Centralized water discharge apparatus and method for tunnelling

A tunnel engineering and tunnel technology, which is applied in safety devices, drainage, earthwork drilling and mining, etc., can solve the problems of deteriorating construction operation environment, water seepage, water leakage, etc., and achieve the effect of simple construction, high efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

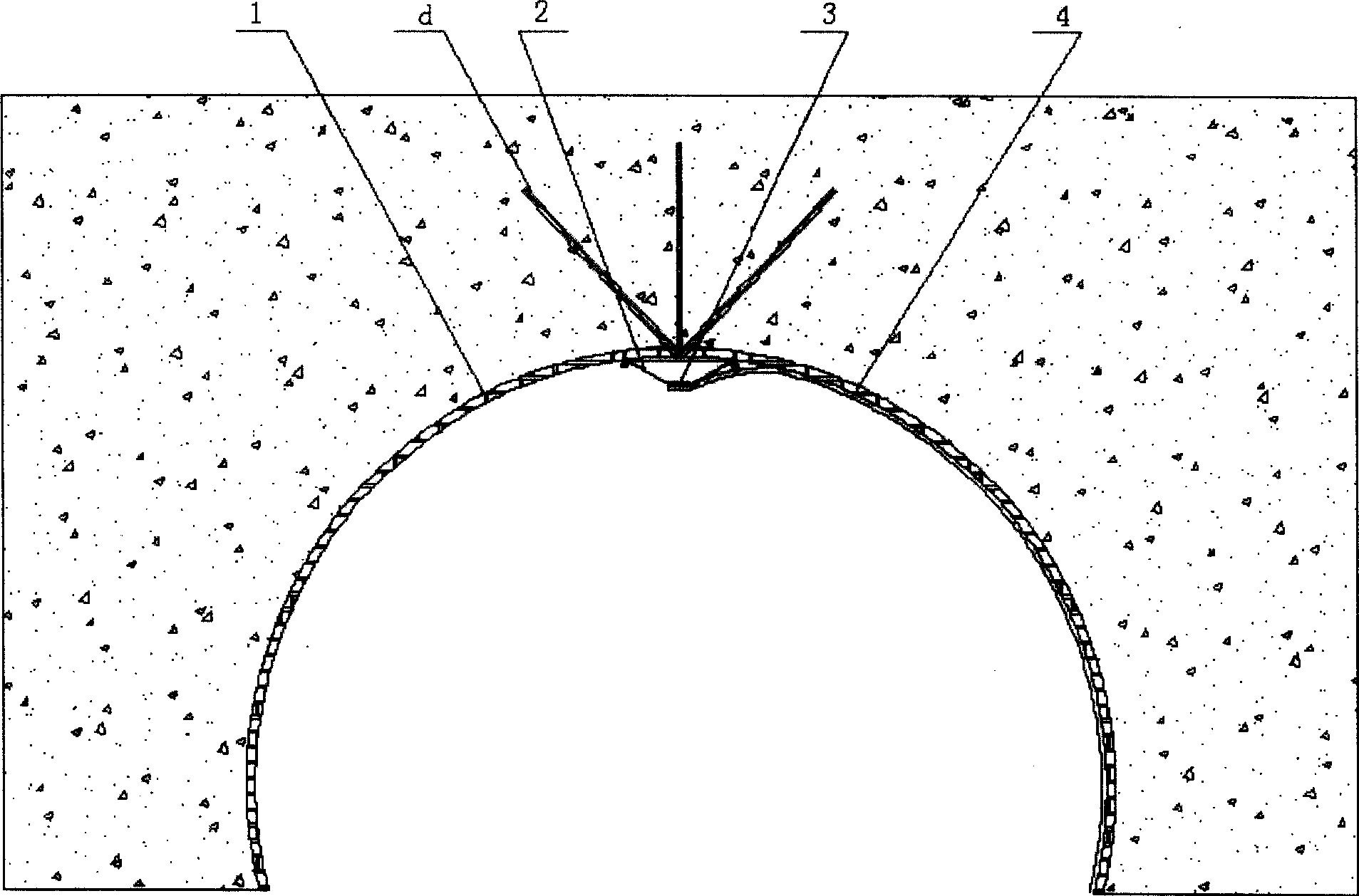

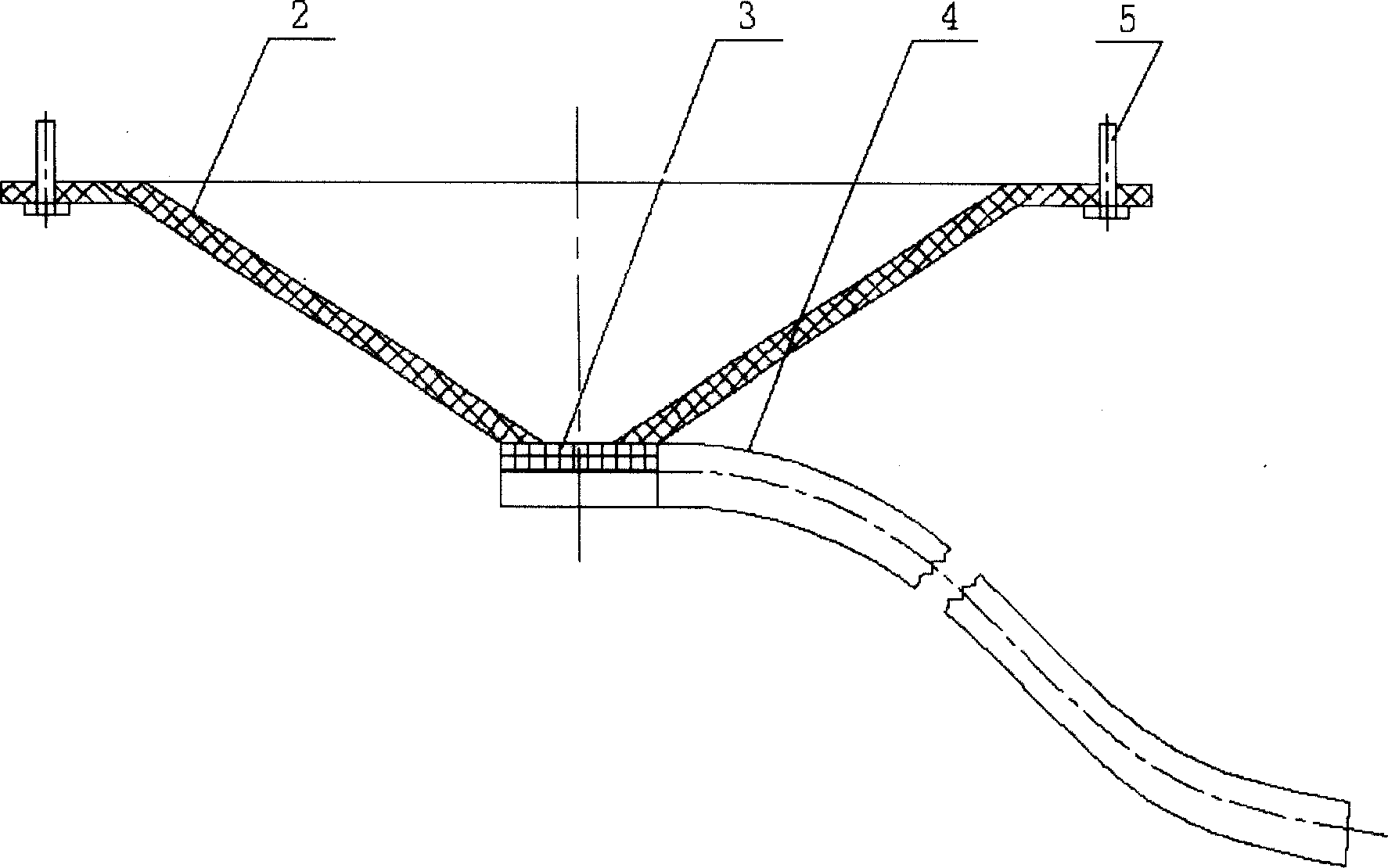

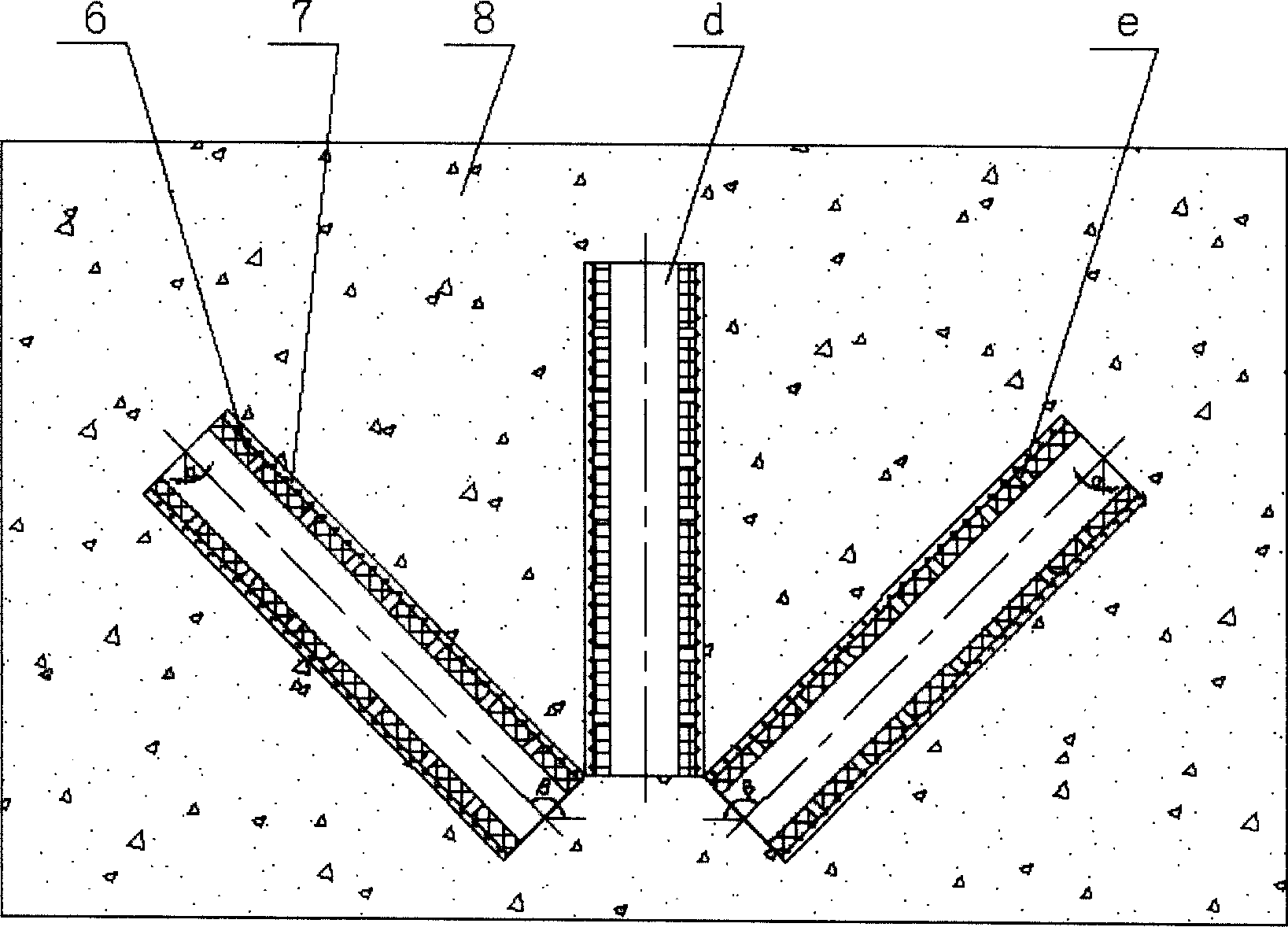

[0027] exist figure 1 , 2 , 3, the centralized drainage device of the tunnel engineering of the present embodiment is made of funnel 2, filter screen 3, drainpipe 4, expansion bolt 5, diversion pipe 6, filter cloth 7. In the initial support 1 in the tunnel and in the water diversion hole d of the water seepage concentrated part of the tunnel surrounding rock 8, the water diversion pipe 6 is installed. The water diversion pipe 6 of the present embodiment is a polyvinyl chloride pipe, a nylon pipe, or a stainless steel pipe can also be used. The radial processing of the water diversion pipe 6 has a water seepage hole e, and the water leaked from the surrounding rock of the tunnel 8 can enter the water diversion pipe 6 from the water seepage hole e, and wrap the non-woven fabric outside the water diversion pipe 6, and the non-woven fabric is the filter cloth 7 An embodiment, also available nylon or plastics gauze, filter cloth 7 is used for preventing silt from clogging the seep...

Embodiment 2

[0036] In this embodiment, the shape of the funnel 2 is a quadrangular prism whose upper base is larger than the lower base. The shape of the funnel 2 can also be a triangular prism with the upper bottom larger than the lower bottom, or a hexagonal prism with the upper bottom larger than the lower bottom, or a pentagonal truss or other prisms with the upper bottom larger than the lower bottom. . Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0038] In this embodiment, three water diversion holes d in different orientations and different directions converging at one point are drilled in the primary support 1 and the tunnel surrounding rock 8 where seepage is concentrated. The angle α is 30°, the angle β between the centerline of the water diversion hole and the horizontal plane is 135°, and the three water diversion holes d are evenly arranged on the same cone surface. The depth of the water diversion hole d is 2m, and the diameter of the water diversion hole d is 10cm. The centralized drainage device of the tunnel engineering used is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com