Graphene-reinforced titanium-based composite and preparation method thereof

A titanium-based composite material and graphene technology, applied in the field of materials, can solve the problems of poor anti-fretting wear performance, low wear resistance, easy adhesion, etc., and achieve the effect of high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

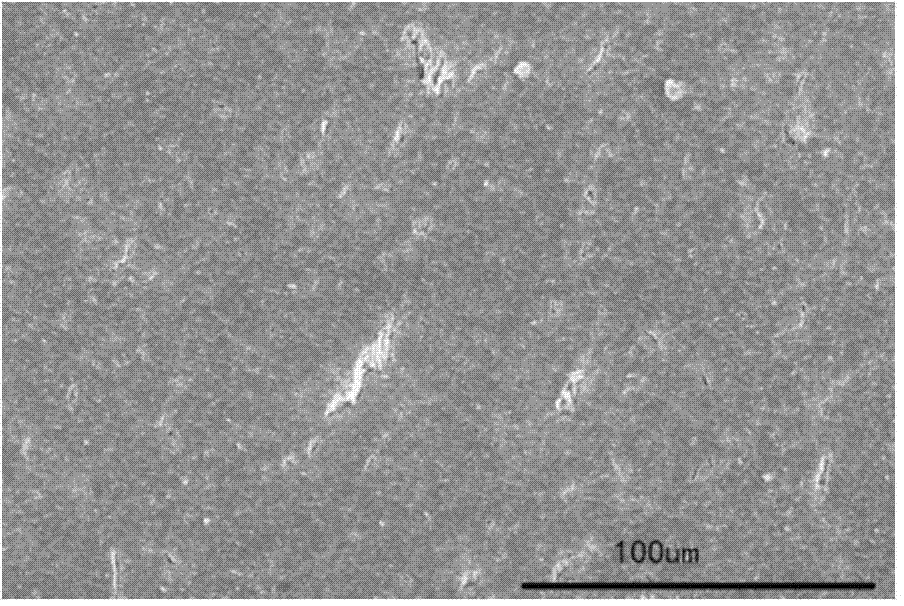

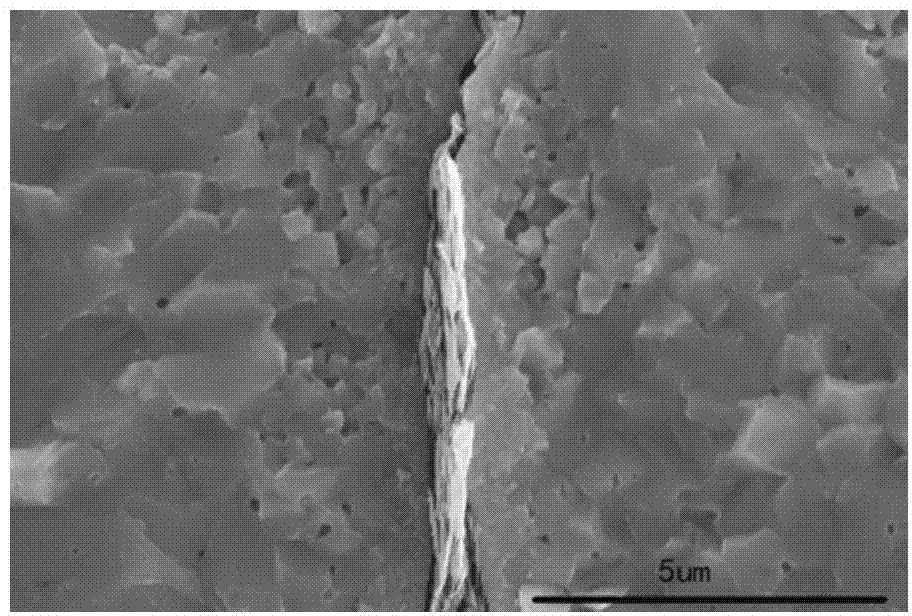

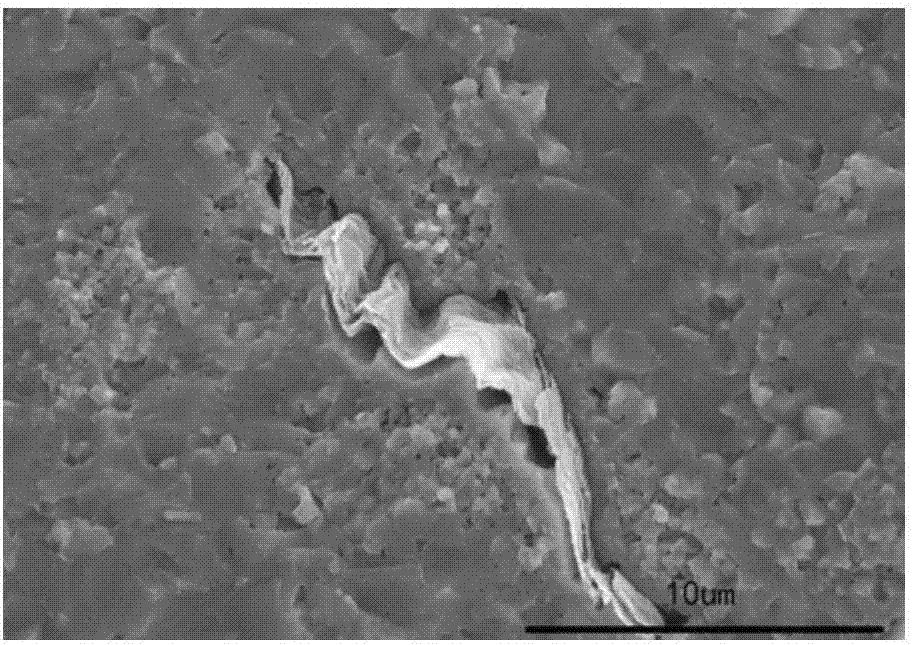

Image

Examples

preparation example Construction

[0030] The preparation method of the graphene-reinforced titanium-based composite material of the present invention uses graphene as a reinforcing phase, which not only increases the strength of traditional titanium and titanium alloys (alloys), improves their performance, and the obtained composite material has light weight, relatively The advantage of high strength.

[0031] Among them, graphene has sp 2 Two-dimensional carbon atom crystals with hybrid orbitals, low density (~1.06g / cm 3 ), large specific surface area (~2630m 2 g -1 ), with excellent mechanical properties (Young's modulus 0.5-1TPa, tensile strength up to 130GPa). Compared with carbon nanotubes, graphene has a larger specific surface area, so that the obtained composite materials have interfaces with high bonding strength.

[0032] The invention provides a graphene-reinforced titanium-based composite material, the preparation method of which is:

[0033] S1. Weigh titanium powder and graphene nanosheets, ...

Embodiment 1

[0048] The weight ratio of graphene to titanium powder is 0.5wt%, and the titanium powder and graphene nanosheets are weighed. The weighed graphene was ultrasonically dispersed for 30 minutes under the condition of sodium dodecylbenzenesulfonate as a dispersant, and then the weighed titanium powder was added to the graphene nanosheets for mixing, and the dispersion was continued for 30 minutes. The titanium powder and graphene nanosheets after mixing and dispersing are ball milled and dried. The ball milling conditions are: the ratio of ball to material is 4:1, and the speed of the ball mill is 350r / min. After drying, further grinding is performed. The mixed powder treated above is sintered in a spark plasma device. Among them, the heating rate is 200°C / min, the sintering pressure is 40MPa, the sintering temperature is 1100°C, and the holding time is 6min.

Embodiment 2

[0050] The weight ratio of graphene to titanium powder is 1.0wt%, and the titanium powder and graphene nanosheets are weighed. The weighed graphene was ultrasonically dispersed for 30 minutes under the condition of sodium dodecylbenzenesulfonate as a dispersant, and then the weighed titanium powder was added to the graphene nanosheets for mixing, and the dispersion was continued for 30 minutes. The titanium powder and graphene nanosheets after mixing and dispersing are ball milled and dried. The ball milling conditions are: the ratio of ball to material is 4:1, and the speed of the ball mill is 350r / min. After drying, further grinding is performed. The mixed powder treated above is sintered in a spark plasma device. Among them, the heating rate is 200°C / min, the sintering pressure is 40MPa, the sintering temperature is 1100°C, and the holding time is 6min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com