Micro-arc oxidation method for magnesium aluminum alloy and electrolyte

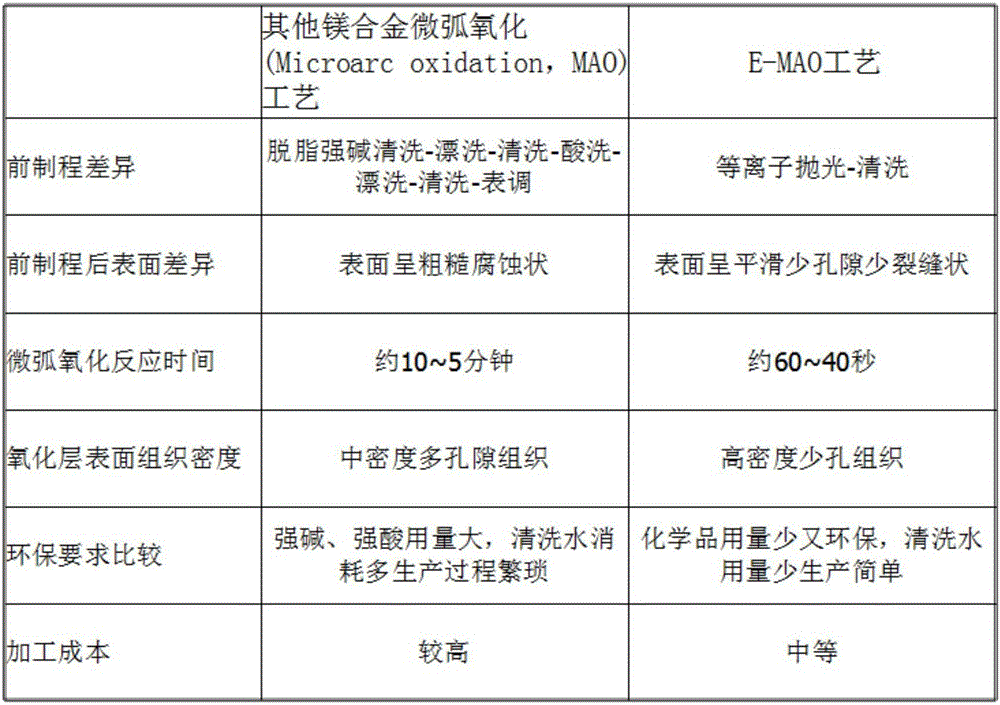

A micro-arc oxidation, magnesium-aluminum alloy technology, applied in the direction of anodizing, can solve the problems of uneven surface of magnesium alloy micro-arc oxidation film, poor corrosion resistance and wear resistance, environmental pollution, etc., to avoid strong acid and strong alkali The effect of using, smooth surface and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, a magnesium-aluminum alloy micro-arc oxidation method, the steps of the method are as follows:

[0026] S1. Plasma polishing: immerse the magnesium alloy object to be polished in the heated aqueous electrolyte solution, and apply a positive polarity voltage to it, and the applied voltage is a DC voltage;

[0027] S2, the first cleaning: put the polished magnesium alloy object into the cleaning tank for cleaning;

[0028] S3. Micro-arc oxidation: The magnesium alloy object cleaned for the first time is used as the anode of the electrolytic cell, and the stainless steel container is used as the cathode of the electrolytic cell, and the pulse current is used to perform micro-arc oxidation treatment on the magnesium alloy. The current density is constant, and the micro-arc oxidation process parameters are: : Current density 25mA / cm 2 , the positive and negative pulse duty ratios are 10%, the frequency is 400HZ, the power-on time is 40s, the electrolyte ...

Embodiment 2

[0036] In this embodiment, a magnesium-aluminum alloy micro-arc oxidation method, the steps of the method are as follows:

[0037] S1. Plasma polishing: immerse the magnesium alloy object to be polished in the heated aqueous electrolyte solution, and apply a positive polarity voltage to it, and the applied voltage is a DC voltage;

[0038] S2, the first cleaning: put the polished magnesium alloy object into the cleaning tank for cleaning;

[0039] S3. Micro-arc oxidation: The magnesium alloy object cleaned for the first time is used as the anode of the electrolytic cell, and the stainless steel container is used as the cathode of the electrolytic cell, and the pulse current is used to perform micro-arc oxidation treatment on the magnesium alloy. The current density is constant, and the micro-arc oxidation process parameters are: : Current density 35mA / cm 2 , the positive and negative pulse duty ratios are 25%, the frequency is 750HZ, the power-on time is 50s, the electrolyte ...

Embodiment 3

[0047] In this embodiment, a magnesium-aluminum alloy micro-arc oxidation method, the steps of the method are as follows:

[0048] S1. Plasma polishing: immerse the magnesium alloy object to be polished in the heated aqueous electrolyte solution, and apply a positive polarity voltage to it, and the applied voltage is a DC voltage;

[0049] S2, the first cleaning: put the polished magnesium alloy object into the cleaning tank for cleaning;

[0050] S3. Micro-arc oxidation: The magnesium alloy object cleaned for the first time is used as the anode of the electrolytic cell, and the stainless steel container is used as the cathode of the electrolytic cell, and the pulse current is used to perform micro-arc oxidation treatment on the magnesium alloy. The current density is constant, and the micro-arc oxidation process parameters are: : Current density 45mA / cm 2 , the positive and negative pulse duty cycle is 40%, the frequency is 1100HZ, the power-on time is 60s, the electrolyte t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com