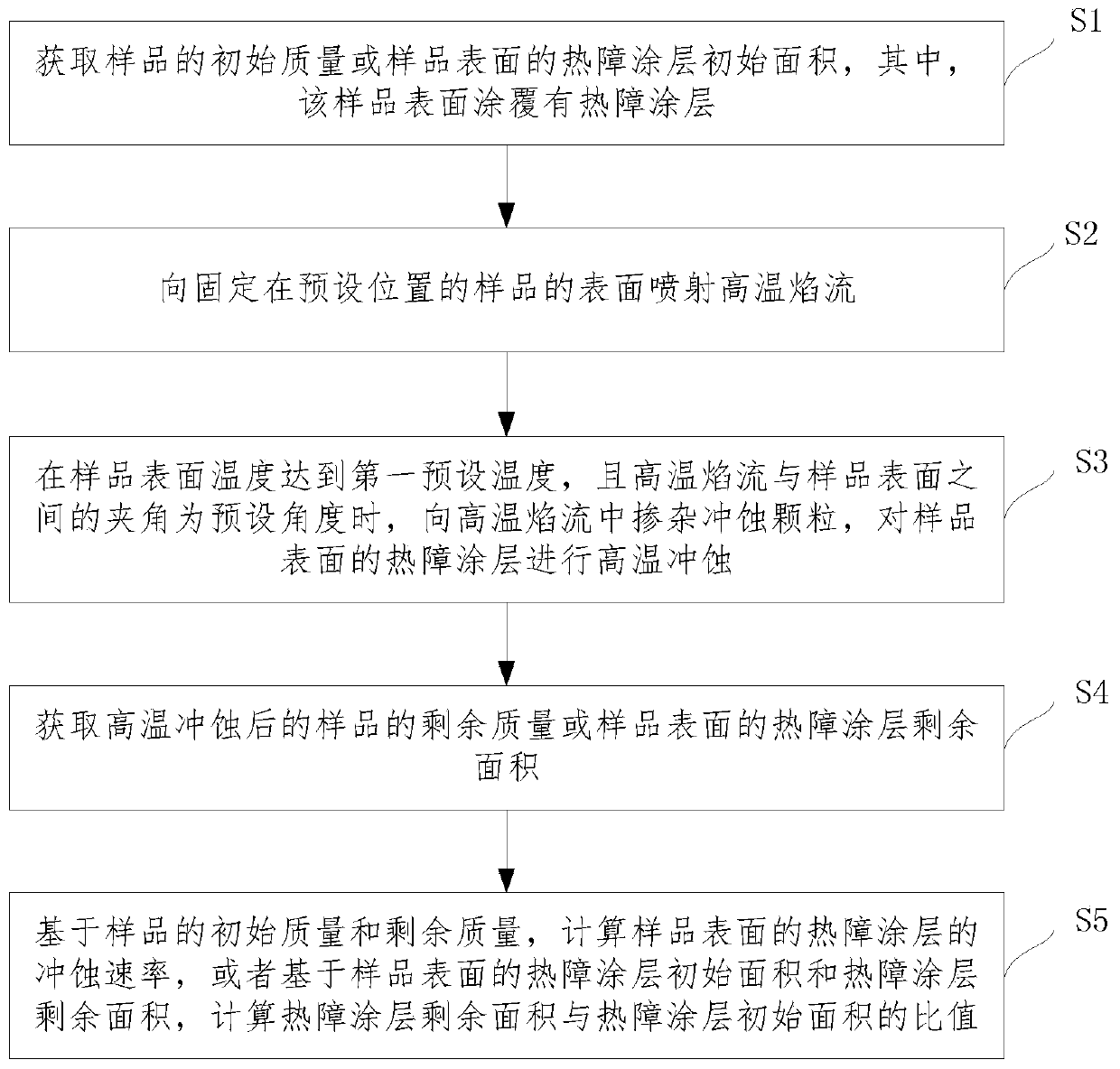

Thermal barrier coating high temperature erosion detection method

A thermal barrier coating and detection method technology, applied in the field of aero-engines, can solve problems such as difficult detection, low efficiency, and high cost, and achieve scientific and reasonable evaluation, improve detection efficiency, and save detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] image 3 It is a schematic diagram of the change of the surface morphology of the test piece level sample with the erosion time provided by Example 1 of the present invention.

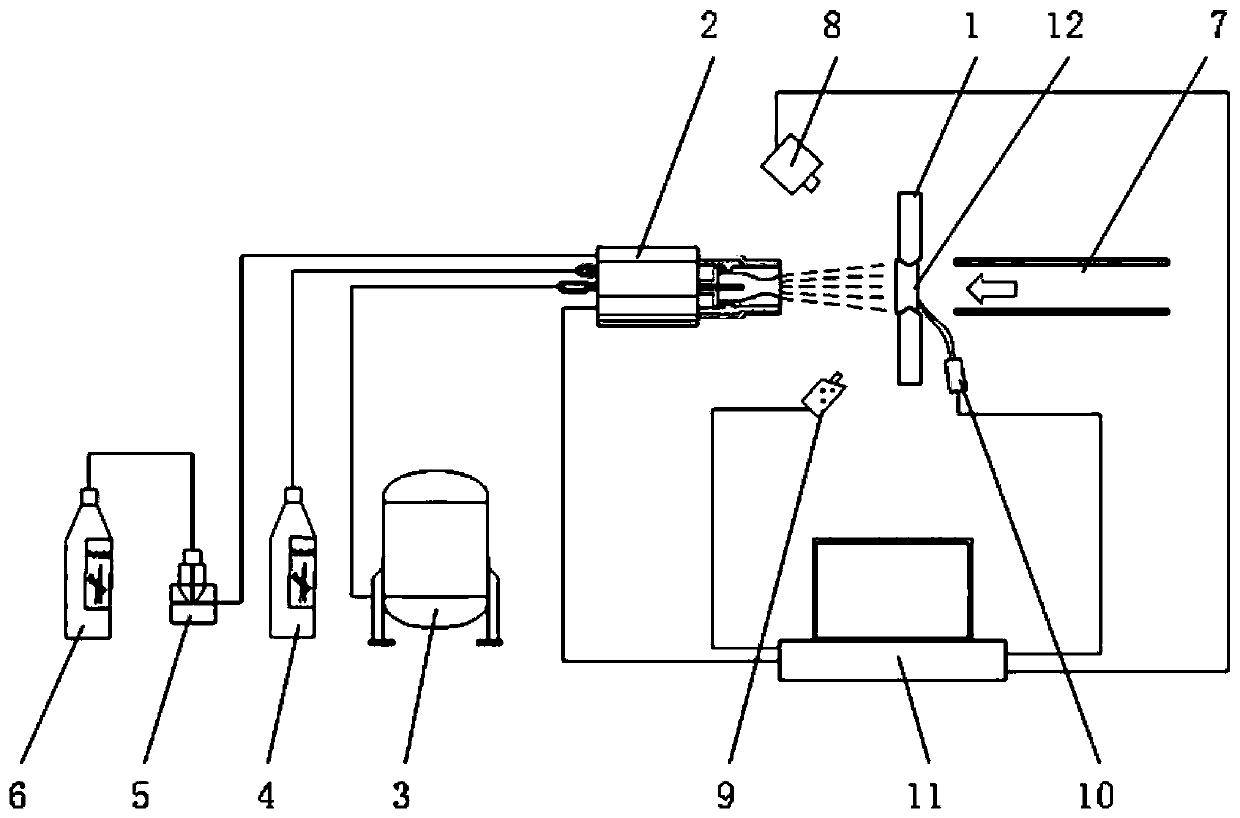

[0111] In this example 1, sample 12 is a test piece-level sample, clamped and fixed at a preset position by clamp 1, kerosene is pressurized to 0.6Mpa by N2, and then the kerosene is atomized by a liquid atomization device to form atomization Kerosene; O with a certain pressure and flow 2 Mix with atomized kerosene to form a fuel gas source, wherein the flow rate of atomized kerosene is 3.0L / h, O 2 The flow rate is 130L / min, O 2 The pressure is 1.05Mpa, O 2 The pressure is 0.2 MPa higher than the pressure of atomized kerosene; adjust the distance between the supersonic spray gun 2 and the sample 12, adjust the angle between the supersonic spray gun 2 and the sample surface to be 90°, and when the sample surface temperature reaches 1100 °C, pass The powder feeder 5 adds Al with a diameter of ...

Embodiment 2

[0114] Figure 4 It is a schematic diagram of the change curve of the erosion rate of the thermal barrier coating on the surface of the test piece-level sample provided by Example 2 of the present invention at different erosion angles with erosion time.

[0115] Please refer to Figure 4 , Figure 4 is a two-dimensional data point diagram based on the erosion rate and erosion time of the thermal barrier coating on the sample surface, where the abscissa is the erosion time and the ordinate is the erosion rate. The two-dimensional data point diagram reflects the change of the erosion rate with the erosion time of the test piece-level samples at different erosion angles.

[0116] The test conditions in this embodiment are when the erosion angles are 60°, 75° and 90° respectively, the average particle diameter of the erosion particles is 60 μm, and the transport rate of the erosion particles is 7 g / min. Perform high-temperature erosion, take multiple erosion time points during ...

Embodiment 3

[0128] Figure 5 It is a schematic diagram of the coating state of the thermal barrier coating on the surface of the blade-level sample during the high-temperature erosion test provided by Example 3 of the present invention.

[0129] Please refer to Figure 5 , the right side of the figure is the supersonic spray gun 2; the left side of the figure is the fixture 1 and the sample 12 installed on the fixture 1, wherein the sample 12 is a blade-level sample, and the black area on the left side of the figure is the heat insulation baffle; The white gas flow column between the sonic spray gun 2 and the sample 12 is the high-temperature flame flow generated by the supersonic spray gun 2 . It can be seen from the figure that due to the different degrees of high temperature erosion in each area of the leaf, on the one hand, the temperature of each area of the leaf is different, resulting in inconsistent colors on the surface of the leaf picture. The color of the area with higher ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com