Ultrathin metallic resistance composite multi-frequency wave-absorbing material

A metal resistance and wave-absorbing material technology, applied in the field of wave-absorbing materials, can solve the problems of relatively thick thickness, narrow wave-absorbing bandwidth, single wave-absorbing frequency band, etc., and achieve the effect of easy processing, low thickness and high wave-absorbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the present invention, the preferred embodiments of the present invention will be described below in conjunction with specific embodiments, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention rather than limiting the claims of the present invention.

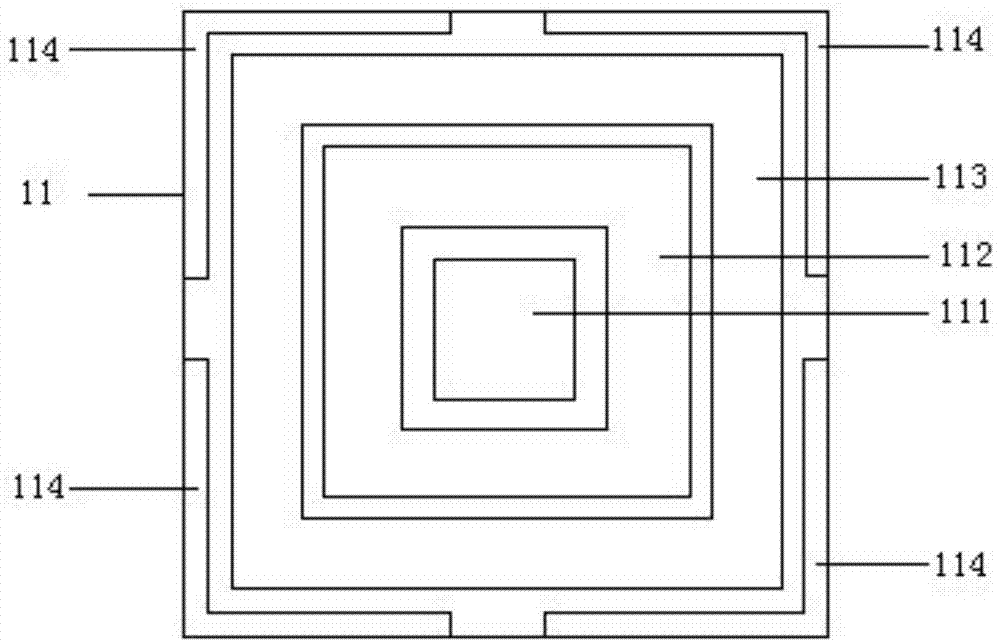

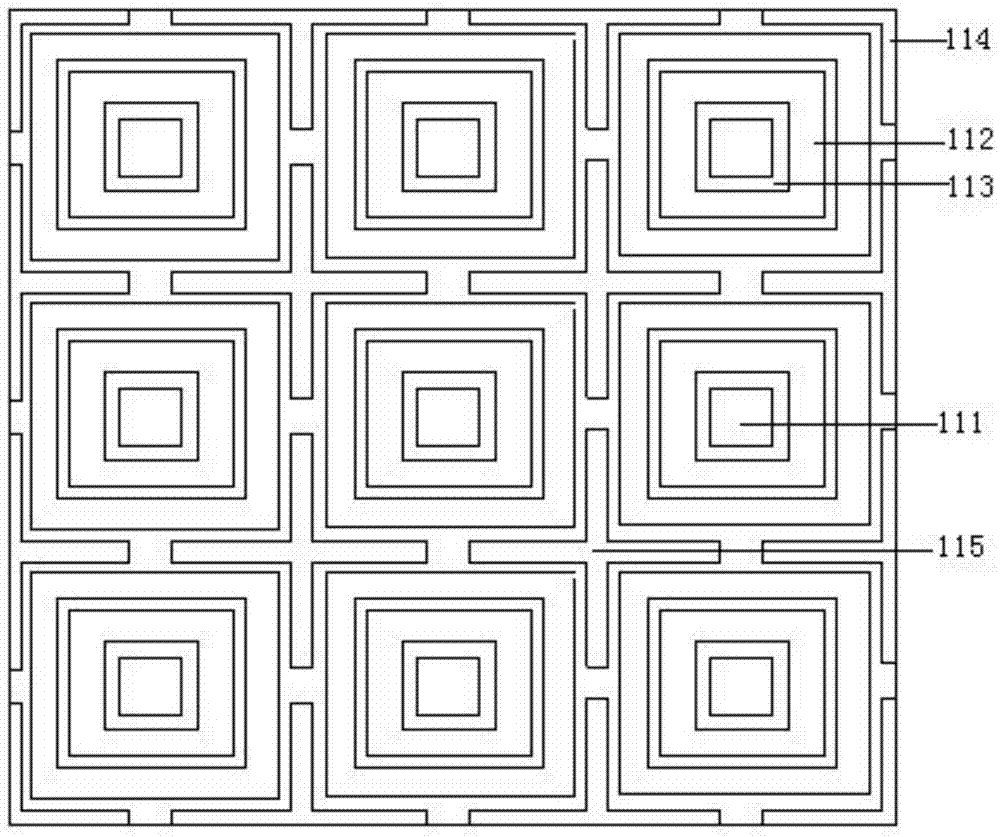

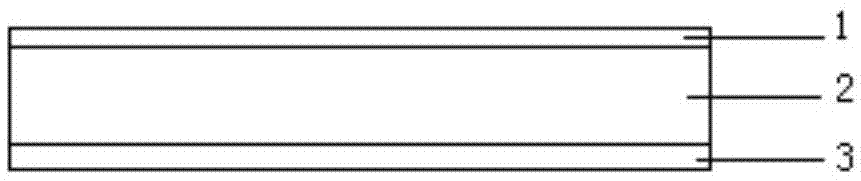

[0026] Such as figure 1 , the ultra-thin metal resistance composite multi-frequency absorbing material of the present invention includes a frequency selective surface 1 , a dielectric layer 2 and a metal bottom plate 3 . Wherein, the frequency selective surface 1 is composed of patch units 11 arranged periodically, and the patch unit 11 includes a square patch 111, a first square ring patch 112, a second square ring patch 113 and four identical L-shaped patches 114, the square patch 111, the first square ring patch 112 and the second square ring patch 113 are arranged in order according to the side length f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com