Tunnel three-dimensional stress field simulator

A simulation device and stress field technology, applied in measurement devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of simulation limitations, distortion of mechanical parameters of model tunnels, inability to simulate the freezing auxiliary method of connecting cross-channels, etc. The effect of reliable data and rich surrounding rock stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

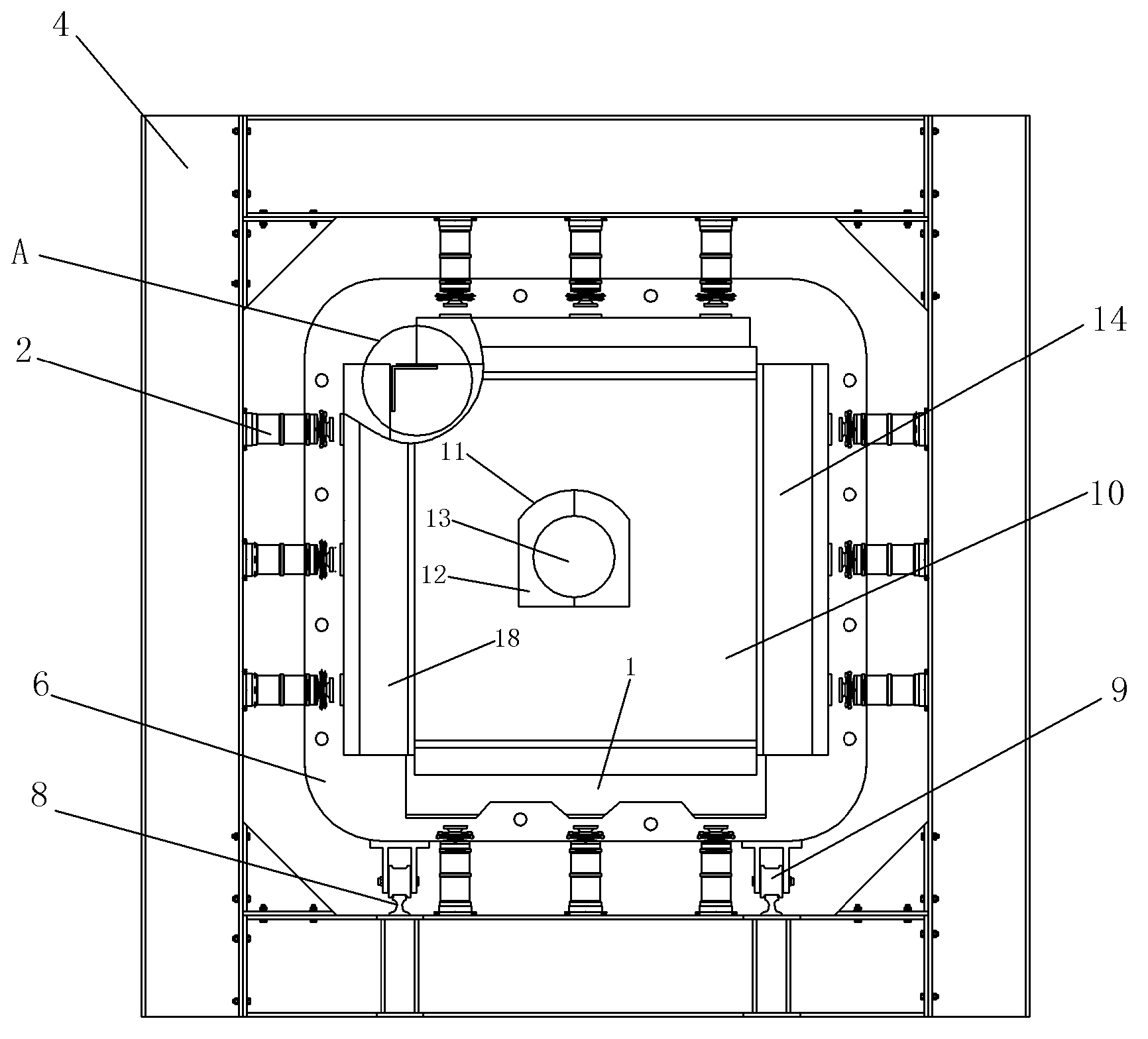

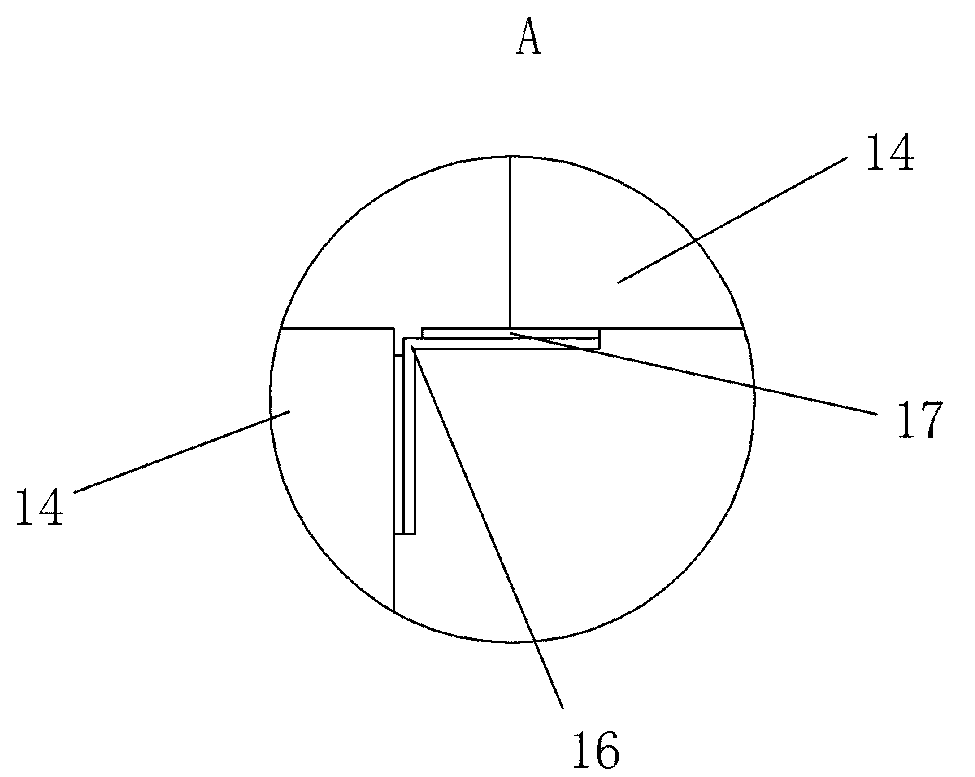

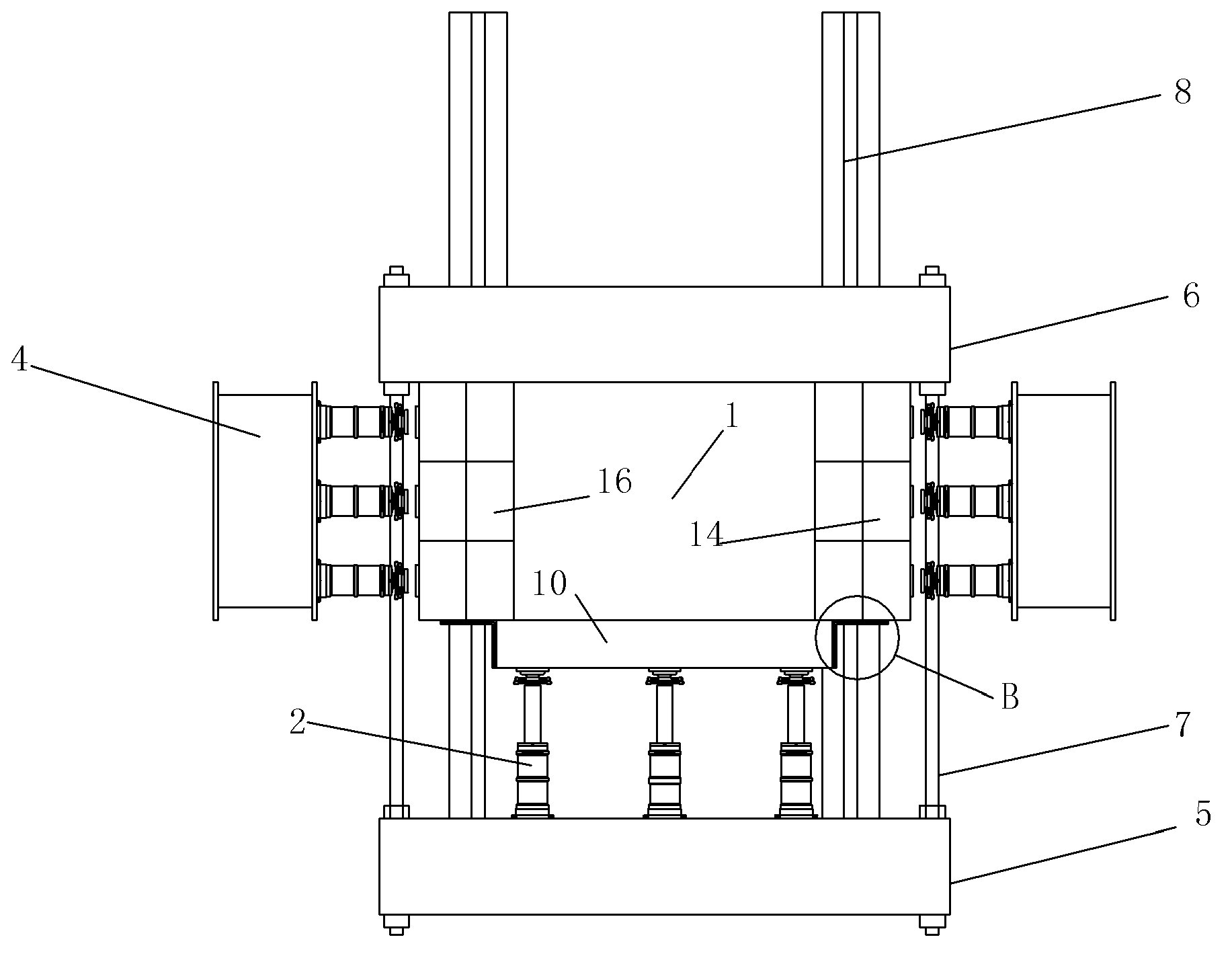

[0028] Figure 1-Figure 4 It is shown that a specific embodiment of the present invention is a tunnel three-dimensional stress field simulation device, including a test box 1, a jack 2, and a hydraulic loading and control device. The test box 1 is placed in a frame-shaped load beam 4, the front of the test box 1 is provided with a front load plate 5, the rear wall of the test box 1 is a rear load plate 6, and the front load plate 5 and the rear load plate 6 are surrounded by pull rods 7 connection, the inner side of the load beam 4 and the inner surface of the front load plate 5 are fixed with a jack 2; the bottom of the load beam 4 is provided with two longitudinal support rails 8, and the pulley 9 at the bottom of the front load plate 5 and the rear load plate 6 Cooperate with support rail 8.

[0029] The specific composition of the test box 1 of this example is: the front wall of the test box 1 is an integral steel plate 10, the middle part of the steel plate 10 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com