Electric furnace for expansive fireproof coating field detection and detecting method

A technology for fire-resistant coatings and on-site detection, which is applied in the direction of material thermal expansion coefficient, measuring device, specific gravity measurement, etc. It can solve the problems of making evaluations, requiring high professional experience of evaluation personnel, and difficult to make accurate distinctions, so as to reduce professional experience. Requirements, fast evaluation, and the effect of being easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

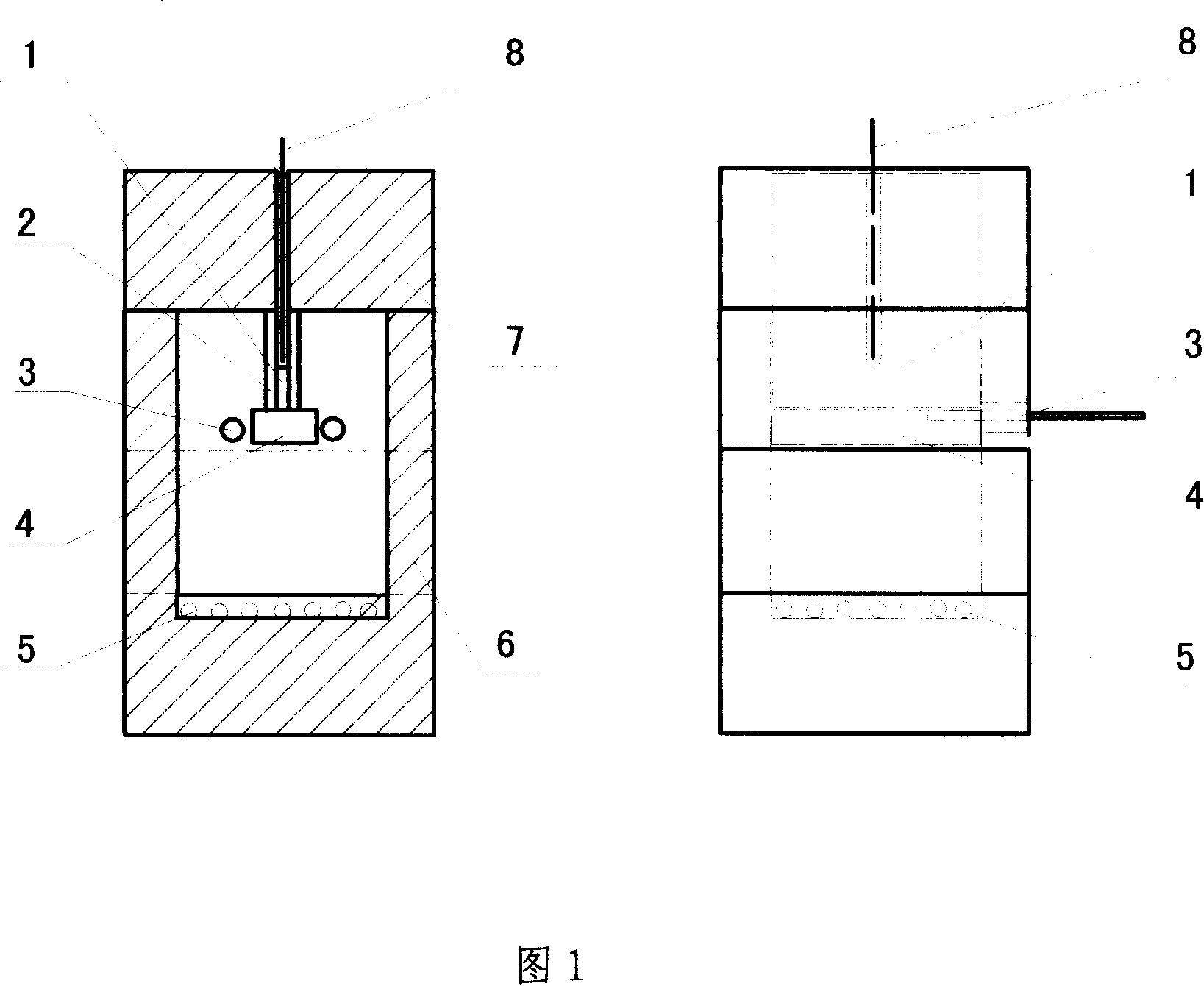

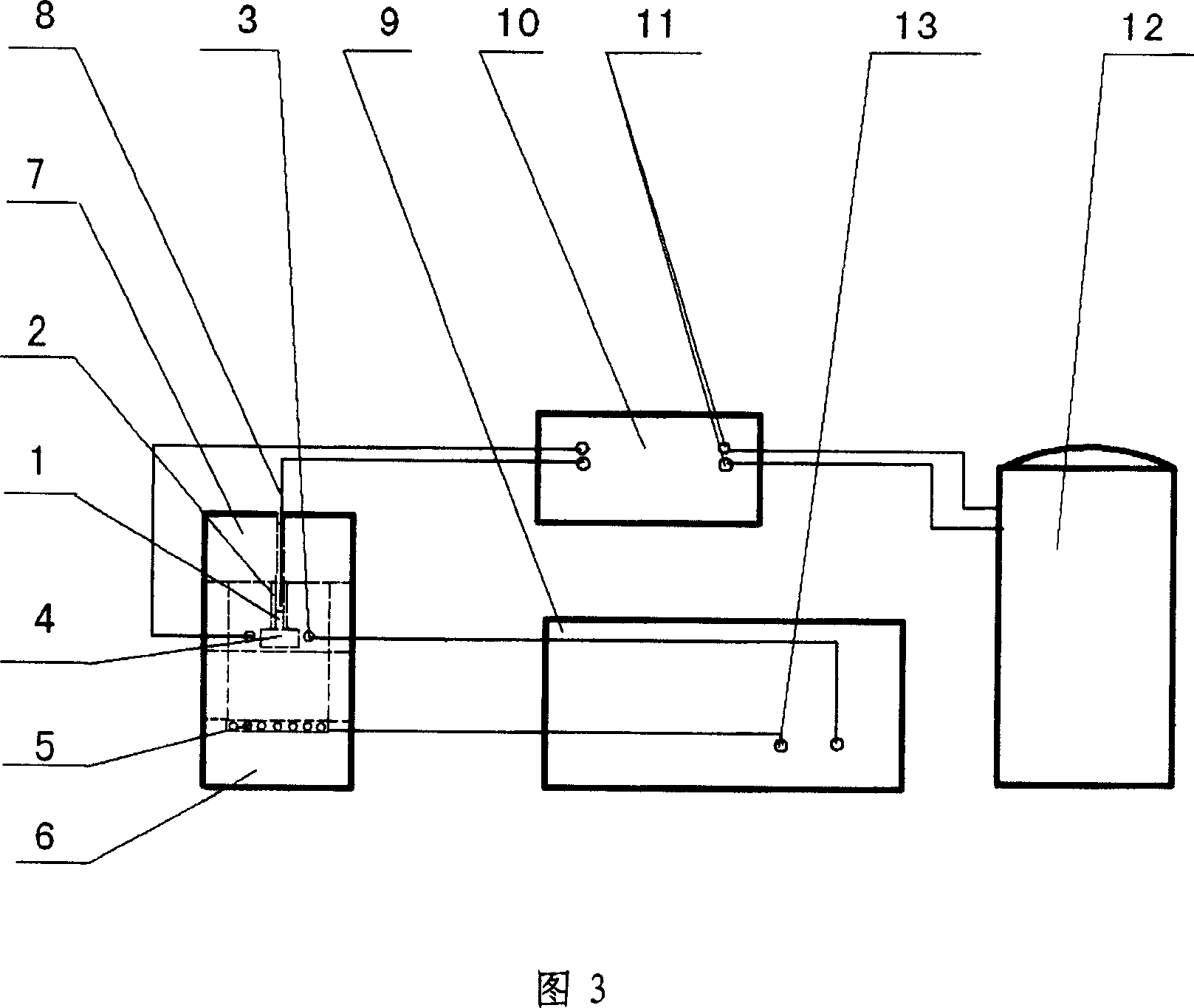

[0048] (1) The length A=230mm of body of furnace 6 inner cavity, width B=230mm;

[0049] (2) The width of the supporting brick 4 is 90mm, and the thickness is 65mm. Bracket 4 is placed on a heat-resistant metal bracket fixed on the furnace wall.

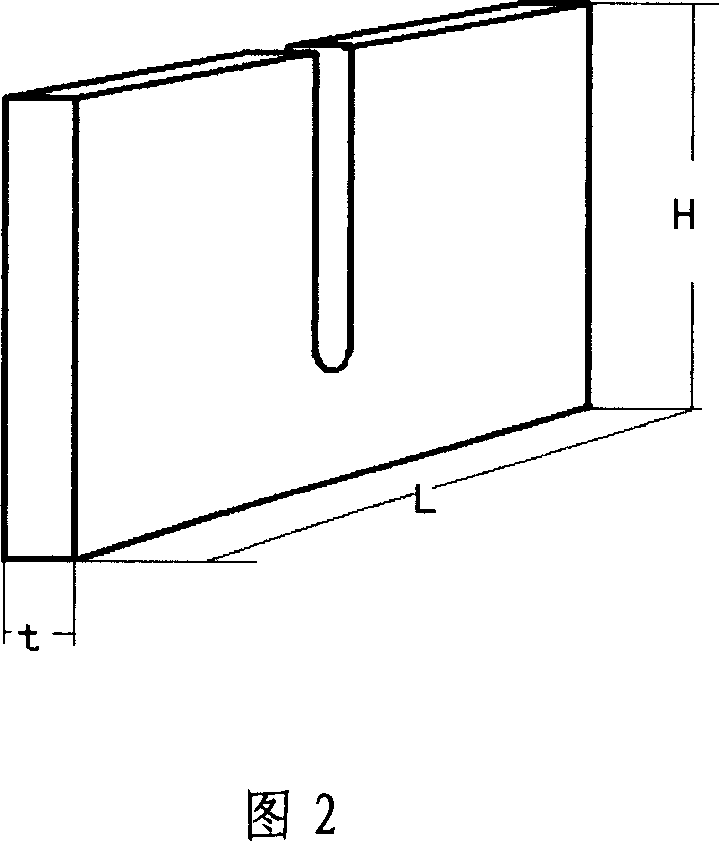

[0050] (3) The cooling chip 1 is made of ordinary carbon steel with an anti-oxidation layer, its length L=225mm, its height H=180mm, and its thickness t=8mm. The depth of the back temperature thermocouple installation groove 9 is 135mm.

[0051] (4) The furnace cover 7 is composed of two rectangular cover plates with a thickness of 230mm×115mm and a thickness of 65mm.

example 2

[0053] (1) The length A=150mm of furnace body 6 inner cavity, width B=150mm;

[0054] (2) The width of the supporting brick 4 is 60mm, and the thickness is 35mm. The length is 200mm, and both ends are inserted into the square holes in the side walls of the furnace.

[0055] (3) The cooling chip 1 is made of a black heat-resistant alloy with good oxidation resistance, its length L=147mm, its height H=120mm, and its thickness t=5mm. The depth of the back temperature thermocouple installation groove 9 is 90mm.

[0056] (4) The furnace cover 7 is composed of two rectangular cover plates with a thickness of 150mm×72mm and a thickness of 65mm.

example 3

[0058] (1) The length A=82mm of body of furnace 6 inner cavity, width B=82mm;

[0059] (2) The width of the supporting brick 4 is 20mm, and the thickness is 20mm. Bracket 4 is placed on a heat-resistant metal bracket fixed on the furnace wall.

[0060] (3) The cooling chip 1 is made of ordinary carbon steel with an anti-oxidation layer, its length L=80mm, its height H=80mm, and its thickness t=3mm. The depth of the back temperature thermocouple installation groove 9 is 60mm.

[0061] (4) The furnace cover 7 is composed of two rectangular cover plates with a size of 115×55mm and a thickness of 65mm.

[0062] The embodiment of test method of the present invention is as follows:

[0063] example 1,

[0064] Make test sample; Sample 2 length A=225mm, its height B=90mm, its thickness p=1.8mm, net weight 290g, 290g before coating fireproof coating, weight 373g, 375g after coating fireproof coating.

[0065] Measure the thickness of the coating; use a non-destructive testing thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com