Automatic test equipment for volatiles of bituminous coal

An automatic testing equipment and volatile technology, applied in the direction of removing certain components and weighing, etc., to achieve the effect of increasing scientificity, reducing labor intensity and manual errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

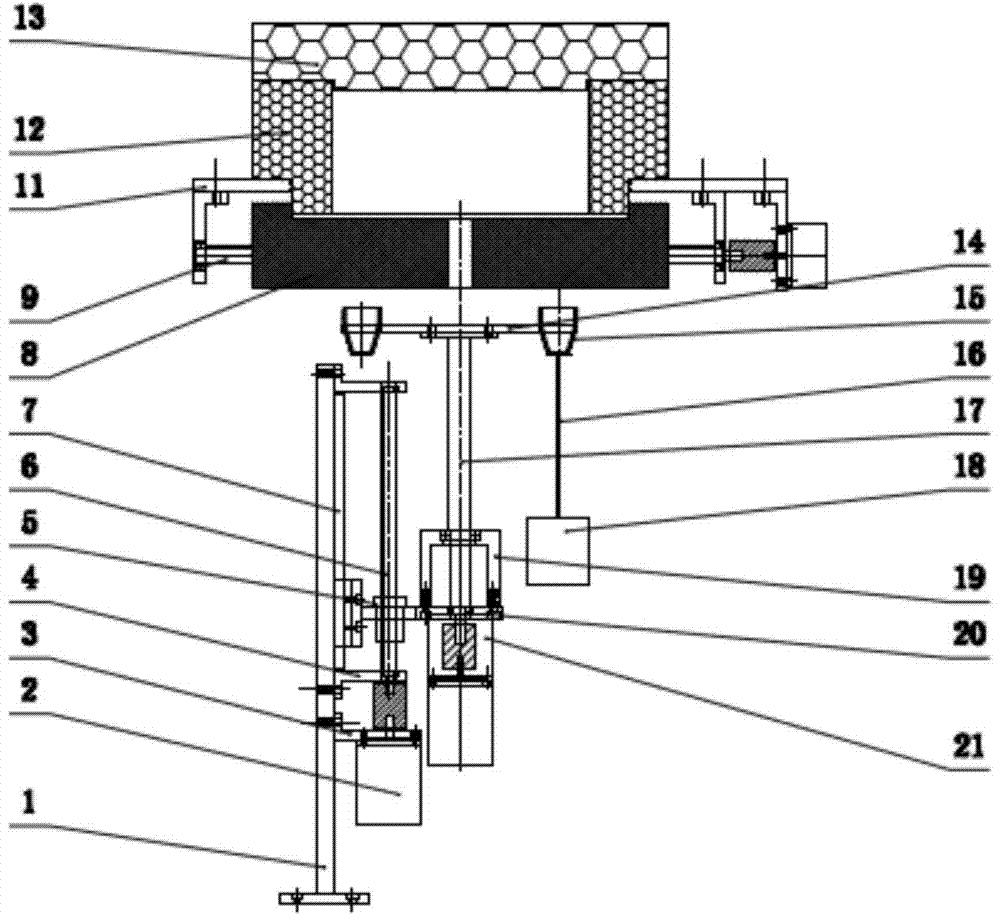

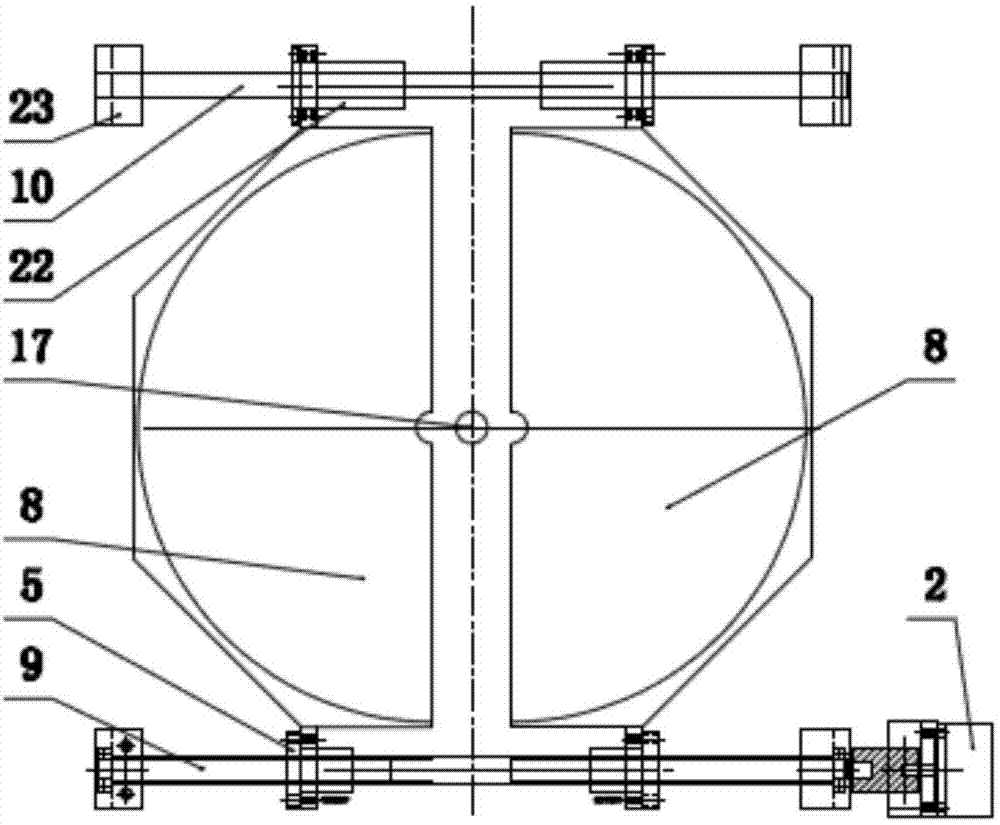

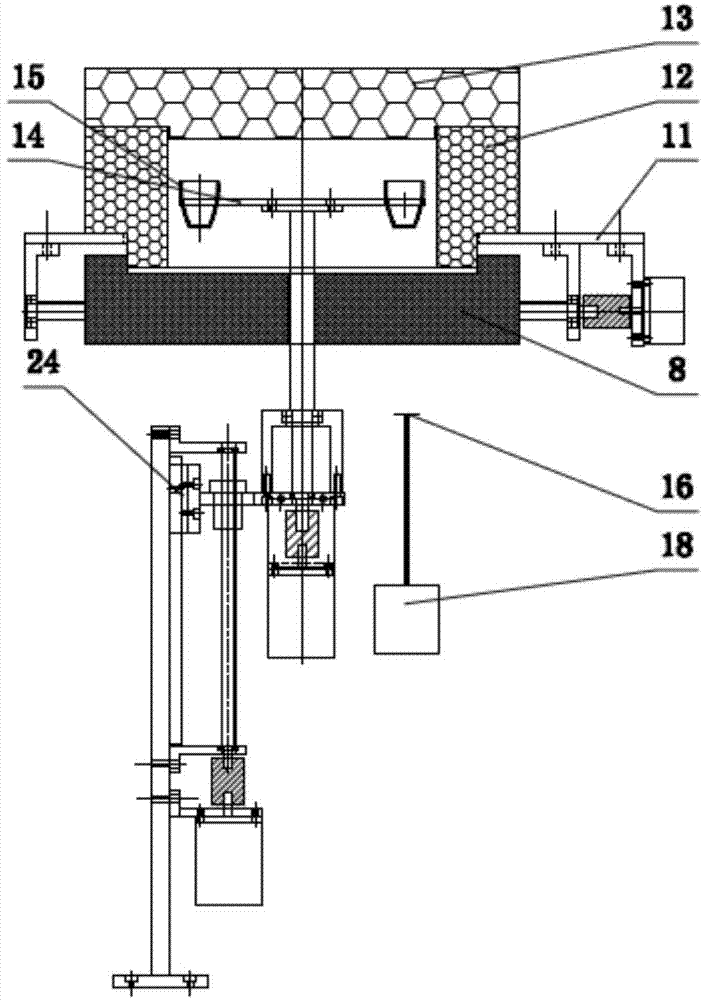

[0014] see figure 1 and image 3 As shown, the automatic test equipment for volatile content of bituminous coal includes a bituminous coal heating module and a bituminous coal weighing module. The furnace 12 with embedded resistance wire of the present invention, the furnace cover 13 installed above the furnace 12, and the two movable furnace doors 8 constitute the experimental environment for bituminous coal volatile matter (the temperature is about 900 ° C); 20 crucibles 15 are evenly placed The crucible plate 14 is located in the middle of the furnace 12.

[0015] see figure 1 and image 3 As shown, the bituminous coal weighing module of the present invention includes a T-shaped support 1, an L-shaped motor frame 3, an L-shaped bearing frame 4A, a linear guide rail 7, and an L-shaped bearing mounted on the right side of the T-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com