converter tapping slag blocking technology at home and abroad is the sliding nozzle slag blocking technology with higher slag blocking efficiency. Its working principle is to slide the upper and lower plate bricks relative to each other through the sliding mechanism, so as to drive the opening and closing of the tapping hole to adjust the flow of molten steel, control the amount of steel slag entering the molten steel, and ensure the quality of molten steel. As an important functional part of the sliding nozzle system, the slide plate is required to have excellent high temperature strength, thermal shock stability, corrosion resistance and oxidation resistance in order to obtain a higher service life and a stabl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/66

Inventor 张小宁施岳明

Owner ANSHAN CHOSUN REFRACTORIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com