Vibration test three-dimensional deformation measuring device based on laser speckle interference

A technology of vibration test and three-dimensional deformation, which is used in measurement devices, vibration tests, and optical devices to avoid measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

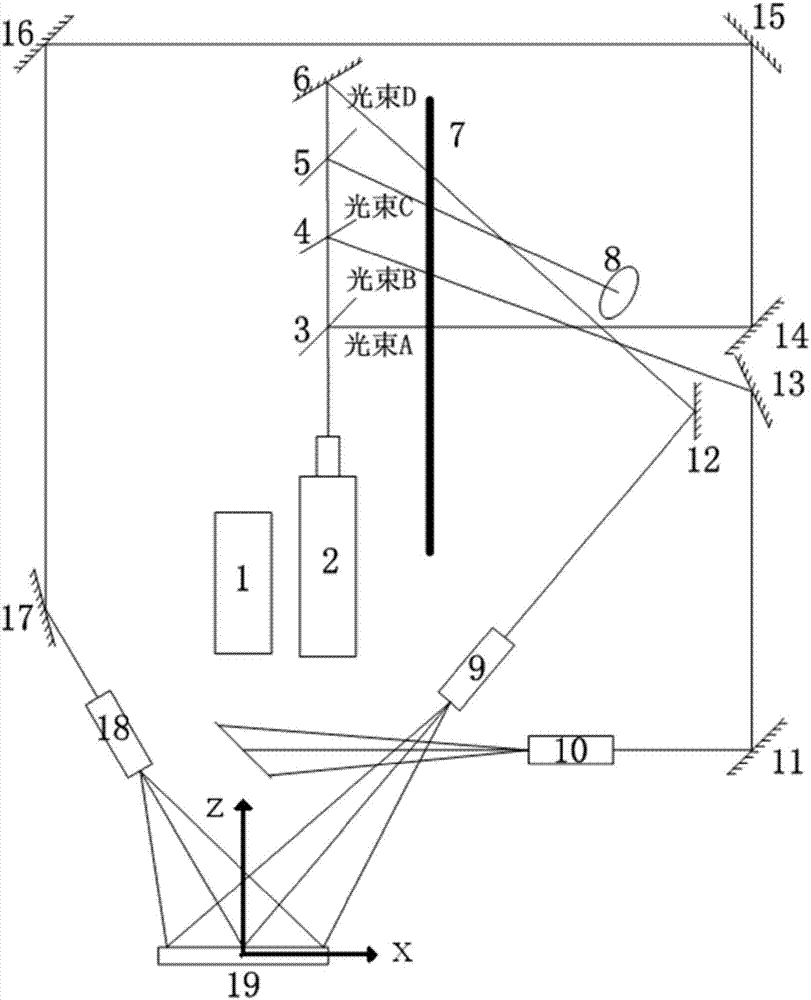

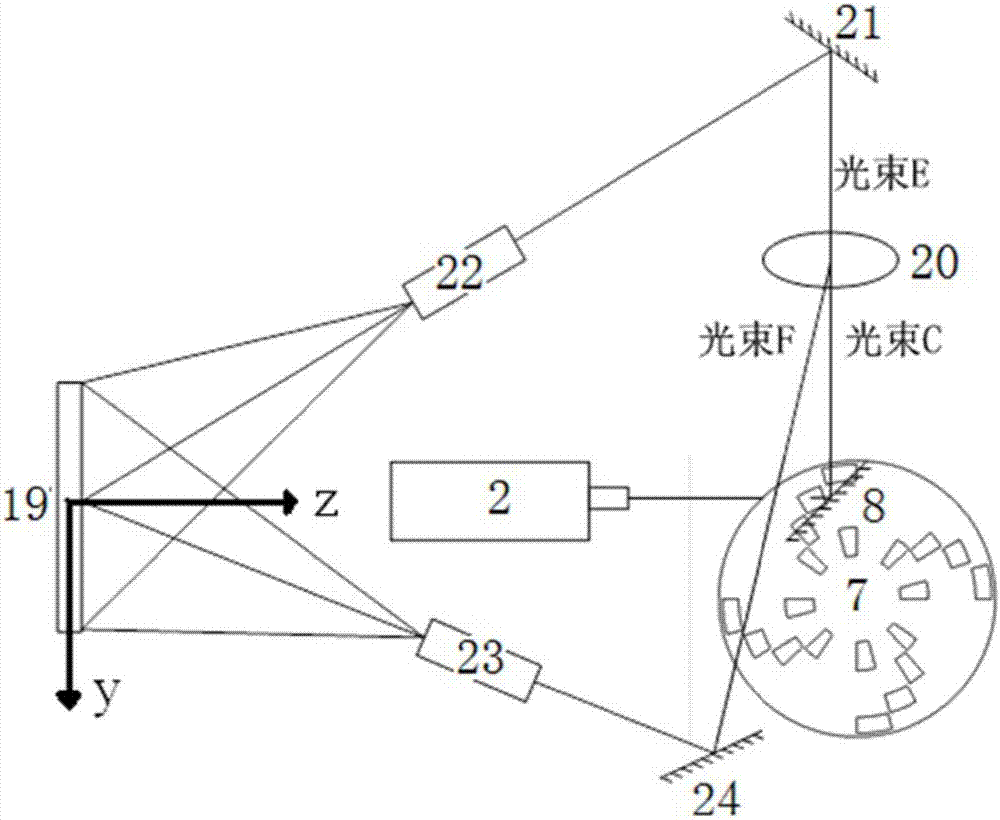

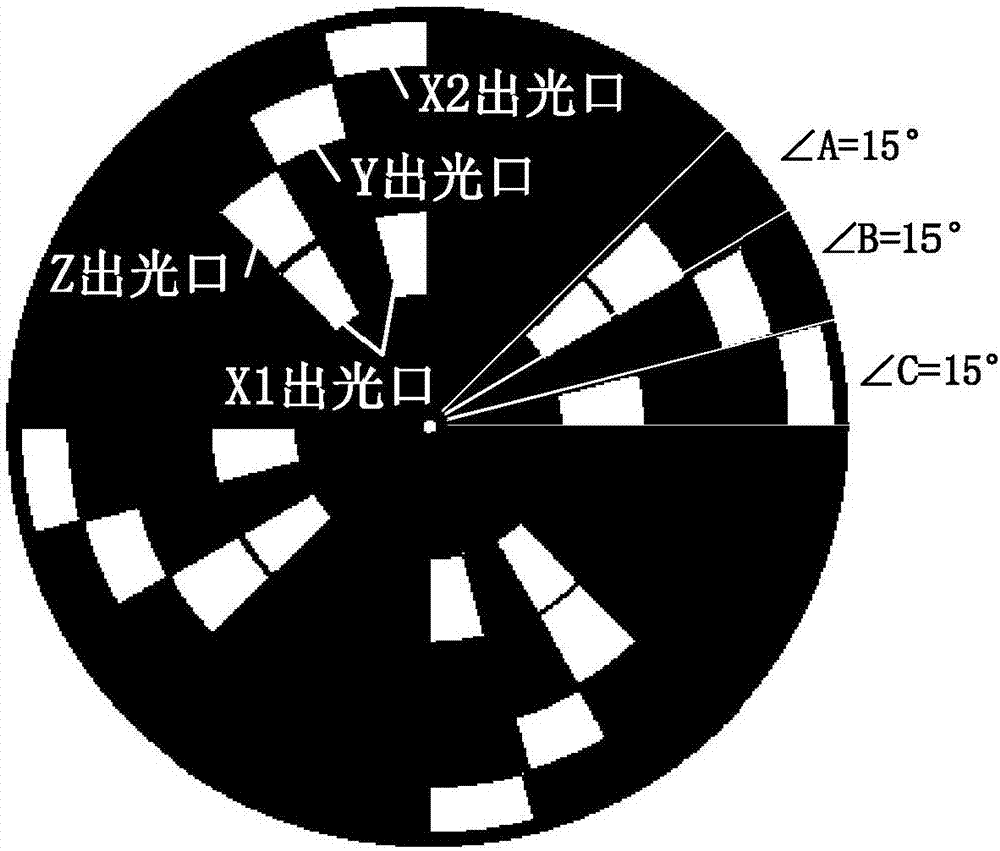

[0033] The measurement device consists of laser 2, high-speed camera 1, optical system, computer and measurement software: laser 2 uses a 532nm single longitudinal film Nd:YAG laser; high-speed camera 1 is used to collect speckle images; computer is used to store speckle images ; The measurement software uses the speckle interference fringe image collected by the high-speed camera to calculate the three-dimensional deformation; the optical system such as figure 1 , 2 As shown, the beam of the laser is divided into five paths by the beam splitter multiple times, and the deformation measurements in the x, y, and z directions are carried out respectively, where the z direction is the direction perpendicular to the high-speed camera 1, and the direction pointing to the high-speed camera 1 is positive; the x direction is the horizontal direction, positive as figure 1 shown; the y direction is determined by the right-hand rule; the origin is the center of the surface of the tested ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com