Improved structure of clamping jaw for printed circuit board drill bit ring assembling machine

A technology of printed circuit board and improved structure, which is applied in chucks, manipulators, metal processing, etc., and can solve the problems of chuck wear, short distance, and drop of jaws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] combine Figure 1 to Figure 3 The present invention is described in further detail.

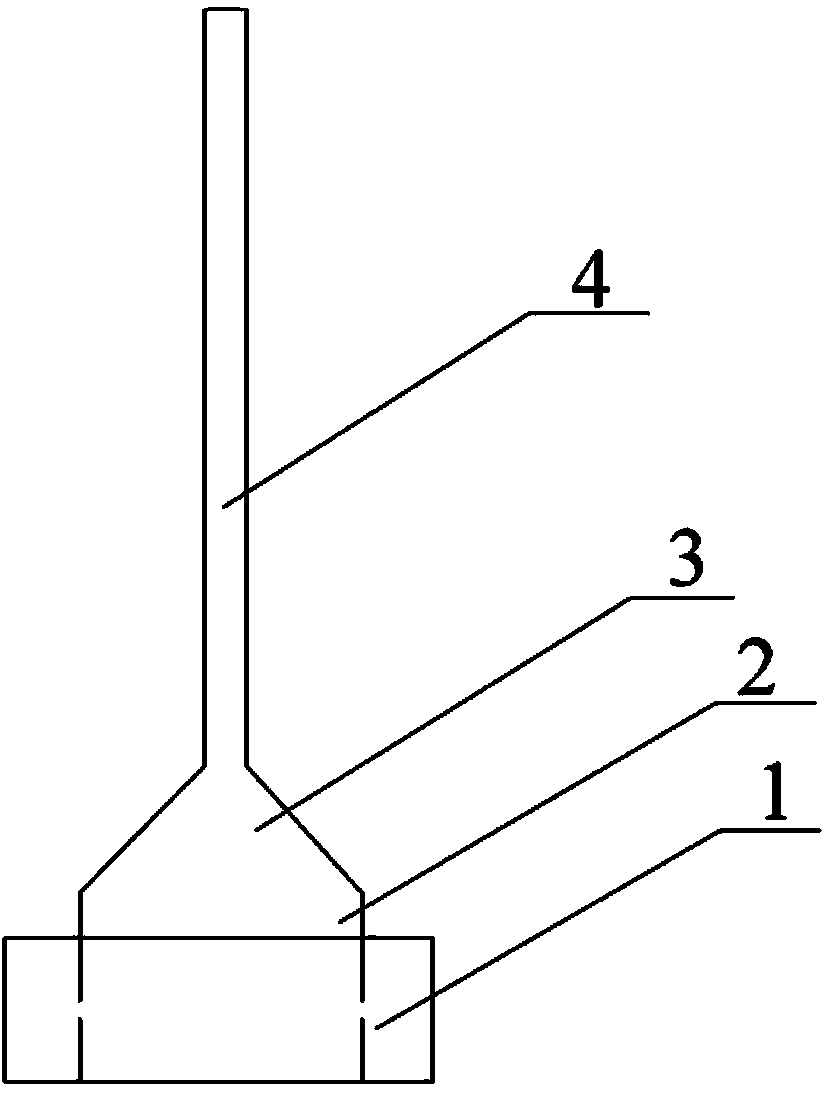

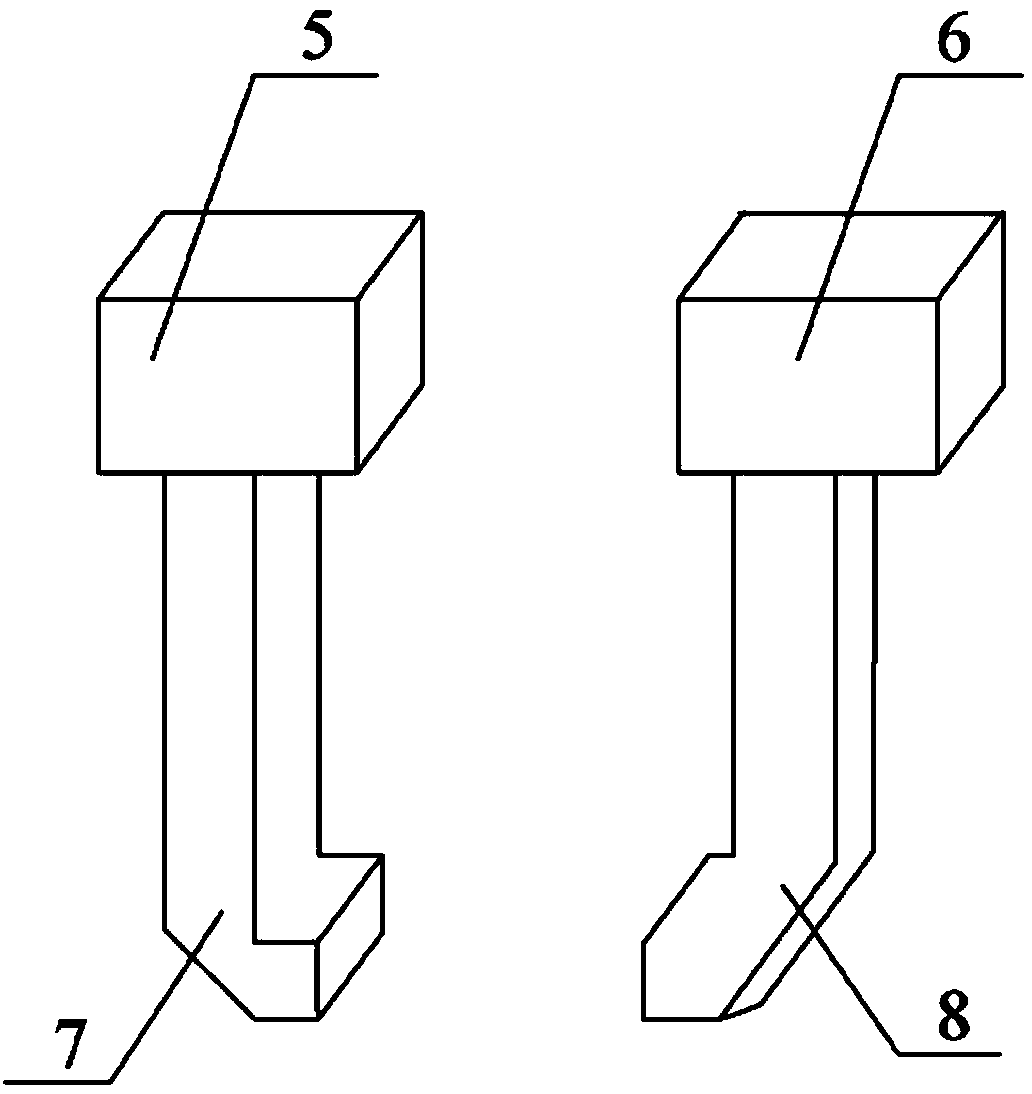

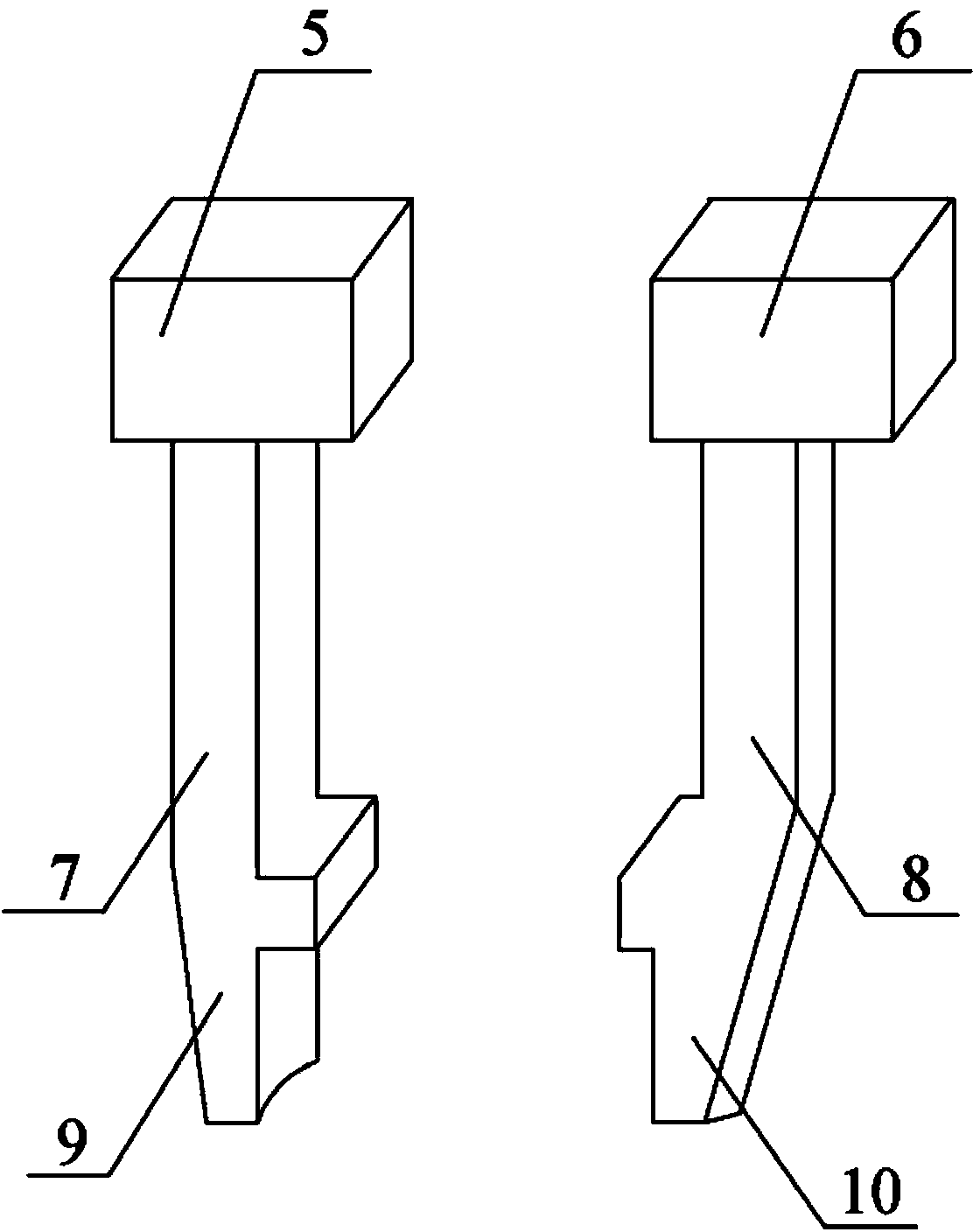

[0024] An improved structure of the clamping jaws for the upper ring machine of printed circuit board drills, including a first clamping jaw 5 and a second clamping jaw 6 capable of relative clamping, and a first clamping head 7 is provided at the end of the first clamping jaw , the end of the second jaw is provided with a second chuck 8, the first and second chucks are opposing clamping blocks, and the end of the first chuck 7 extends downward to form a first clamping end 9 , the end of the second chuck 8 extends downwards to form a second clamping end 10 , and the opposite surfaces of the first and second clamping ends are shaped to match the outer peripheral surface of the collar 1 . Wherein the first clamping head 7 is a clamping block with an "L"-shaped structure, and the second clamping head 8 is a clamping block that is mirror image symmetrical to the first clamping head. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com