Prebending kinetics deviation control and fast drilling method

A pre-bending, dynamic technology, applied in directional drilling and other directions, can solve the problem of high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0157] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

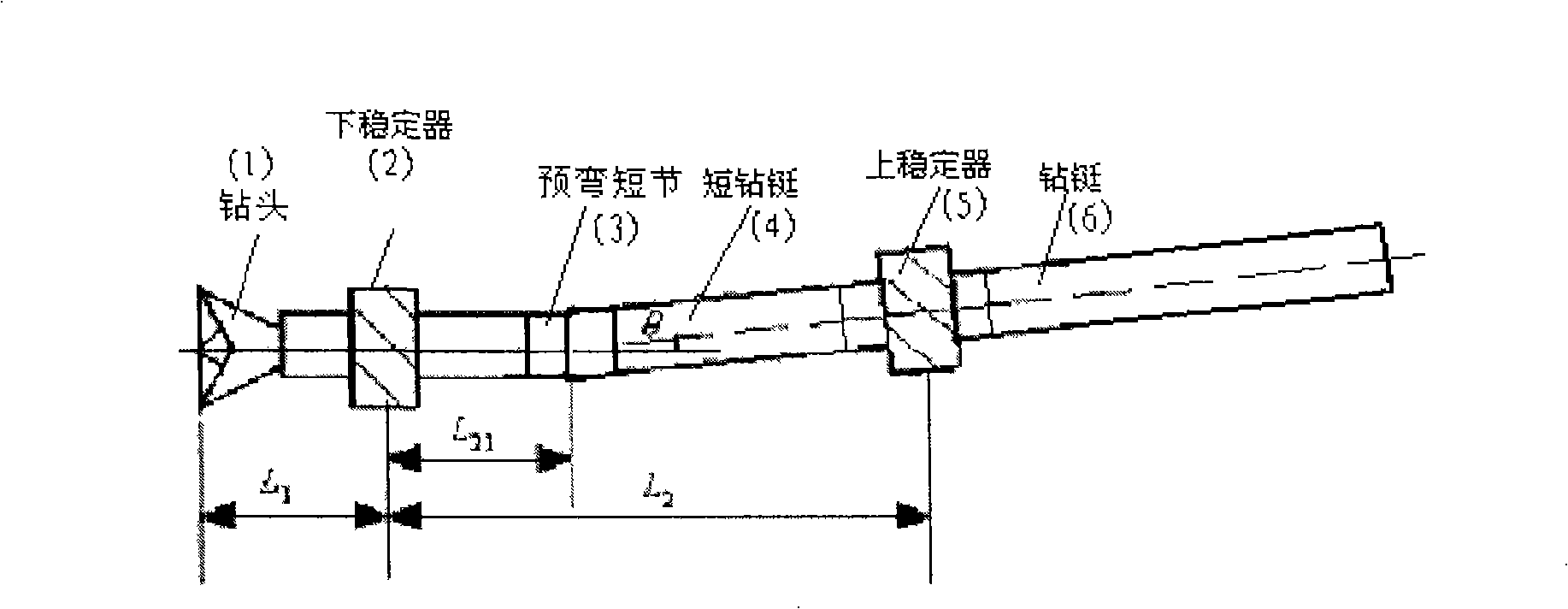

[0158] see figure 1 , this pre-bending dynamic anti-deflection drilling method adopts figure 1 The drill tool assembly with pre-bending structure shown is: a drill bit (1) is connected with a lower stabilizer (2), the lower stabilizer is connected with a pre-bent sub (3), and the pre-bend sub (3) passes through a The short drill collar (4) is connected to an upper stabilizer (5), which is connected to the upper drill string through the drill collar (6). The upper drill string is generally composed of drill collars, drill pipes and other downhole tool connections.

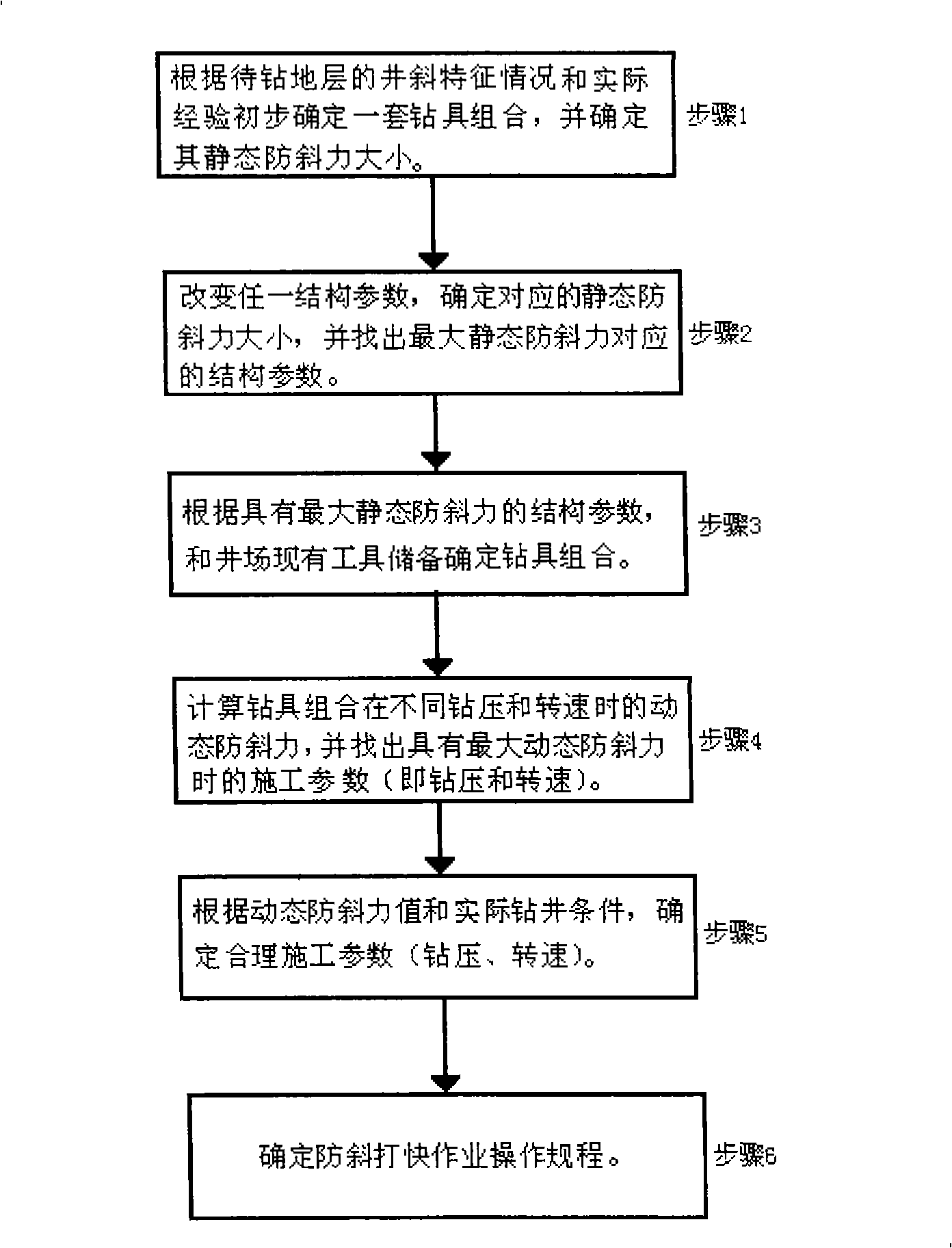

[0159] see figure 2 , the specific steps of the pre-bending dynamic anti-deflection drilling method are as follows:

[0160] 1. According to the characteristics of the well deviation of the formation to be drilled, a set of drilling tool assembly is preliminarily determined accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com