Experimental device and representation method of multiphase medium high-temperature corrosion rate

An experimental device, high-temperature corrosion technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, weighing by removing certain components, etc., can solve the problem that the high temperature corrosion rate of metals cannot be accurately characterized, and the microscopic corrosion factors cannot be reflected. , can not intuitively represent problems such as high temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structural principle and working principle of the present invention will be described in more detail below in conjunction with the accompanying drawings.

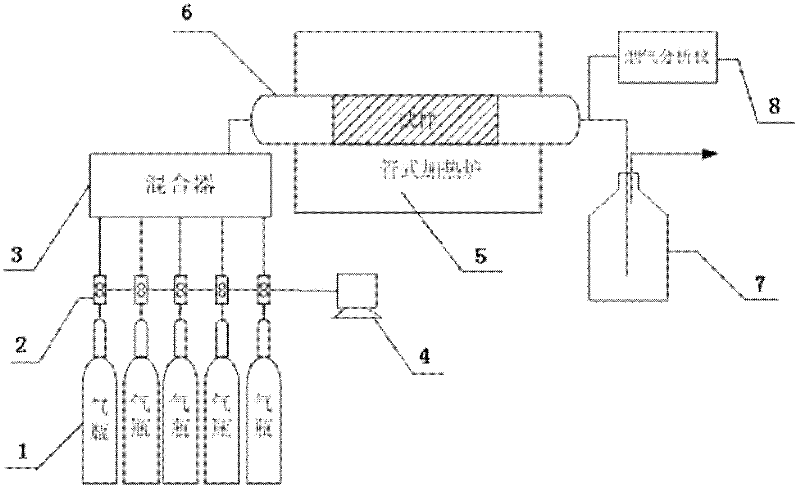

[0031] Such as figure 1 As shown, the present invention is a test device for the high-temperature corrosion rate of a multiphase medium, including a gas distribution device, a heating device connected to the gas distribution device, and an exhaust gas treatment device connected to the heating device, and the gas distribution device includes Mixer 3, at least two gas cylinders 1 communicated with the mixer 3; a mass flow meter 2 is arranged between the mixer 3 and each gas cylinder 1, and the mass flow meter 2 is connected with a computer 4, each The gas cylinder 1 is respectively filled with the gas N required for the experiment 2 , CO 2 , O 2 , H 2 S and SO 2 , each gas cylinder 1 is connected with a separate mass flow meter 2, and the mass flow meter 2 includes a gas mass controller and a gas mass flow met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com