Cmc turbine engine blades and a rotor wheel for a turbine engine and a turbine engine integrating them

a technology of turbine engine blades and rotor wheels, which is applied in the direction of rotors, marine propulsion, vessel construction, etc., can solve the problem that the blades made of cmc cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

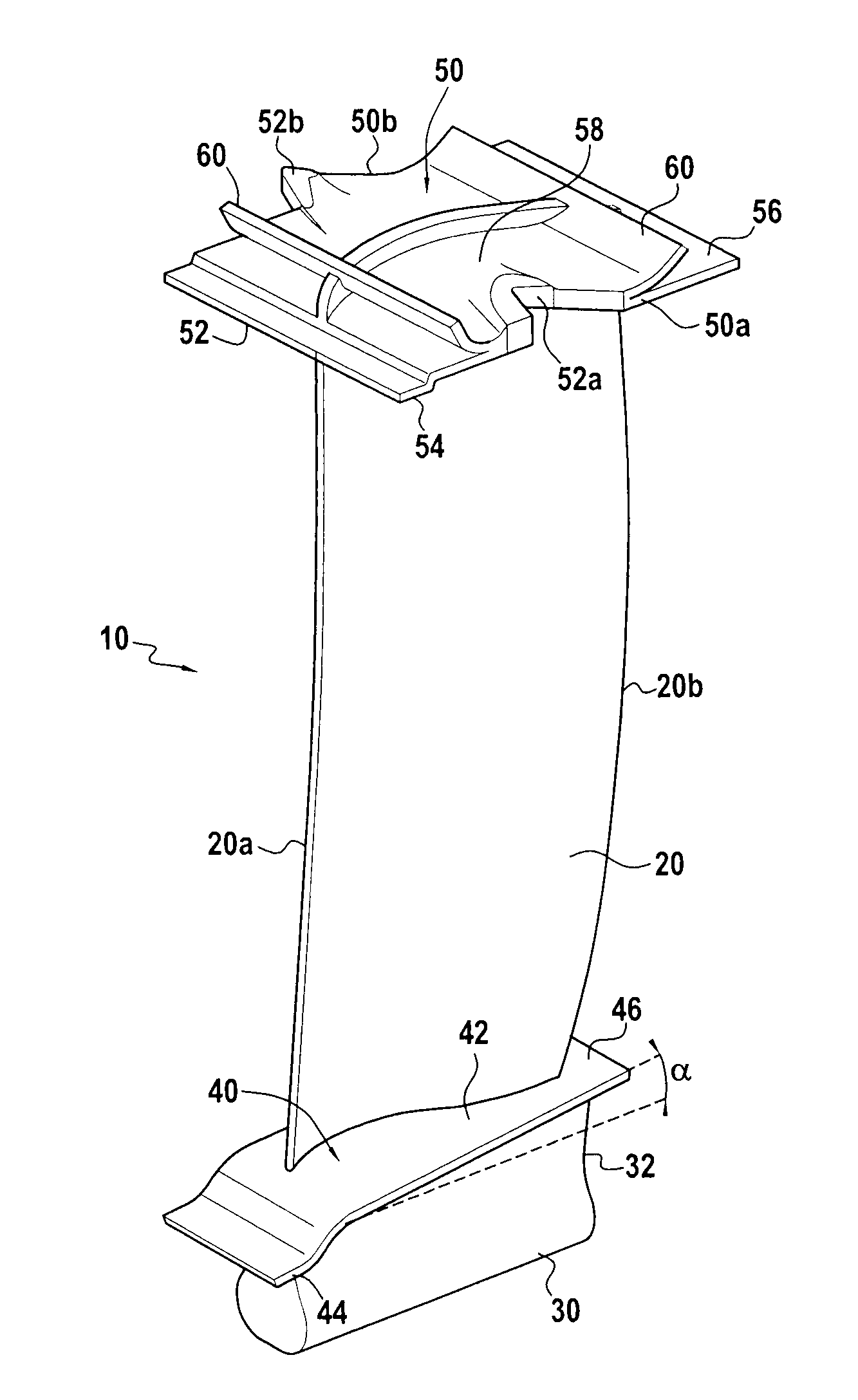

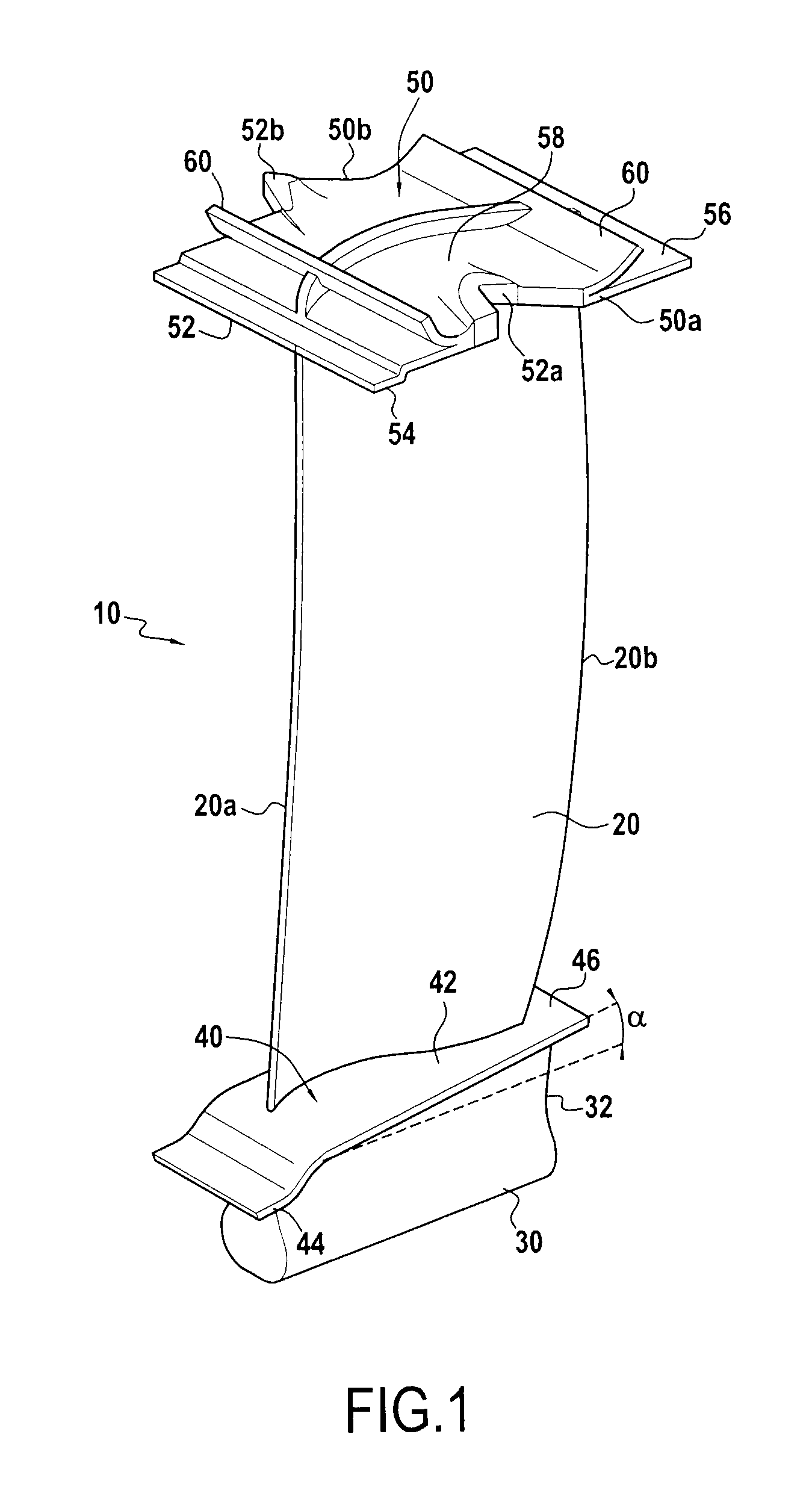

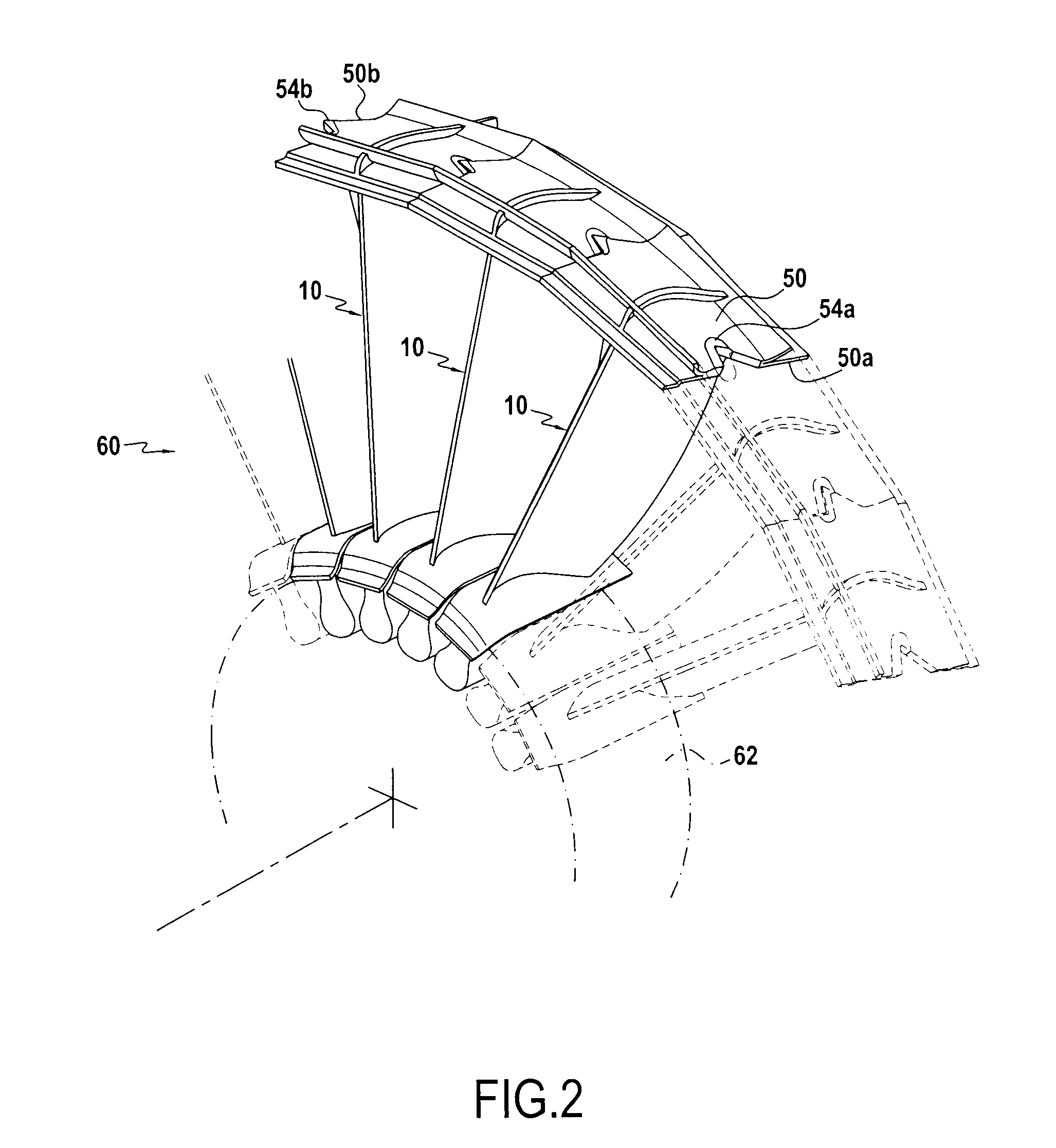

[0035]The invention is applicable to various types of turbine engine blade, in particular compressor blades or turbine blades for various spools of a gas turbine, e.g. a blade for a rotor wheel of an LP turbine, such as the blade 10 of FIG. 1.

[0036]In well-known manner, the blade 10 comprises an airfoil 20, a root 30 formed by a portion of greater thickness, e.g. presenting a bulb-shaped section, and extended by a tang 32, an inner platform 40 situated between the tang 30 and the airfoil 20 and an outer platform 50 in the vicinity of the free end of the airfoil 20.

[0037]The airfoil 20 extends in a longitudinal direction between the inner platform 40 and the outer platform 50, and in cross-section it presents a curved profile of varying thickness between its leading edge 20a and its trailing edge 20b. The root 30 is extended by the tang 32 so as to connect to the inner (or bottom) face of the inner platform 40.

[0038]At its radially inner end, the airfoil 20 is connected to the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com