High performance jack

a high-performance, jack technology, applied in the direction of printed capacitor incorporation, printed electric component incorporation, coupling device connection, etc., can solve the problem that the split pair will suffer a significant near-end cross-talk (next) problem, and achieve high throughput and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

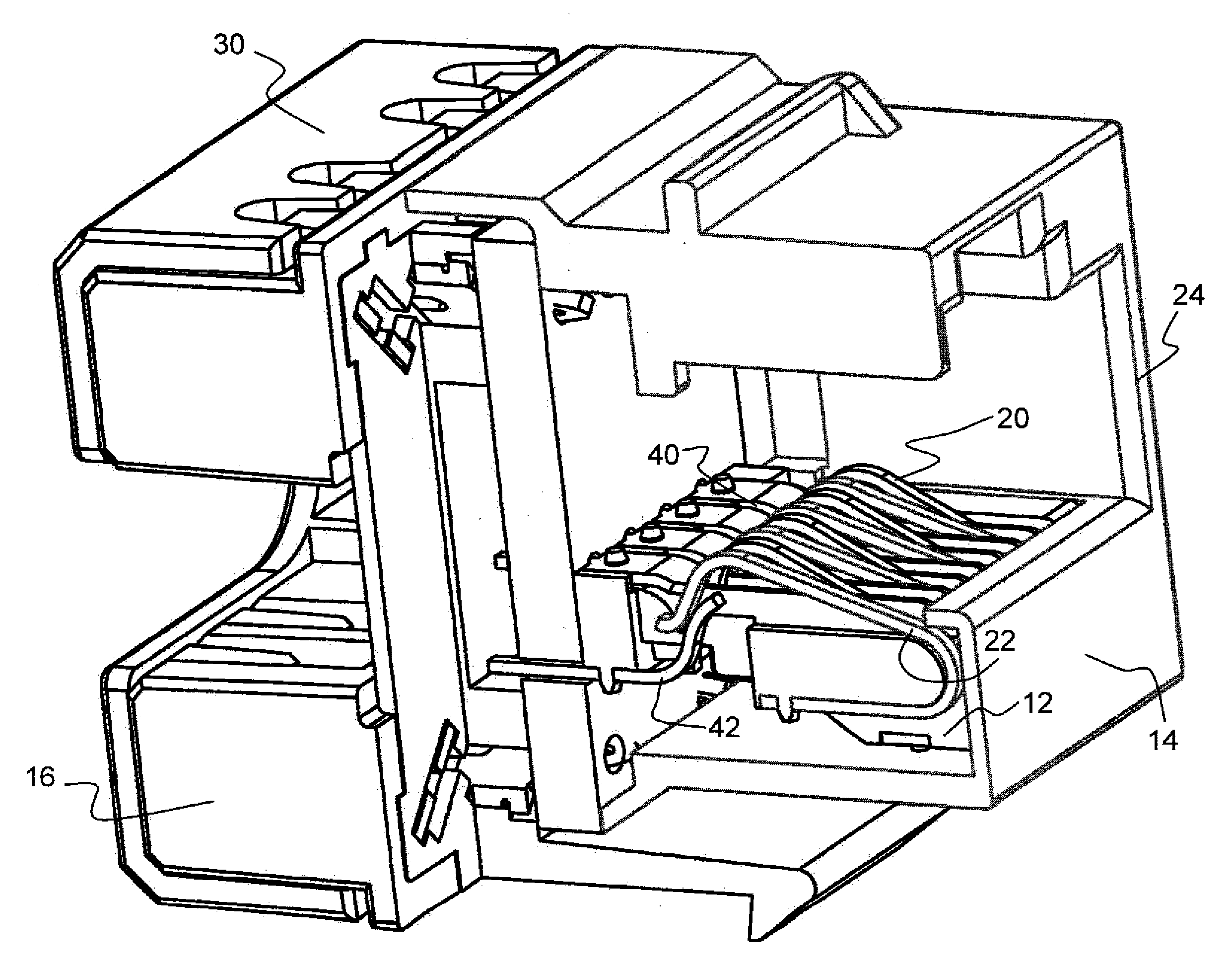

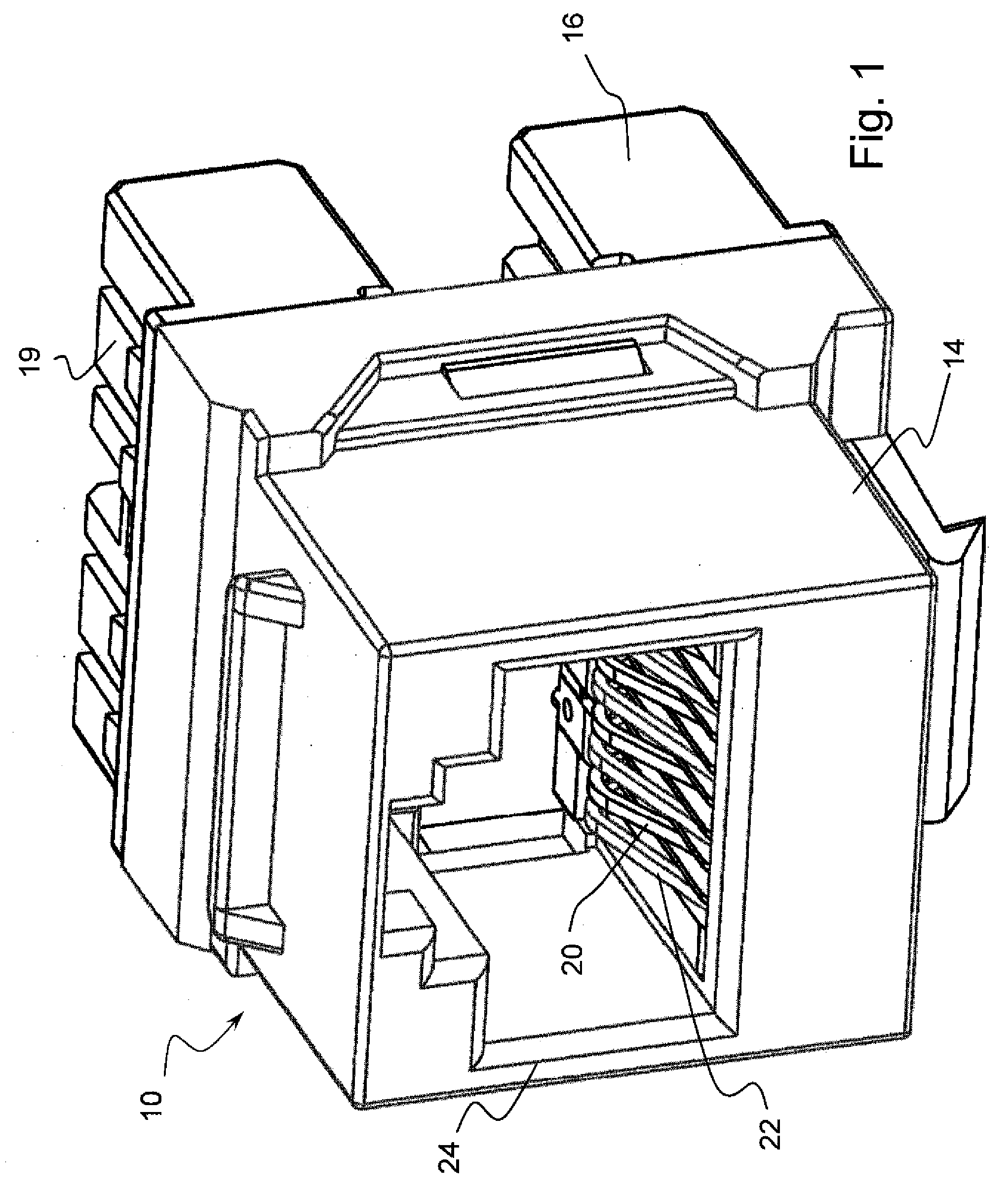

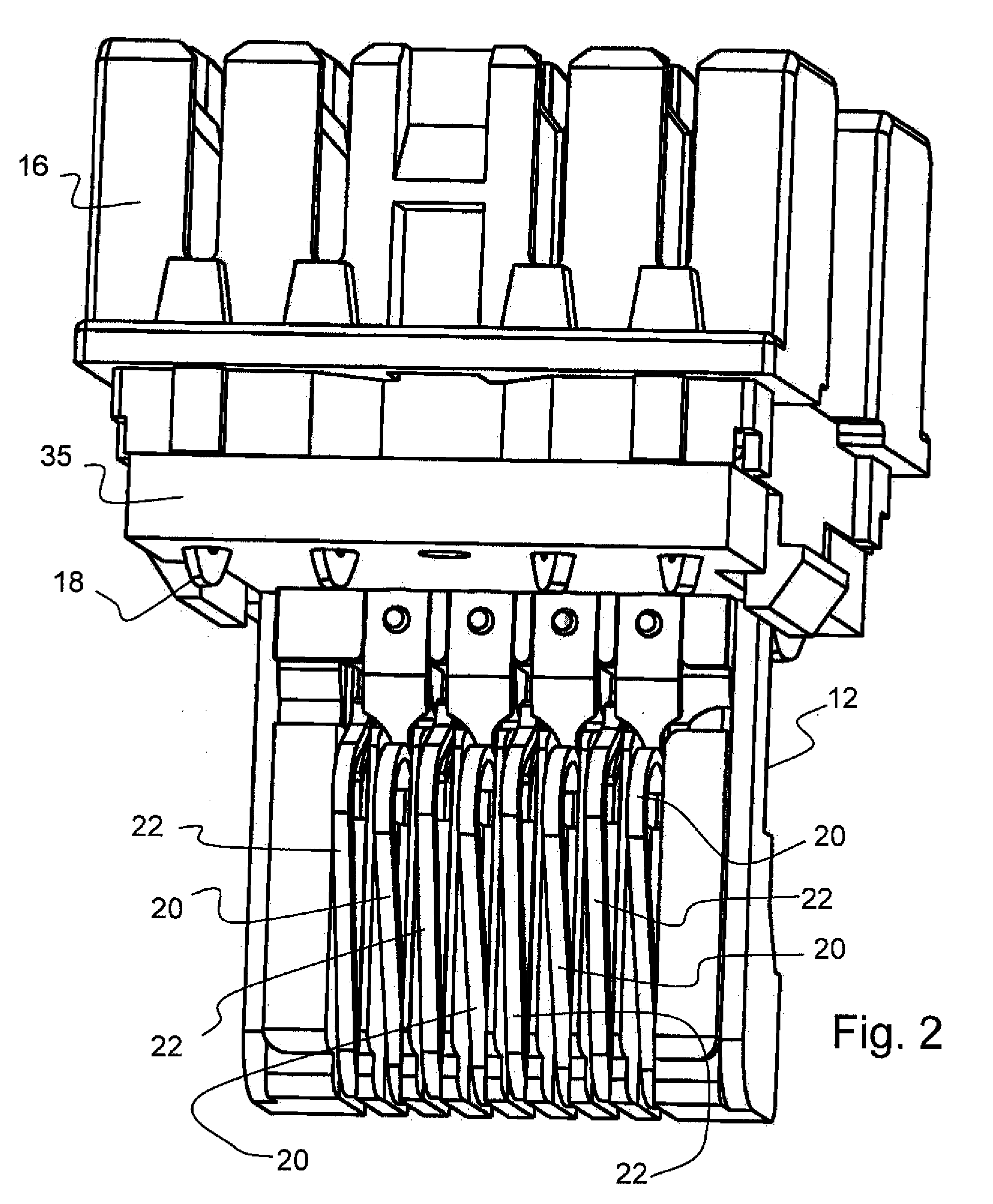

[0038] Referring to the drawings in particular, the invention comprises a high-performance jack. A first embodiment is shown in FIG. 1 with the high-performance jack generally designated 10. The high-performance jack includes a jack body formed with a base part 12 connected to an insulation displacement contact (IDC) part 16 and a cover part 14. FIG. 2 shows the structure with the cover part 14 removed. The cover part 14 defines a plug opening 24 into which a plug 32 may be inserted in a plug insertion direction (having a plug insertion direction axis). The IDC part 16 provides support for IDCs 18 terminated to a circuit board 35. The IDC part 16 has slots 19 for terminating wires in the IDCs 28. This region may be covered with a cover part 30 (FIG. 3).

[0039] The base part 12 supports the circuit board 35 and also supports a plurality of supported spring contact conductors designated 20 and 22. As can be seen in FIGS. 4 and 5, the supported spring contact conductors 20 and 22 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com