Plasma drilling bit

A drilling bit and plasma technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc., can solve technical problems that cannot be solved, and achieve the effect of increasing mechanical penetration rate, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

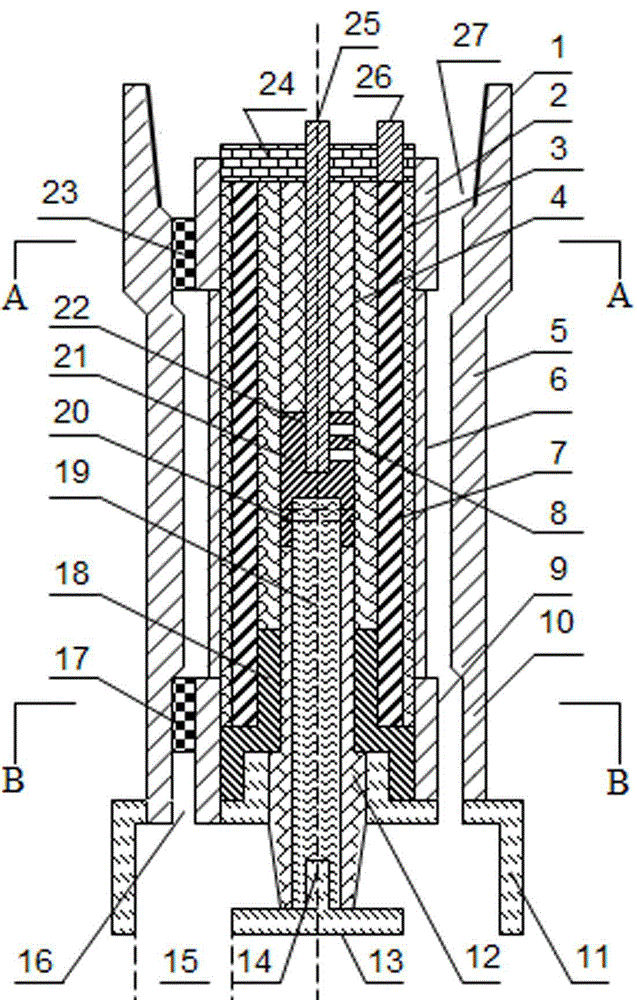

[0029] A plasma drilling bit, in which an axially penetrating fluid channel and an electrode through hole are preset in the drill body, a high-voltage positive electrode and an insulator are fixed in the electrode through hole, a cup-shaped ground electrode is fixed in the bottom of the drill body, and the bottom of the high-voltage positive electrode is For the high-voltage disk electrode, an annular inter-electrode gap is reserved between the high-voltage disk electrode and the cup-shaped ground electrode.

[0030] This embodiment gives the basic technical route. After satisfying the basic conditions such as having a fluid channel, a high-voltage positive electrode and a cup-shaped ground electrode, the plasma drilling work can be completed by cooperating with ground equipment.

Embodiment 2

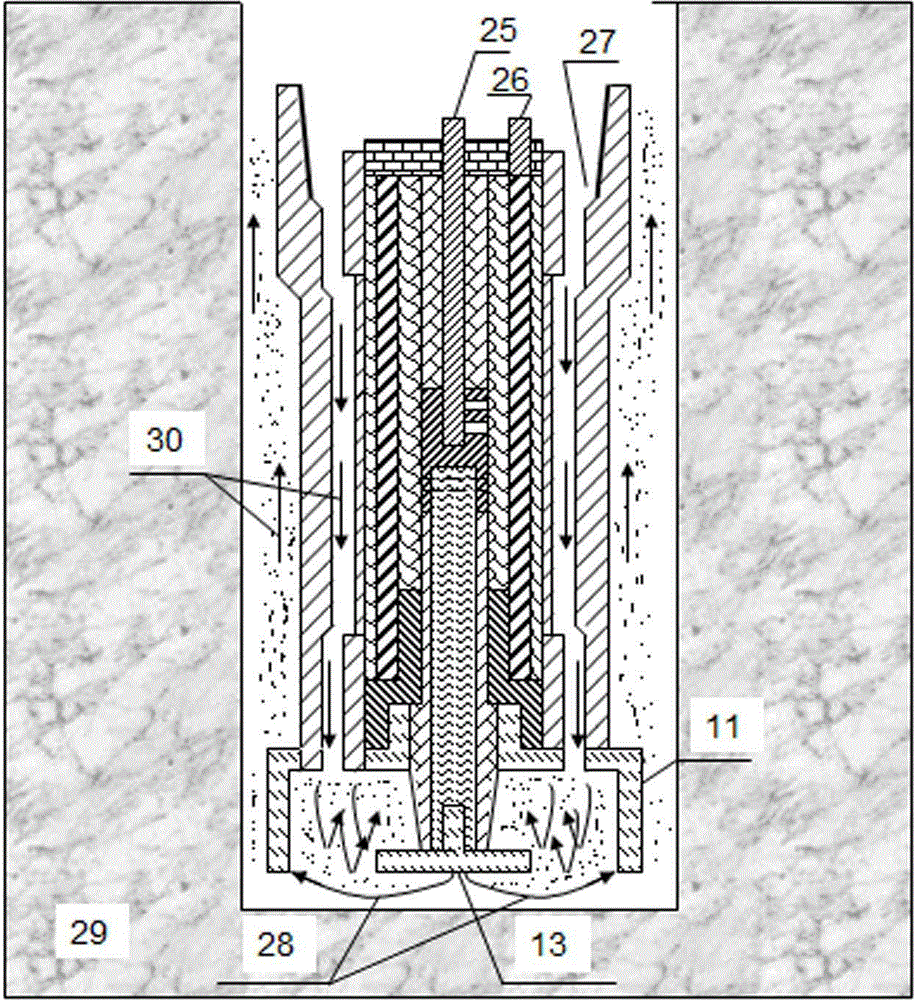

[0032] Refer to the attached figure 1 , figure 2 with image 3 , a plasma drilling drill bit, comprising an outer pipe upper joint 1, an outer pipe body 5, an outer pipe lower joint 10, an inner pipe upper joint 2, an inner pipe body 6, an inner pipe lower joint 9, an upper righting block 23, and a lower righting block 17. High-voltage plate-mounted electrode 13, cup-shaped ground electrode 11, high-voltage handle 19, conductive sleeve 18, connector 21, metal tube 7, pressure cap 24, cable core 25, 26, insulator 3, 4, 12.

[0033]The upper joint 1 of the outer pipe, the body 5 of the outer pipe and the lower joint 10 of the outer pipe are sequentially friction-butt welded to form the outer pipe; The outside of the upper pipe joint 2 and the lower joint 9 are arranged with 3 centralizing blocks 23, 17 along the circumference at intervals of 120°; The outer side of the lower joint 9 of the inner pipe and the lower centralizing block 17 are all provided with threaded steps an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com