Sand control pipe erosion rate experiment device

An experimental device, technology of sand control pipes, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of screen erosion rate based on experience, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

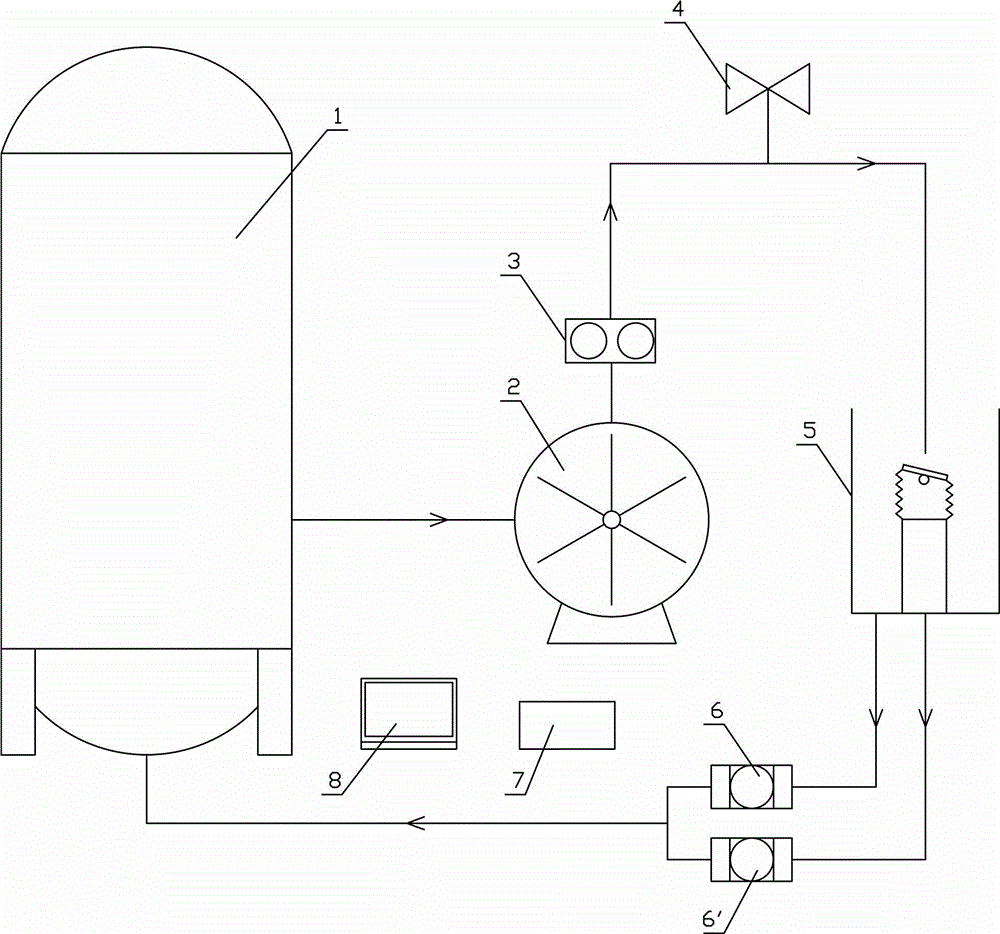

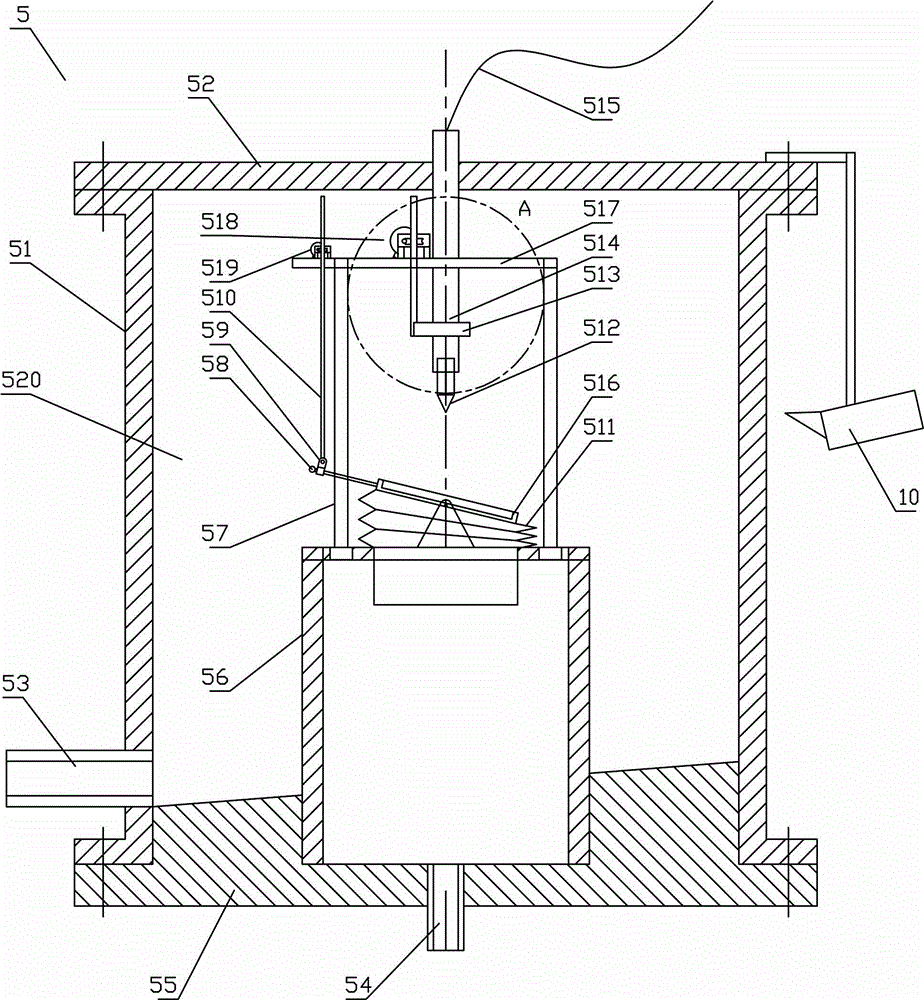

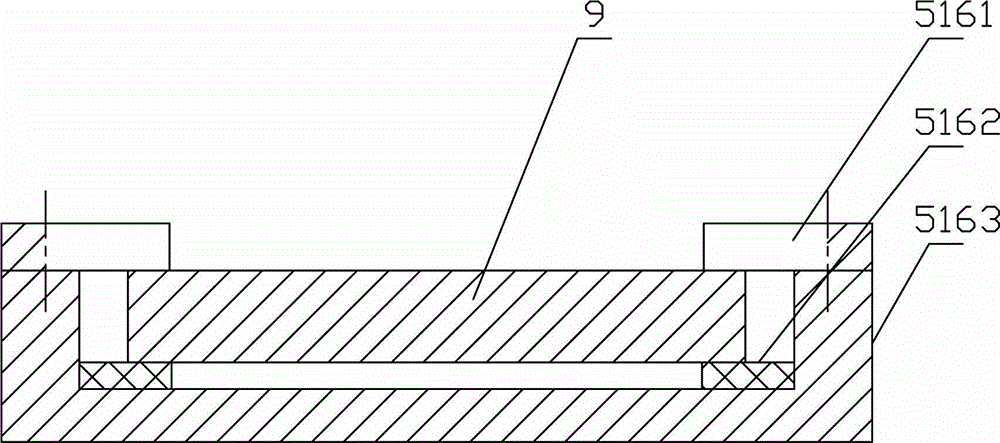

[0033] Such as figure 1 Among them, an experimental device for erosion rate of sand control pipes, the storage tank 1 is connected to the pump 2 through the pipeline, the pump 2 is connected to the erosion device 5 through the pipeline, the erosion device 5 is connected to the oil sand separation device through the pipeline, and the oil The sand separation device is connected to the storage tank 1; the storage tank 1 is used to uniformly mix the oil sand to form an erosion liquid. The erosion liquid in this example is the oil-sand mixture prepared according to the experimental requirements, mainly with a certain oil-sand volume ratio or oil-sand weight ratio for mixing, while the given sand grains are mainly mixed according to the grain size characteristics of the formation. Pump 2 is used to increase the pressure of the homogeneously mixed oil-sand mixture. The erosion device 5 is used to make the oil-sand mixture erode on the screen piece sample processed from the screen ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com