Anti-adhesion device for tobacco packaging box before printing

A packaging box and anti-adhesion technology, applied in the direction of transportation and packaging, object separation, pile separation, etc., can solve problems such as paper jams in printing machines, affect the quality of packaging boxes, and uneven shaking of packaging boxes, and achieve the effect of preventing confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

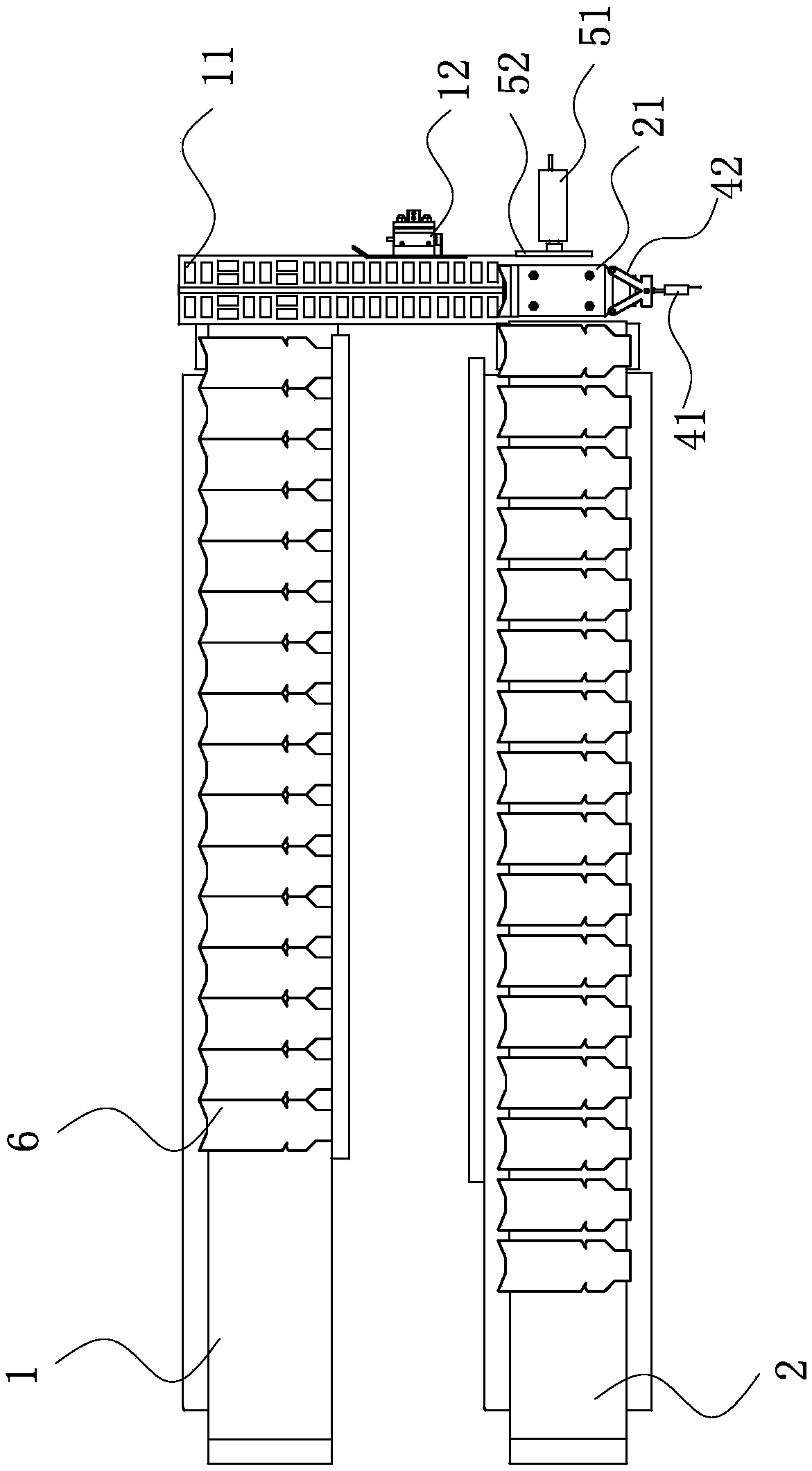

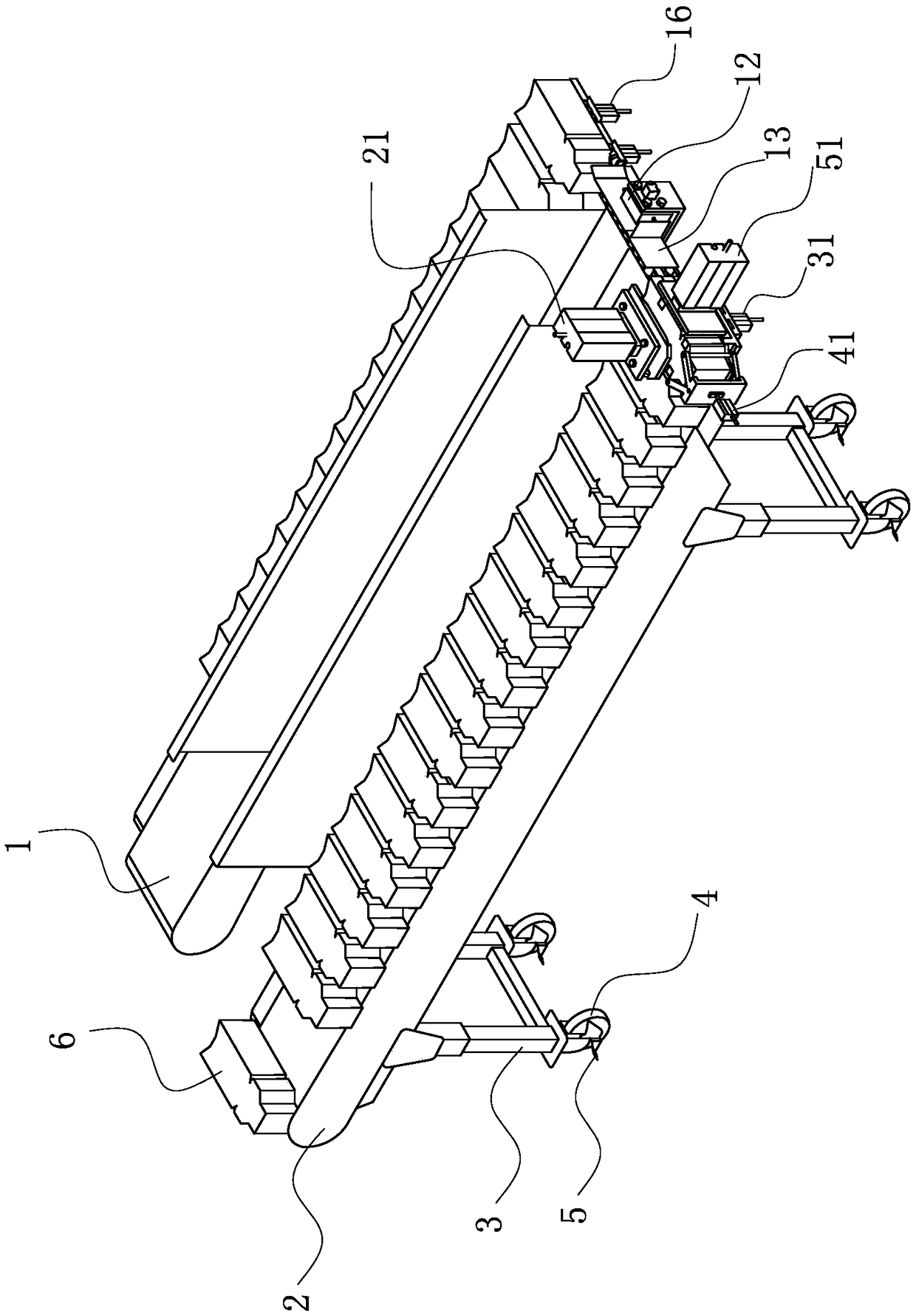

[0029] like figure 1 and figure 2 As shown together, a pre-printing anti-adhesion device for tobacco packaging boxes in this embodiment includes a feed conveyor belt 1, a discharge conveyor belt 2, a support, a push mechanism, a paper pressing mechanism and an alignment mechanism, and the two ends of the push mechanism are connected to the feed conveyor belt respectively. The conveyor belt 1 and the discharge conveyor belt 2 are connected to form a 匚-shaped structure. Of course, the two ends of the push mechanism are respectively connected with the feeding conveyor belt and the discharge conveyor belt to form a line, but it will take up a long space, and the 匚-shaped structure is preferred.

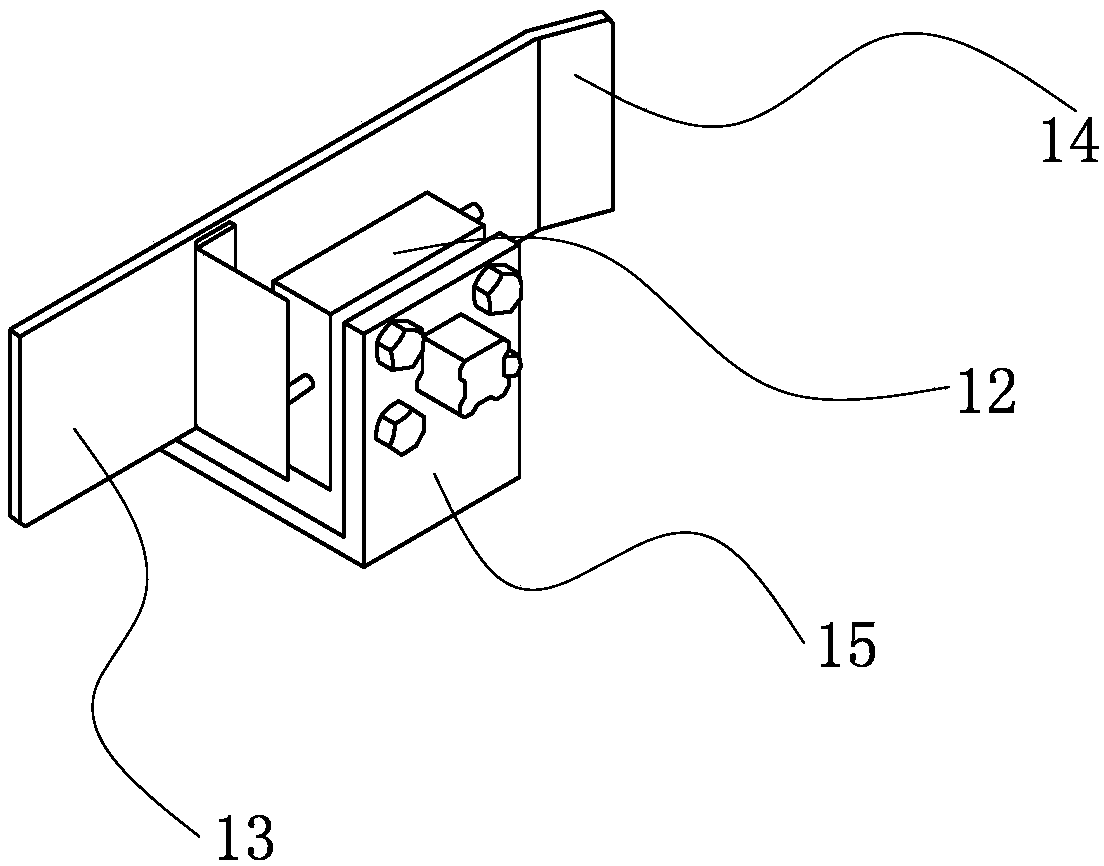

[0030] like figure 1 and figure 2 Commonly shown, the end of the push mechanism close to the feeding conveyor belt 1 is alternately provided with rollers 11 that roll alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com