Torsional moment and force loading unit for shield excavation simulation

A technology of loading device and shield tunneling, which is applied in the direction of measuring device, machine/structural component testing, instrument, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

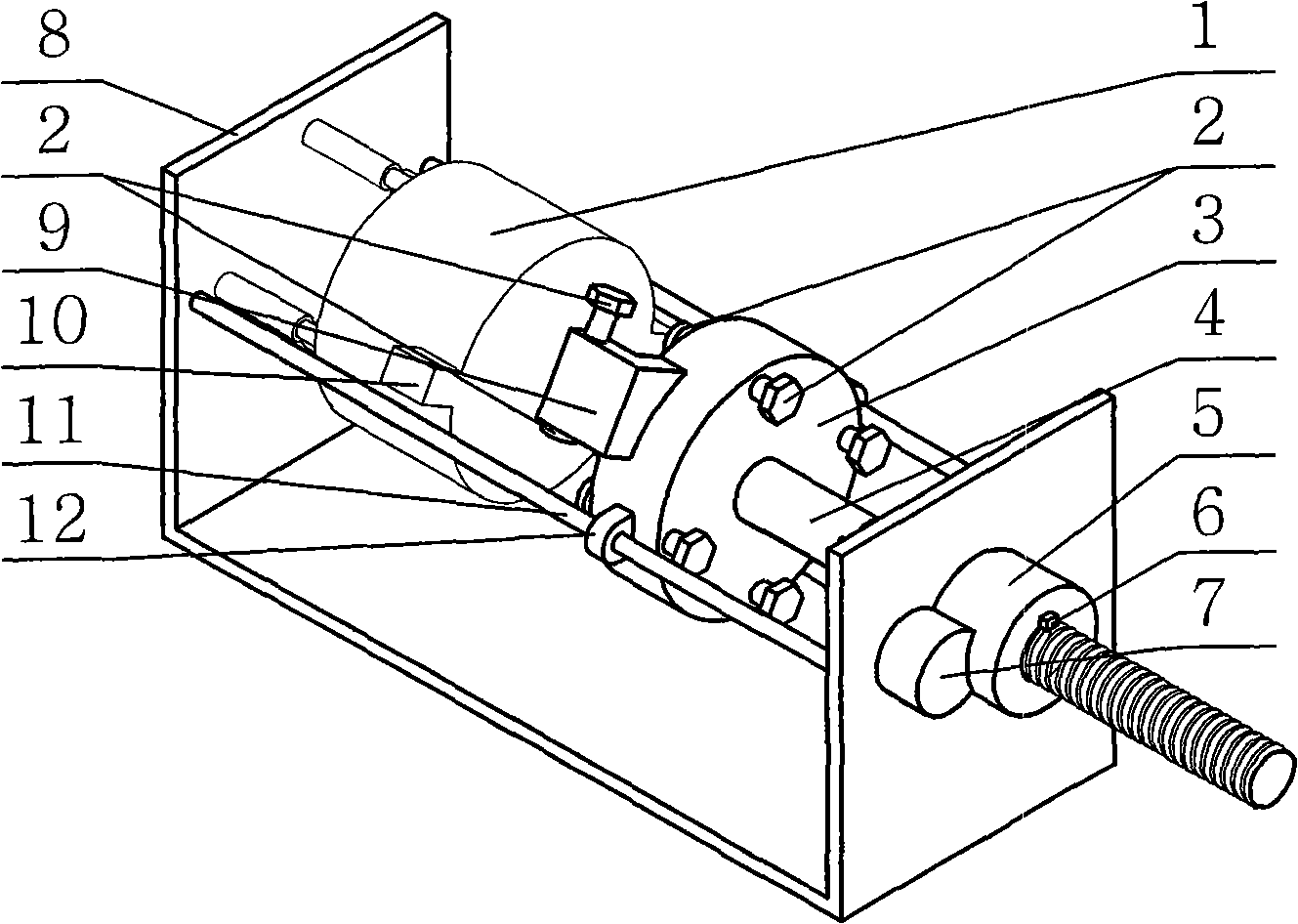

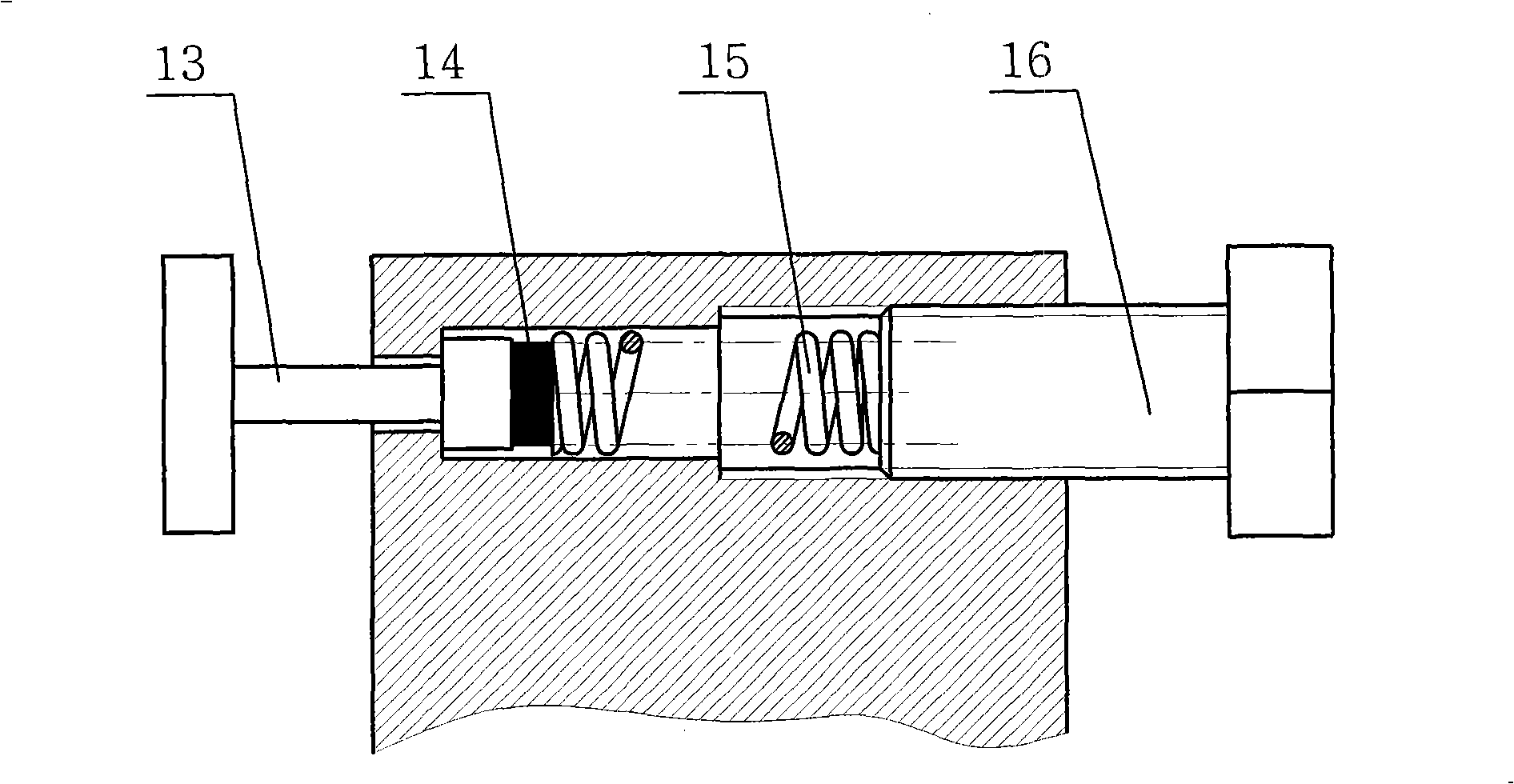

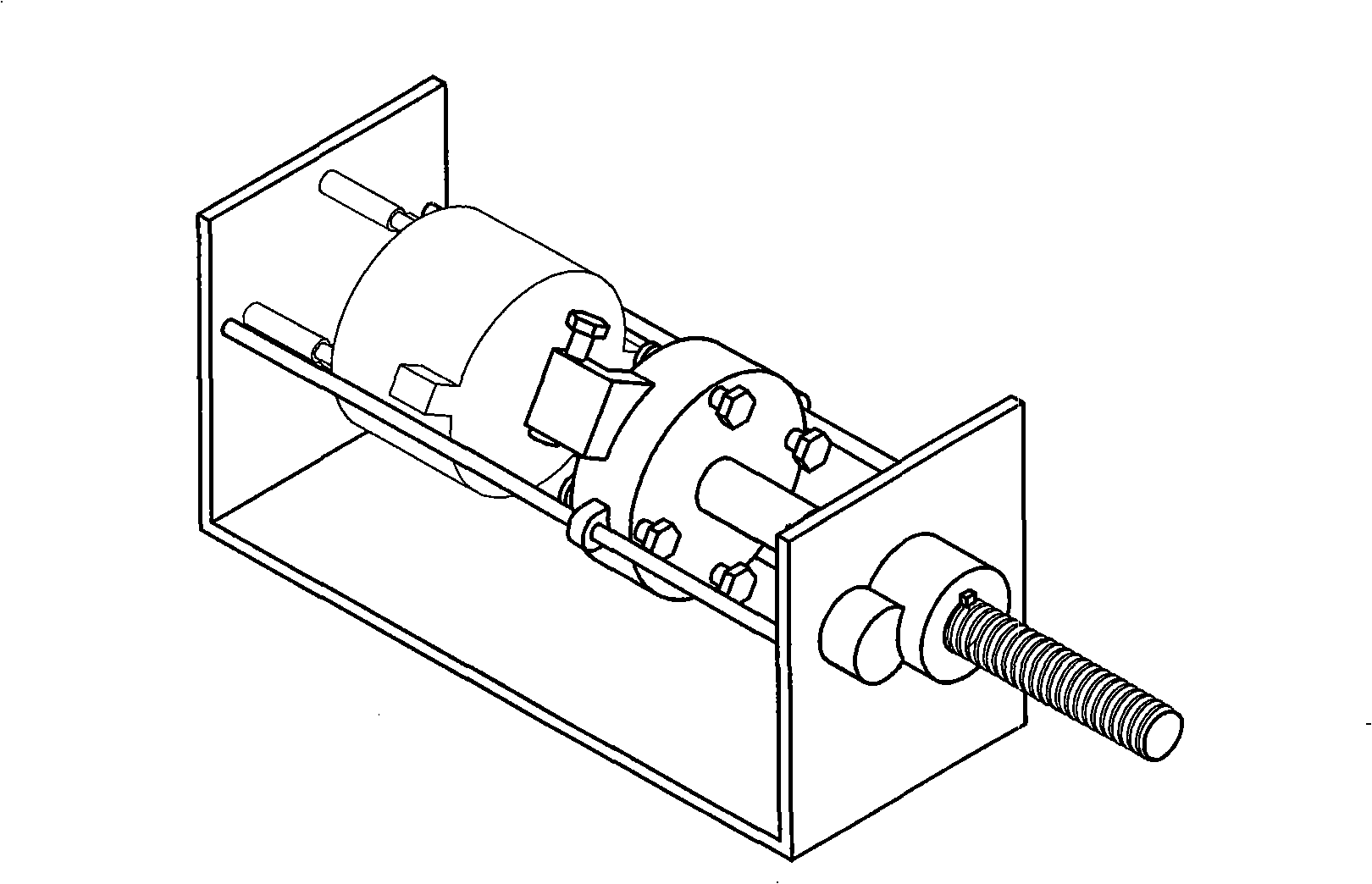

[0021] Such as figure 1 As shown, this embodiment mainly includes a loading disc 3 , a set of force loading unit installed on the loading disc 3 , a set of torque loading unit and a linear motion system. The specific structure is as figure 1 As shown, it includes a frame 8, a loading tray 3, and a simulated shield head 1. The simulated shield head 1 is arranged at the left end of the frame 8 , and the loading disk 3 is arranged at the right end of the frame 8 . A pair of horizontal slide rails 11 are also fixed on the frame 8, and the connectors 12 fixed on both sides of the loading tray are sleeved on the outer surface of the slide rails, so that the loading tray can slide along the slide rails, and the axis of the loading tray 3 is in line with the analog The axis of shield head 1 is on a straight line. A pair of force-bearing protrusions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com