Di-kalium ion-polymer drilling fluid with strong rejection capability

A technology of potassium ion and strong suppression, applied in the field of drilling fluid, can solve the problems of high solid phase content, drill tool drop, low ROP, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

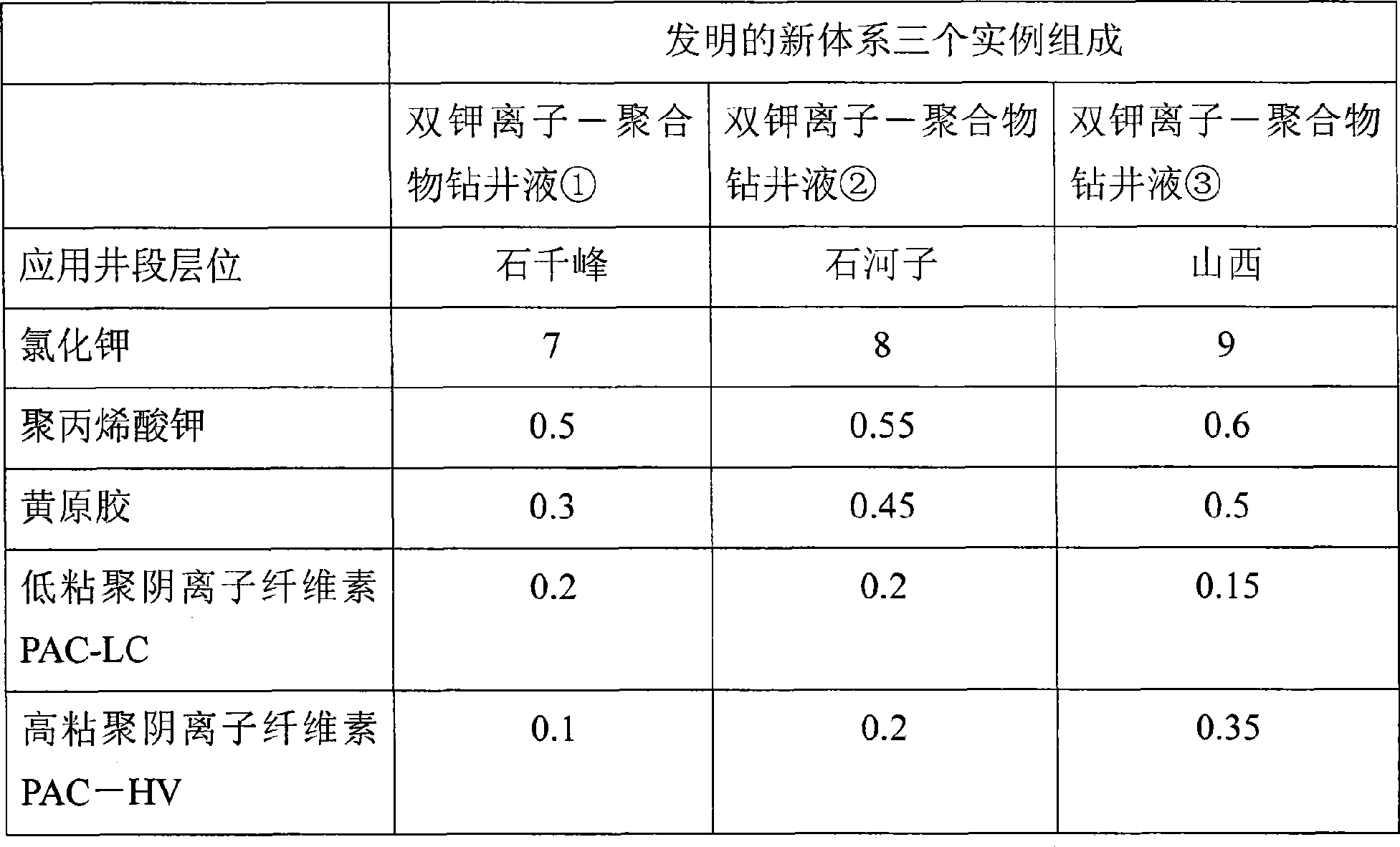

[0073] Example 1 is composed of the above-mentioned invented strong inhibitory dipotassium ion-polymer drilling fluid new system, and its formula composition is shown in Table 6. The formula composition described in ② is prepared on site according to the above-mentioned preparation procedure. Field tests were carried out in 7 wells, among which the results obtained in well CB4-1 are as follows:

[0074] 1. Improve drilling fluid inhibition and stabilize wellbore effect

[0075] ①. Since KPAM and KCL are added to the mud at the ratio of laboratory research, the inhibition and anti-slump of the drilling fluid are greatly increased and the quality of the mud cake is improved. At the same time, the water loss of the drilling fluid is reduced to about 5ml. After 3000 meters, The water loss was further reduced to 3ml. In the whole process of drilling the 121 / 4″ large-scale long open hole section of Well CB4-1, the cumulative reaming of tripping and tripping only took 30 hours, while...

example 2

[0089] Example 2 consists of the above-mentioned invented strong inhibitory dipotassium ion-polymer drilling fluid new system. Its formula composition is shown in Table 6. The formula composition described in ① is prepared on site according to the above-mentioned preparation procedure. The field test of 2 wells has been carried out, and the application in Jingping 16-14 has the following effects:

[0090] ①.Performance of drilling fluid in use:

[0091] Table 7: Example 2 drilling fluid performance table

[0092]

[0093] ②. Shale recovery test

[0094] Samples of dipotassium ion polymer drilling fluids from different formations were taken from the site where they were used, and the shale recovery rate test was carried out to observe its inhibitory effect on shale. It can be seen from the data in the table below that the on-site dipotassium ion polymer drilling fluid system shows very strong shale inhibition in field use, and the average primary recovery rate exceeds 90%....

example 3

[0111] Example 3 consists of the above-mentioned invented strong inhibitory dipotassium ion-polymer drilling fluid new system, and its formula composition is shown in Table 6. The formula composition described in 3. is prepared on site according to the above-mentioned preparation procedure. The field test of 2 wells was carried out, and the application in Shuangping 18-3 also achieved good results, as shown in Table 7.

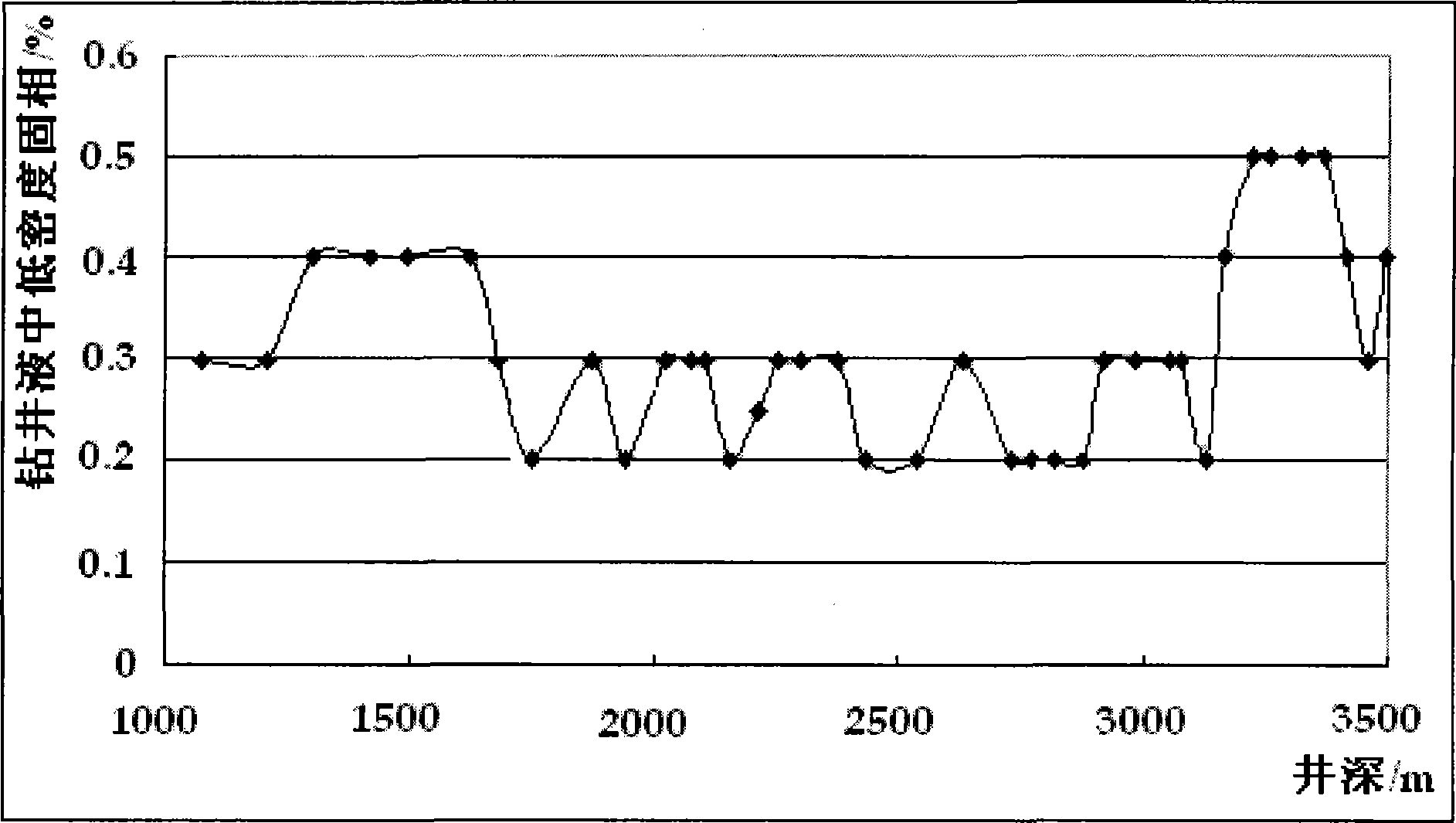

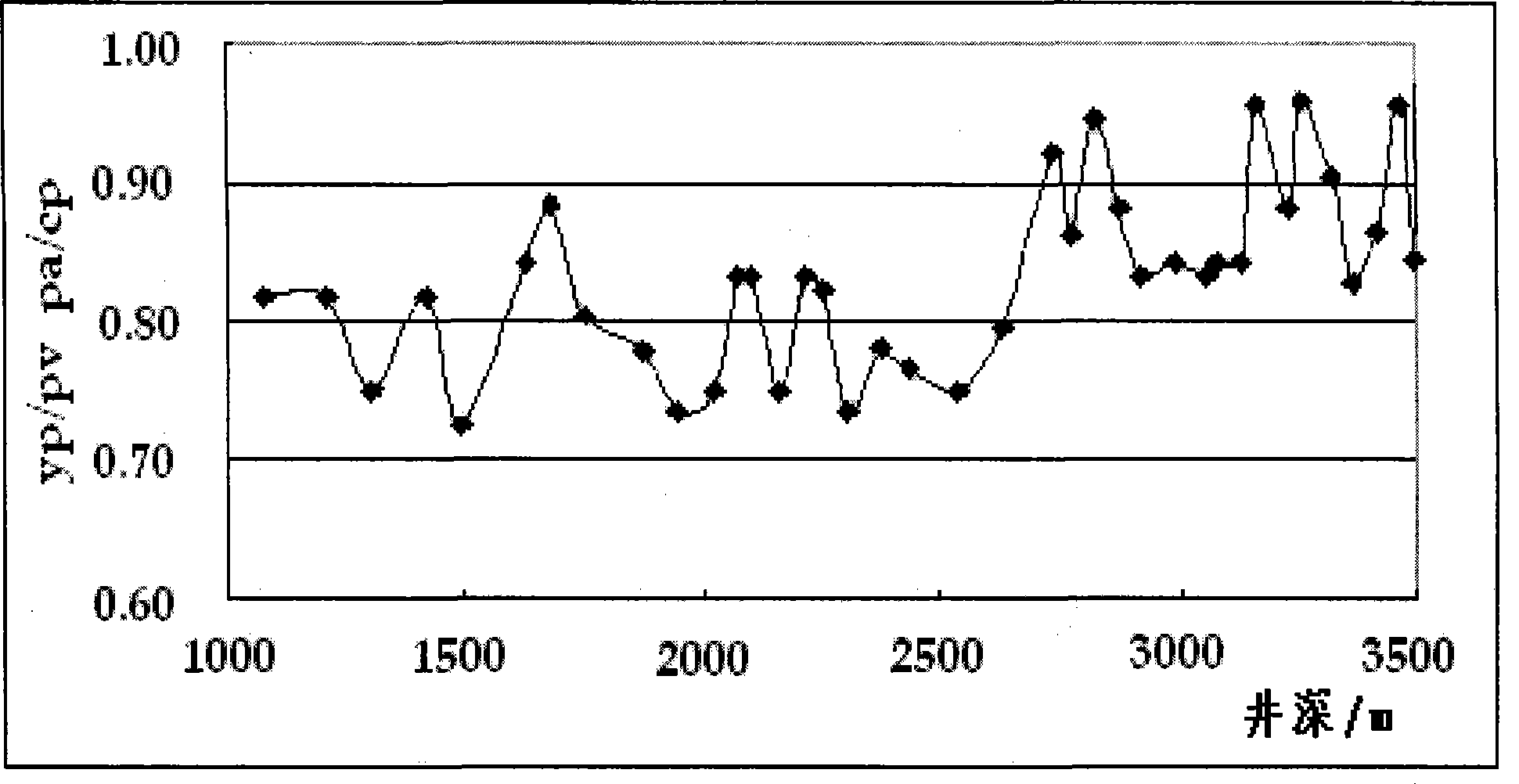

[0112] In the application of the three examples, the system also exhibits good anti-slump inhibition, lubrication, low solid phase, high penetration rate, and the average mechanical penetration rate is 5 m / hour. During the drilling process, the wellbore was good, and the downhole was always normal. After drilling, the electrical measurement showed that the wellbore was regular. Table 11 and Table 12 describe the drilling fluid properties of Example 2 and Example 3 applied in the field.

[0113] Table 11: Application of Example 2 in Jingping 16-14

[0114] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com