Method for measuring contents of silicon-calcium elements in silicon-calcium alloy

A silicon-calcium alloy and element content technology, which is applied in the field of chemical element analysis and determination, can solve the problems of environmental and personal hazards, poor measurement accuracy, and cumbersome operation process, avoiding pollution, improving accuracy and precision, and analyzing methods. advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

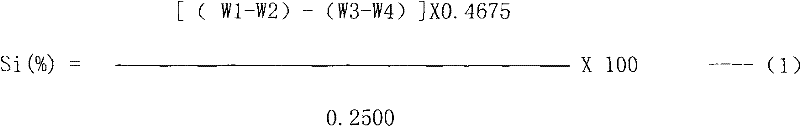

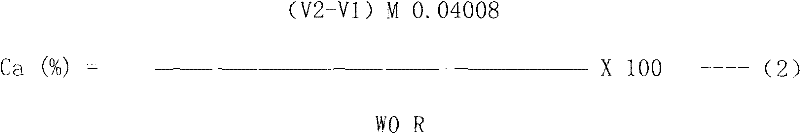

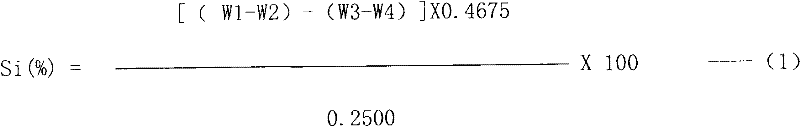

[0040] The assay method of silicon-calcium element content in a kind of silicon-calcium alloy of the present invention comprises the following steps:

[0041] 1. Experimental Preparation

[0042] The calcium-silicon alloy sample is ground by a sample preparation machine to pass through a 180-200 mesh analytical sieve.

[0043] 2. Use the alkali fusion method to melt the sample at high temperature, and use 2-6 grams of solid alkali as the solvent. The melting process is: weigh 0.1-0.5 grams of the sample and 2-6 grams of sodium hydroxide solid in a nickel crucible, Cover it, put it in a high-temperature furnace, heat it at a low temperature, and then slowly raise the temperature to 700 degrees to melt for 15 minutes, take it out, and cool it down. Wash the molten sample with deionized water and hydrochloric acid into an evaporating dish, heat and evaporate, dry, add hydrochloric acid to acidify, add warm water and stir until all soluble salts are completely dissolved, immediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com