Automatic liquid level control method for crystallizer of large square bland continuous-casting machine

A liquid level control and crystallizer technology, applied in the field of metallurgical steelmaking, can solve the problems of inactive crystallizer liquid level, narrow slag line erosion range, poor surface quality of cast slabs, etc. speed, the effect of improving continuous pouring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

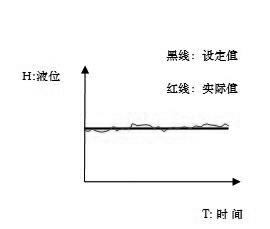

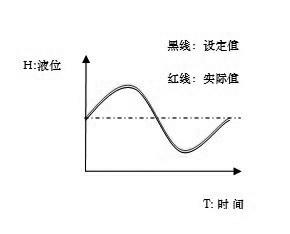

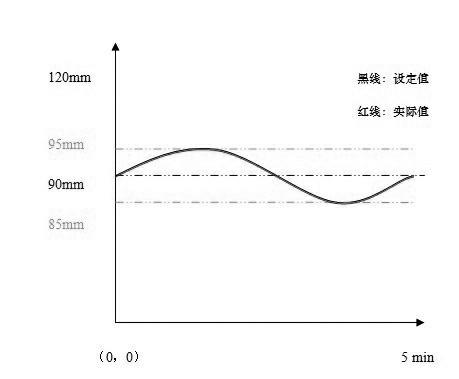

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: The section of the bloom continuous caster is 300mm×360mm, and the steel grade 40Cr is produced. The continuous casting process parameters are shown in the following table:

[0025]

[0026] During the process of pouring steel, observe the liquid level of the continuous casting mold. The liquid level of the 1-stream mold is not active, and the spreading of the mold powder is poor. The mold powder in the mold is thick in the middle (45mm) and thin on both sides (20mm). Measure the thickness of the liquid slag layer 8-10mm, mold slag consumption 0.40kg / t; 3-flow mold is active, mold slag spreads well, mold slag thickness is uniform (28~32mm), melting is uniform, measuring thickness of liquid slag layer is 8-10mm, protection The slag consumption is 0.43kg / t;

[0027] Measured at the watering stop, the width of the slag line of the 1 flow port is 12mm, and the width of the slag line of the 3 flow port is 25mm; the remaining thickness of the slag line of the 1 flow por...

Embodiment 2

[0029] Example 2: The section of the bloom continuous caster is 300mm×360mm, and the steel grade 20CrMnTi is produced. The continuous casting process parameters are shown in the following table:

[0030]

[0031] During the process of pouring steel, observe the liquid level of the continuous casting mold. The liquid level of the 1-stream mold is active, the mold slag spreads well, the mold slag thickness is uniform (30~34mm), and the melting is uniform. The thickness of the liquid slag layer is measured to be 8-10mm for protection. The slag consumption is 0.45kg / t; the liquid level of the 3-stream crystallizer is not active, and the spreading of the mold powder is poor. The mold powder in the mold is thick (48mm) in the middle and thin on both sides (23mm). The thickness of the measured liquid slag layer is 8-10mm, protecting The slag consumption is 0.48kg / t;

[0032] Measured at the watering stop, the width of the slag line of the 1 flow port is 26mm, and the width of the slag lin...

Embodiment 3

[0034] Example 3: The section of the bloom continuous caster is 300mm×360mm, and the steel grade GCr15 is produced. The continuous casting process parameters are shown in the following table:

[0035]

[0036] During the process of pouring steel, observe the liquid level of the continuous casting mold. The liquid level of the 1-stream mold is active, the mold slag spreads well, the mold slag thickness is uniform (32~37mm), and the melting is uniform. The thickness of the liquid slag layer is measured to be 9-11mm, protection The slag consumption is 0.25kg / t; the liquid level of the 3-stream crystallizer is not active, and the spreading of the mold powder is poor. The mold powder in the mold is thick in the middle (52mm) and thin on both sides (29mm). The thickness of the measured liquid slag layer is 9-11mm, protecting Slag consumption is 0.23kg / t;

[0037] Measured at the water stop, the width of the slag line at the 1 flow port is 28mm, and the width of the slag line at the 3 flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com