Composite fireproof material and preparation method thereof

A technology of refractory materials and binders, applied in the field of refractory materials, can solve the problems of reduced service life, increased erosion rate, increased erosion rate, etc., and achieves the effects of improving service life, improving slag resistance, and meeting smelting requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method based on the composite refractory material provided by the invention comprises the following steps:

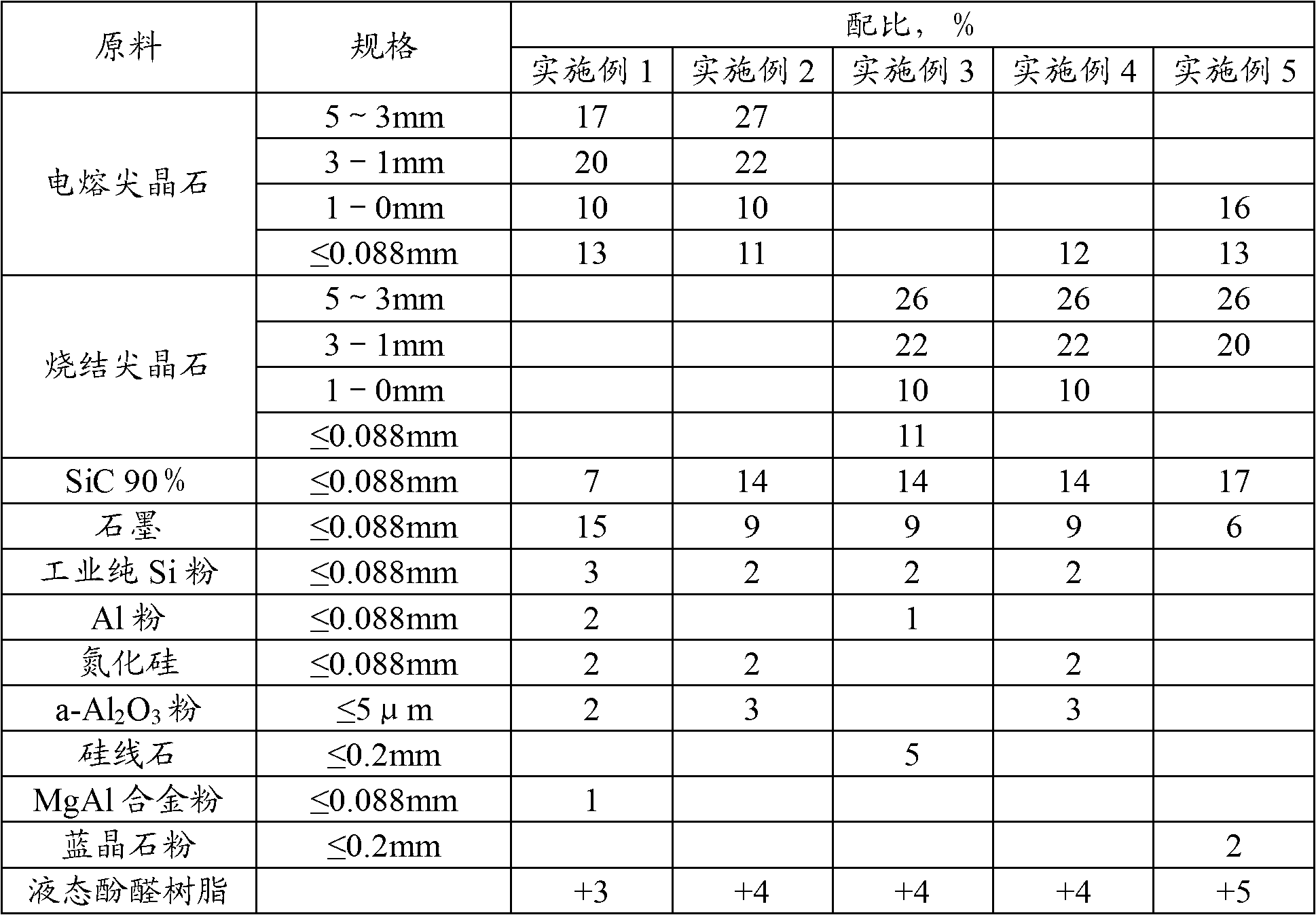

[0032] Step 1: Take fused or sintered magnesia-aluminum spinel according to mass percentage: 60-75%, silicon carbide: 5-17%, graphite: 5-15%, additive: 1-10%, plus the total amount of the above-mentioned components 3-5% resin binder by mass is mixed to form the first intermediate product;

[0033] Wherein, the mixing is achieved by mixing with a high-speed mixer for 45 minutes.

[0034] Step 2: forming the first intermediate product to form the second intermediate product;

[0035] Among them, the forming process is realized by using a 1000t friction brick press.

[0036] Step 3: heat-treating the second intermediate product to obtain a composite refractory material.

[0037] Wherein, the heat treatment takes 36 hours, and at the same time, the temperature is kept at a maximum temperature of 240° C. for 5 hours.

Embodiment 1

[0039] Referring to Table 1, the ingredients were prepared according to Example 1. After being mixed by a high-speed kneader for 45 minutes, it was formed by a 1000t friction brick press, and heat-treated for 36 hours at a maximum temperature of 240°C for 5 hours. 35MPa, the apparent porosity is less than or equal to 10%, and the bulk density is greater than 2.75g / cm 3 The composite refractory shaped product provided by the present invention.

Embodiment 2

[0041] Referring to Table 1, the ingredients were prepared according to Example 2. After being mixed by a high-speed kneader for 45 minutes, it was formed by a 1000t friction brick press, and heat-treated for 36 hours at a maximum temperature of 240°C for 5 hours. 35MPa, the apparent porosity is less than or equal to 10%, and the bulk density is greater than 2.75g / cm 3 The composite refractory shaped product provided by the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Normal temperature compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com