Gravitational thermal analysis method and device for heating sample by microwave

A technology of thermogravimetric analysis and microwave heating furnace, which is applied in the preparation of test samples and weighing by removing certain components, which can solve the problems of small sample usage, unsatisfactory heating methods, and small thermal conductivity. , to achieve the effect of convenient installation and maintenance, solving temperature measurement problems, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

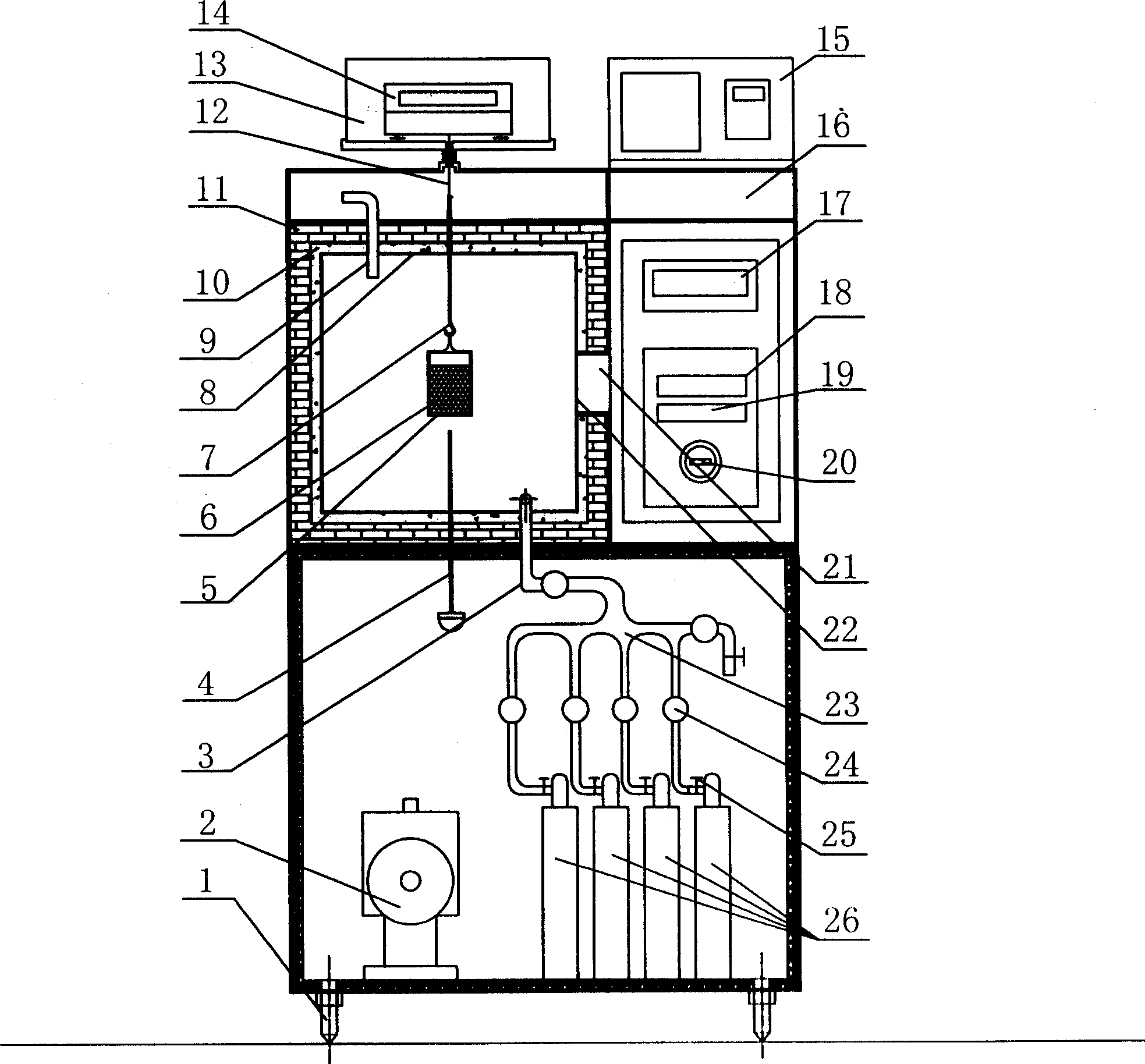

[0021] Embodiment 1: This method heats the sample with microwaves, and the microwave input power is continuously adjustable between 0-3KW. The microwave input power can be set to a fixed value, or it can be set to be linked with the temperature measurement system; The stainless steel wall is condensed, and a heating resistance wire is installed outside the stainless steel furnace wall to maintain the temperature of the stainless steel wall between 350-400°C. The quality of the sample is measured online with a mass sensor; the weighing range of the mass sensor is 0-300g, and the resolution is 0.01g. The position of the quartz hanging basket in the furnace can be realized by changing the length of the heat-resistant wire, and samples with a diameter of <40mm can be placed. The temperature of the sample is measured online with an infrared thermometer or a thermocouple; the heating atmosphere is an air atmosphere, and the required gas is stored in a gas cylinder 26 . Different ga...

Embodiment 2

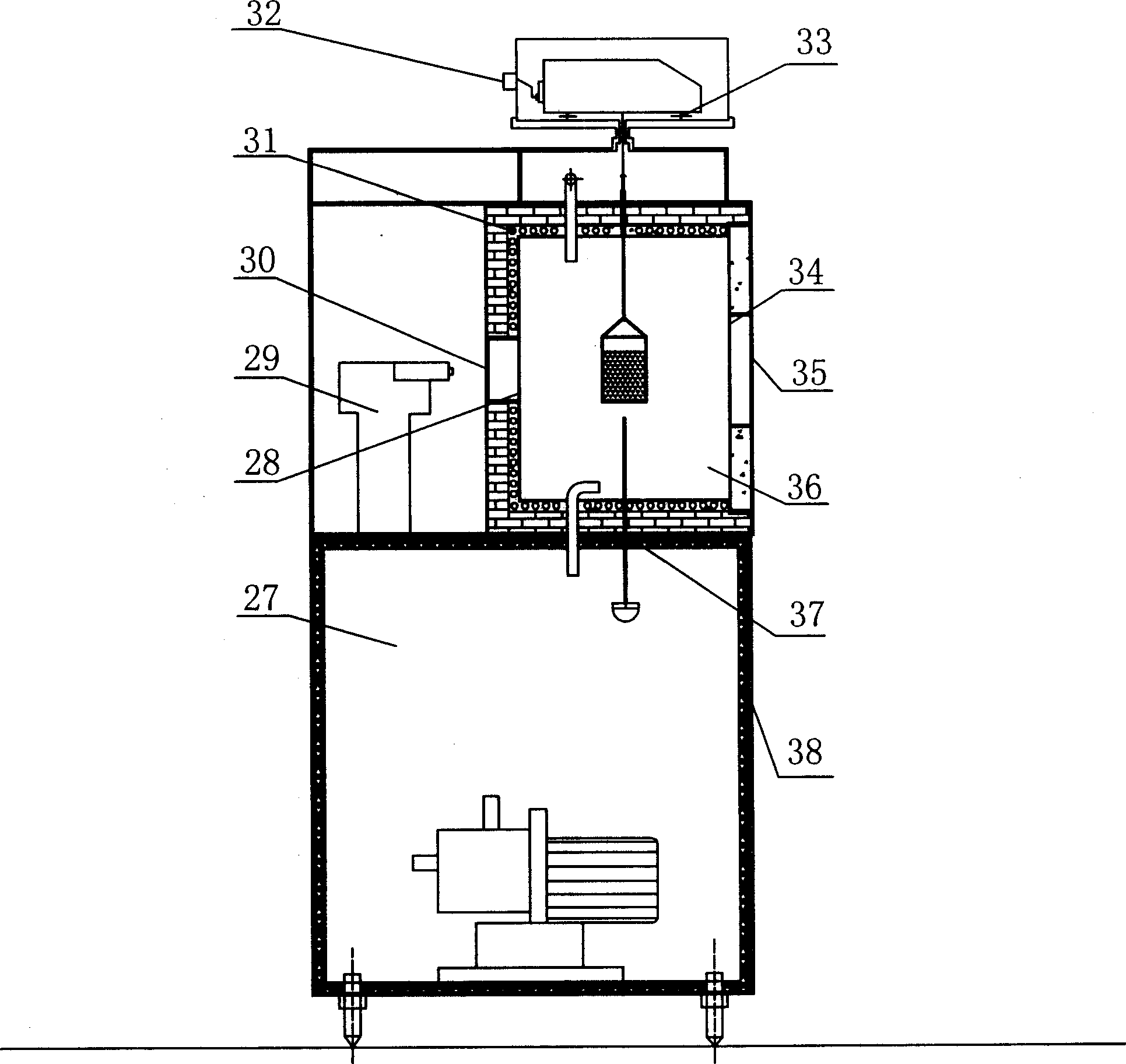

[0029] Embodiment 2: method and device are identical with embodiment 1, and difference is, carry out thermogravimetric analysis to different sample, need to adjust the heating atmosphere in furnace 36, be further explanation with heating atmosphere as oxygen atmosphere below: adjust oxygen cylinder Pipeline flowmeter 24 reaches the maximum opening, open the switch of oxygen cylinder 26, adjust the regulating valve 25 to the appropriate opening, flush the furnace for about 5 minutes, and after the air in the furnace is exhausted, adjust the regulating valve 25 so that the flowmeter 24 reads to The flow rate required for heating is sufficient, and the heating atmosphere is adjusted.

[0030] A thermocouple 4 is installed on the furnace wall at the lower part of the furnace 36 to measure the atmosphere temperature and display it through the atmosphere temperature display 18 . The heating atmosphere and flow in the furnace 36 are prepared and regulated through the air inlet 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com