Single-track railway tunnel lining trolley

A technology for lining trolleys and single-track railways, applied in tunnel lining, tunnel, shaft lining, etc., can solve the problems of long load time, high labor intensity, and high construction cost, and achieve improved production efficiency, reduced labor intensity, and reduced construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

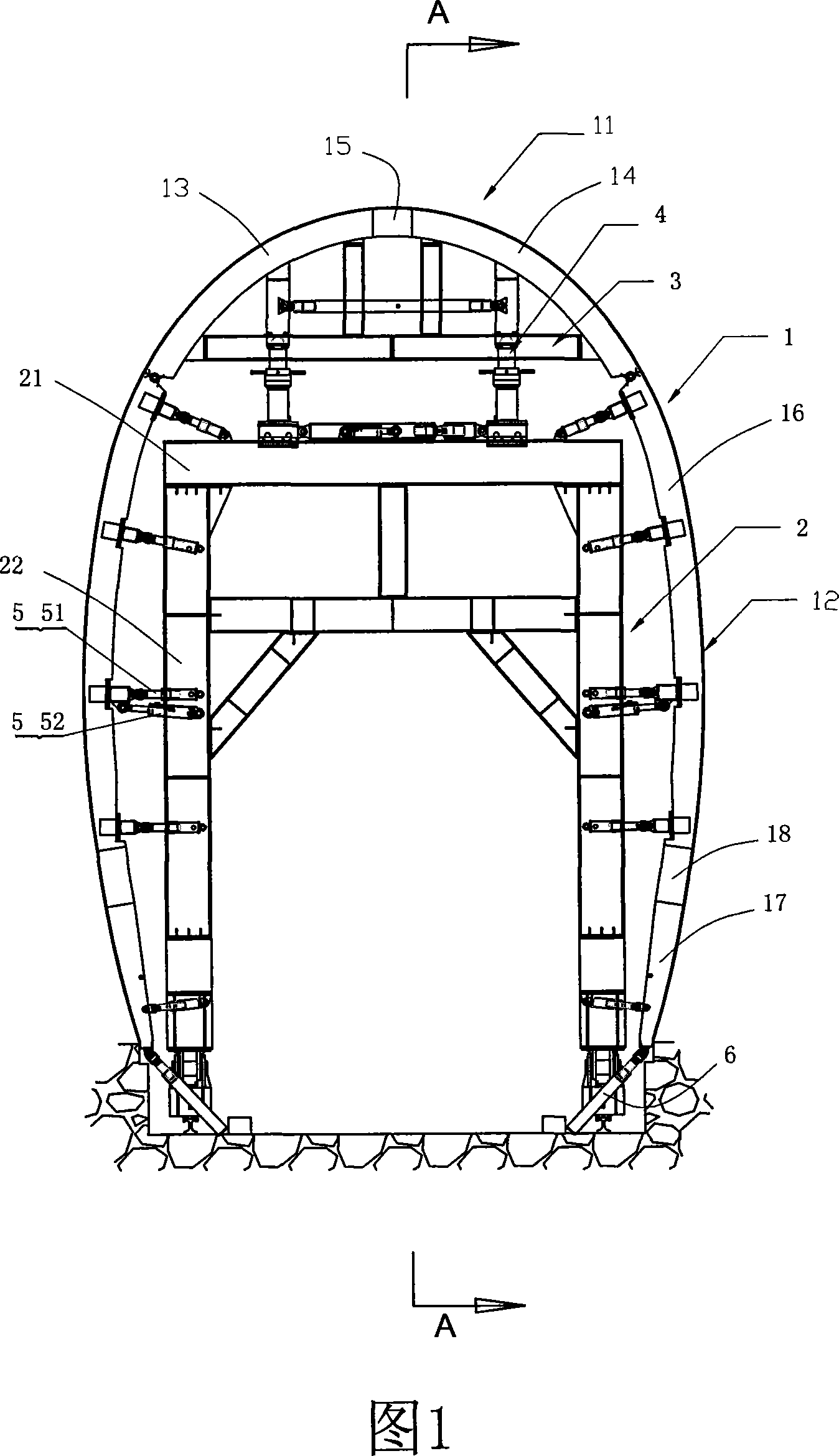

[0012] Embodiment 1: See Figure 1

[0013] It can be seen from Figure 1 that the present invention still includes the arched mold 1, the mast 2, the bracket 3, the jacking cylinder 4. The arched mold still includes the top template 11 and the two side templates 12, the top template 11 and the two sides The templates 12 are hinged, but the top template of the present invention is composed of a left top template 13, a right top template 14 and a top adjustment template 15. The left top template 13 and the right top template 14 are symmetrically located on the left and right sides of the top adjustment template 15. And connected by bolts, the top adjustment template 15 can be adaptively selected according to the width of the tunnel, either wide or narrow. Both sides of the template 12 are divided into an upper template 16 and a lower template 17, and a side adjustment template 18 can be added between the upper and lower templates, between the upper template 16 and the lower template ...

Embodiment approach 2

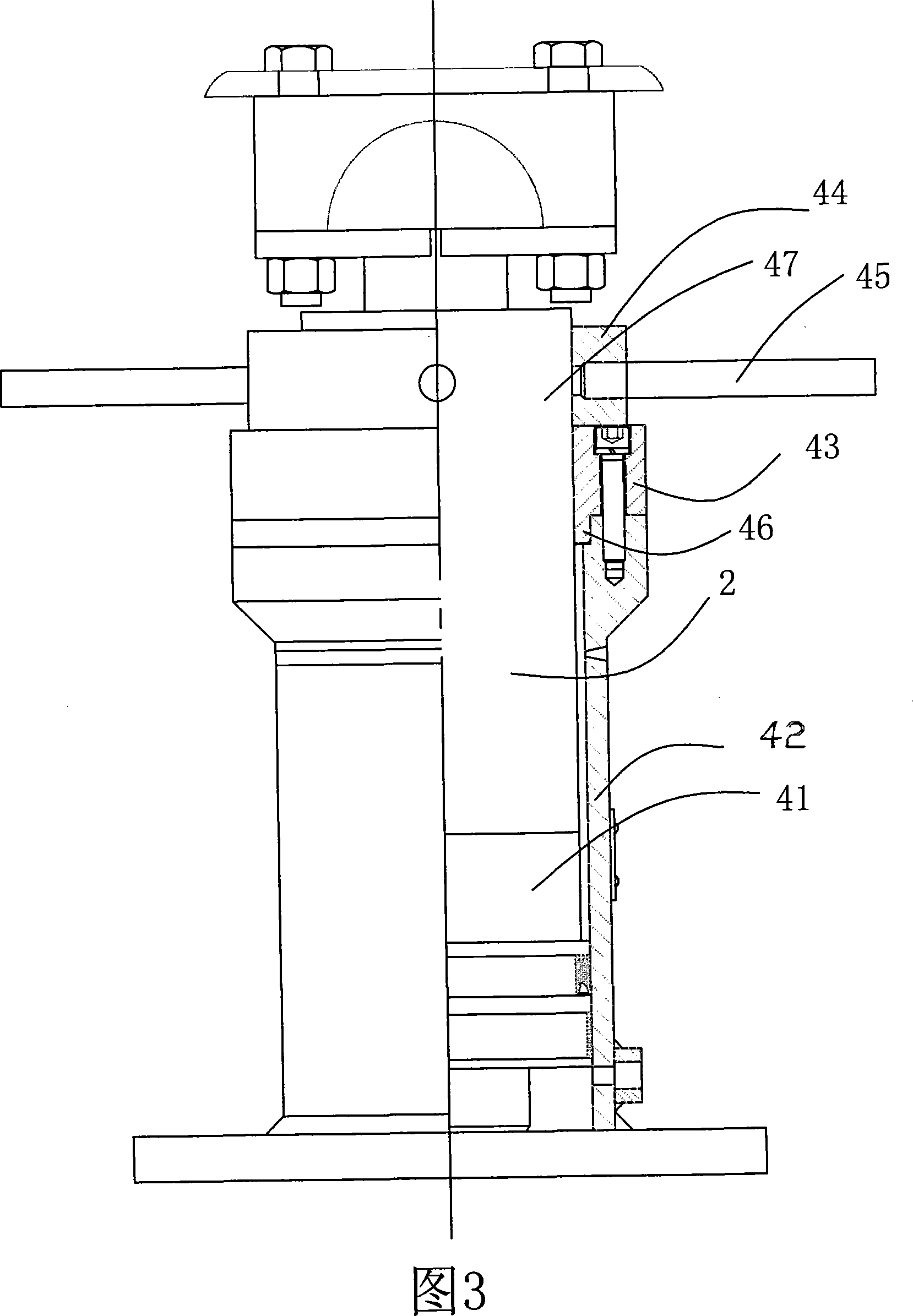

[0014] Embodiment 2: See Figure 3

[0015] This is an improved example of the jacking cylinder 4 based on the first embodiment.

[0016] In this embodiment, the jacking cylinder 4 still has a piston rod 41, a cylinder tube 42, and a guide sleeve 43, as well as a lock nut 44 and a handle 45. The guide sleeve 43 is provided with a step 46, and the guide sleeve 43 is mounted on the cylinder 42 One end, and its step 44 extends into the cylinder tube 42, the piston rod 41 extends from the guide sleeve 43, the extension section 47 of the piston rod 41 is provided with an external thread, the lock nut 44 and the outer thread on the piston rod 41 Threaded fit, the handle 45 is mounted on the lock nut 44. In this way, when the piston rod is subjected to a lateral force, it is ensured that the guide sleeve can reliably decompose the lateral force generated by the piston rod to the cylinder barrel, so as to ensure that the cylinder 42 and the guide sleeve 43 are only under pressure and not s...

Embodiment approach 3

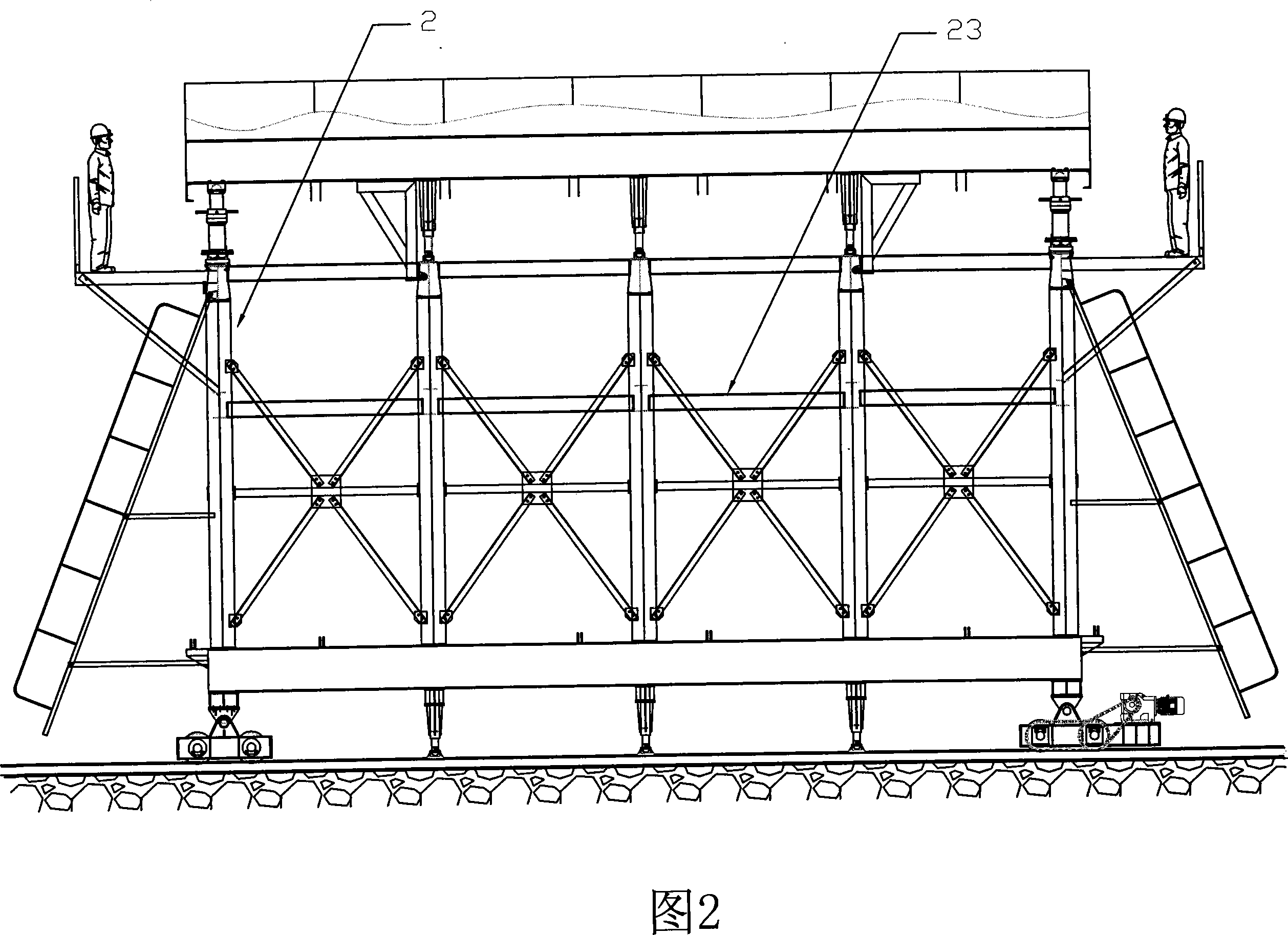

[0017] Embodiment 3: See Figure 1-Figure 2.

[0018] This embodiment is a single-track railway tunnel lining trolley very suitable for railway tunnels.

[0019] In this embodiment, the door frame 2 is rectangular, and is composed of an upper cross beam 21 and two upright columns 22. The two upright columns 22 are respectively located at the two ends of the cross beam 21 and are vertically and fixedly connected to the cross beam. At least three door frames 2 are used. In this embodiment, five door frames are used. These door frames are equidistantly arranged in the arch mold 1 and the door frames are connected by a truss 23. The supporting member 5 supporting the templates 12 on both sides adopts a number of jacks 51 and lateral cylinders 52. These jacks and lateral cylinders are evenly distributed at each mast 2 and installed symmetrically. One end is connected to the mast 2 and the other end is connected to the side. On the template, one of the lateral cylinders can be installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com