Magnesium alloy plastic process product and manufacture method thereof

A technology of plastic processing and manufacturing method, applied in metal processing equipment, manufacturing tools, metal rolling, etc., to achieve the effect of suppressing cracking or surface blackening, high strength, and ensuring extrudability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

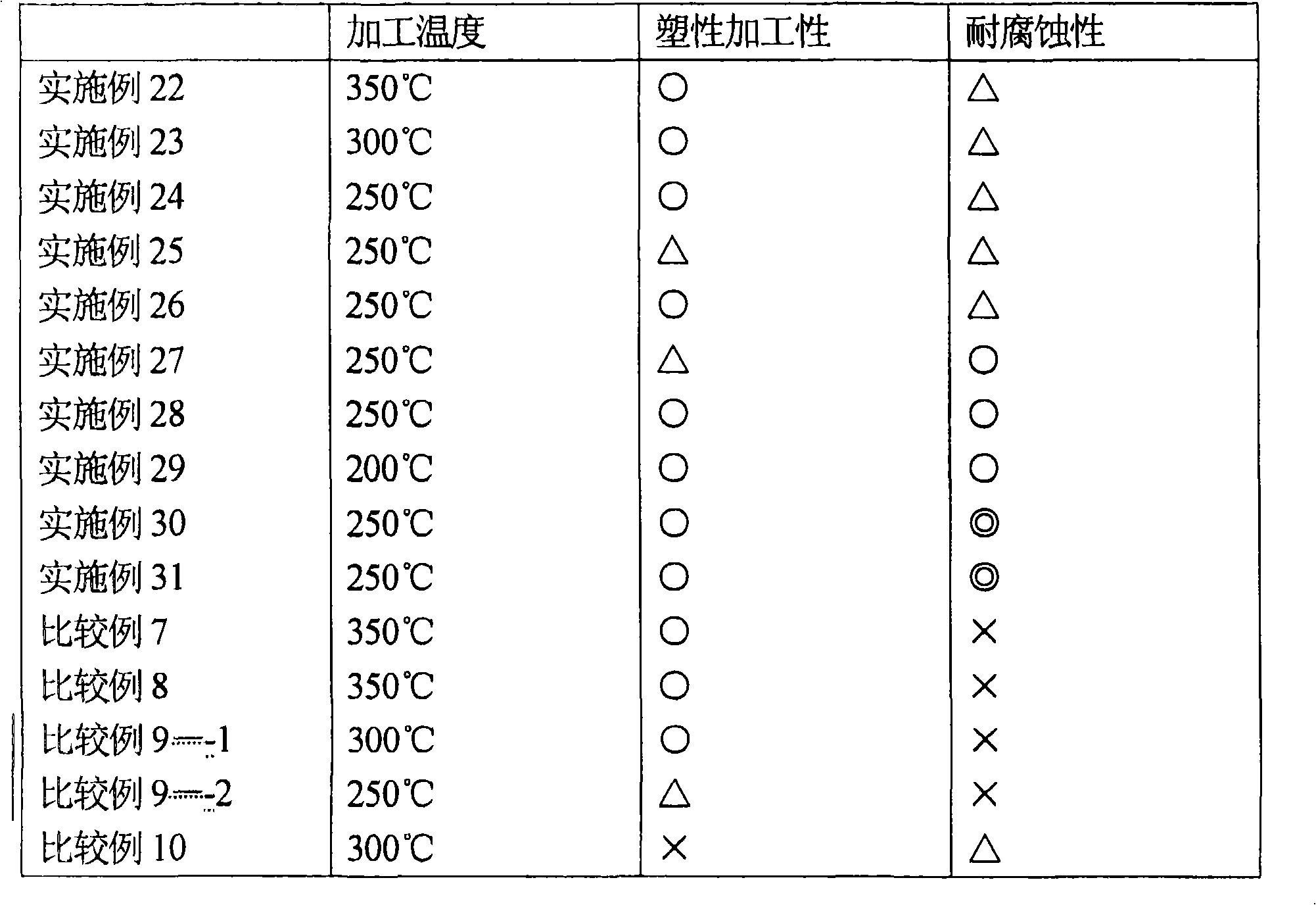

Examples

Embodiment 1 and comparative example 1~2

[0060] A Mg-5Al-2Ca-2MM (cerium alloy)-0.2Mn alloy was melted, and a cylindrical casting billet of φ168×500 mm was produced using a casting mold under the following conditions.

[0061] In Example 1, casting was performed continuously at a constant speed, and the molten metal was replenished at the shrinkage portion. In Comparative Example 1, small sparks occurred during melt retention. Furthermore, in Comparative Example 2, although the casting was performed continuously at a constant speed under the same conditions as in Example 1, melt shrinkage (concavity and convexity) remarkably occurred on the side surface.

[0062] Form 1

[0063] melting temperature

Embodiment 2 and comparative example 3-4

[0065] The cylindrical continuous casting billet produced in Example 1 was processed into a cylindrical extrusion billet of φ150×400 mm, and a φ30 rod was produced using an extruder 1650T under the following conditions.

[0066] In Example 2, in order to control the mold temperature, a cooling pipe was installed to circulate oil at 200°C to adjust the mold temperature, and the billet temperature at the mold exit was controlled below 470°C, and argon gas was blown to the billet. In Comparative Examples 3 and 4, the mold temperature was not controlled.

[0067] Form 2

[0068] billet temperature

[0069] In Example 2, the extrusion speed was 5 m / min, and the obtained extruded profile had a tensile strength of 270 MPa and an elongation of 10% (in the longitudinal direction).

Embodiment 3 and comparative example 5~6

[0071] The extruded profile produced in Example 2 was cut to form a φ30×50 billet for forging, and a φ42.5×25 cylinder was produced by closed die forging using a press forging machine 100T under the following conditions.

[0072] Form 3

[0073] soaking time

[0074] Example 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com