Insulated sheathing panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

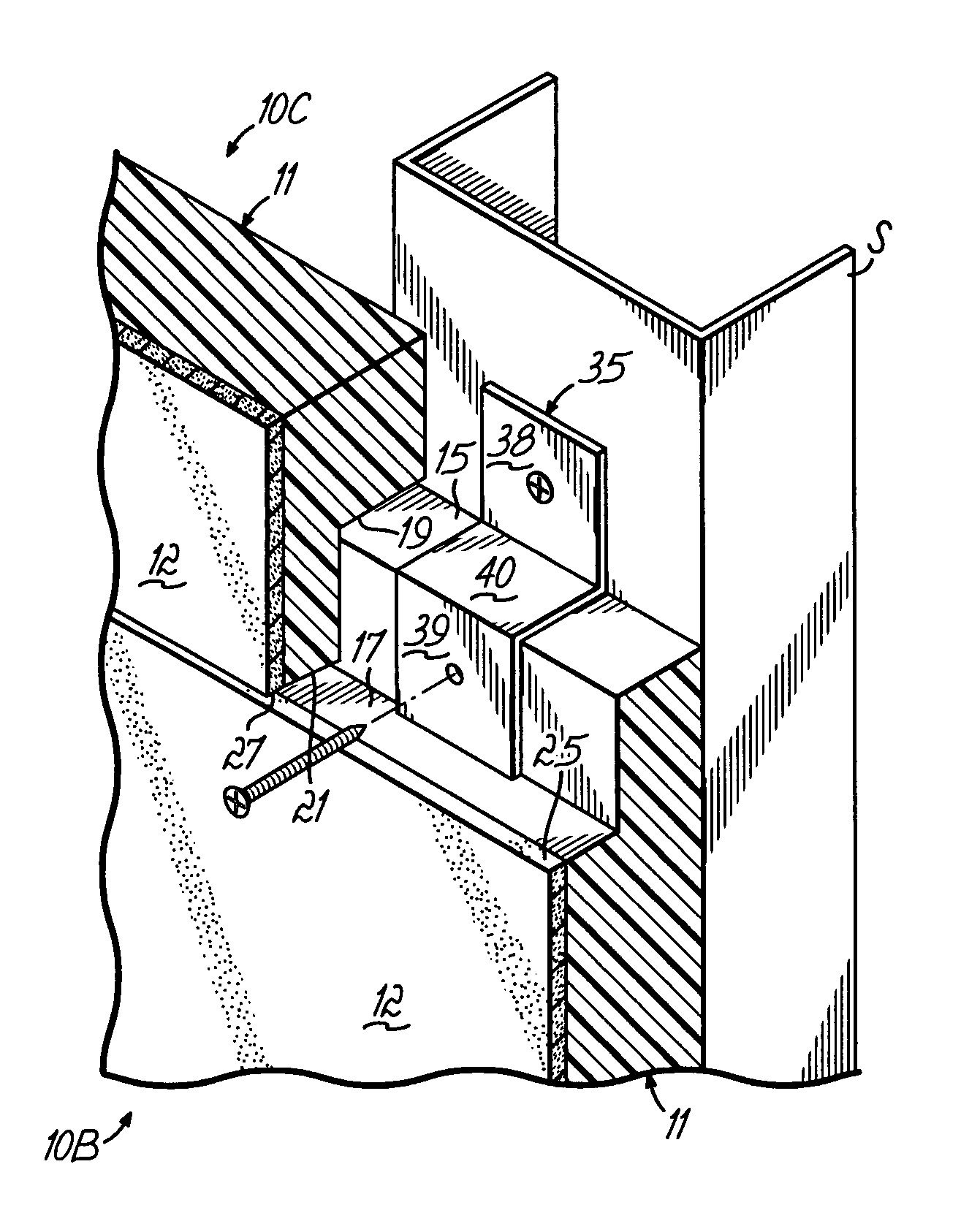

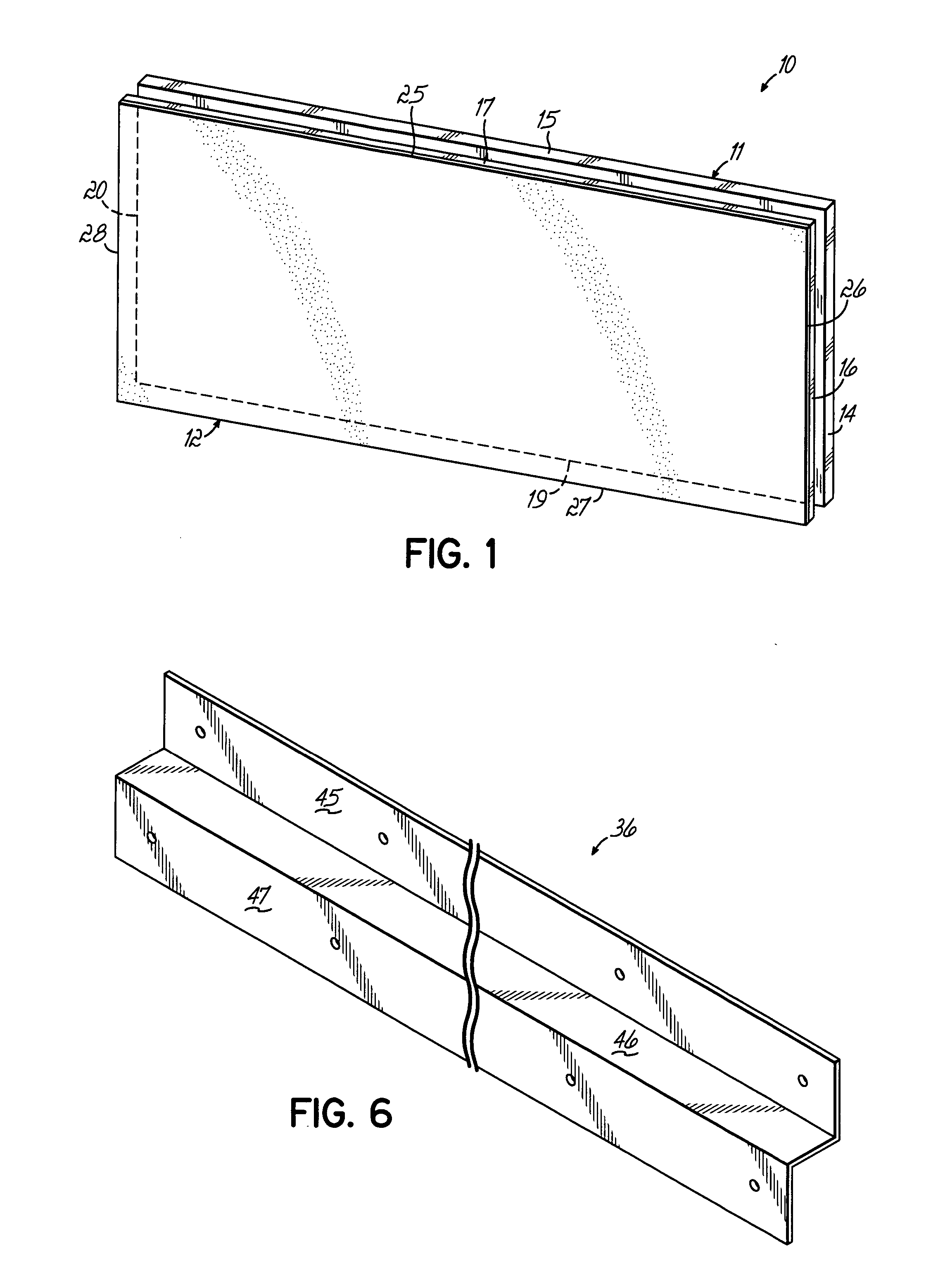

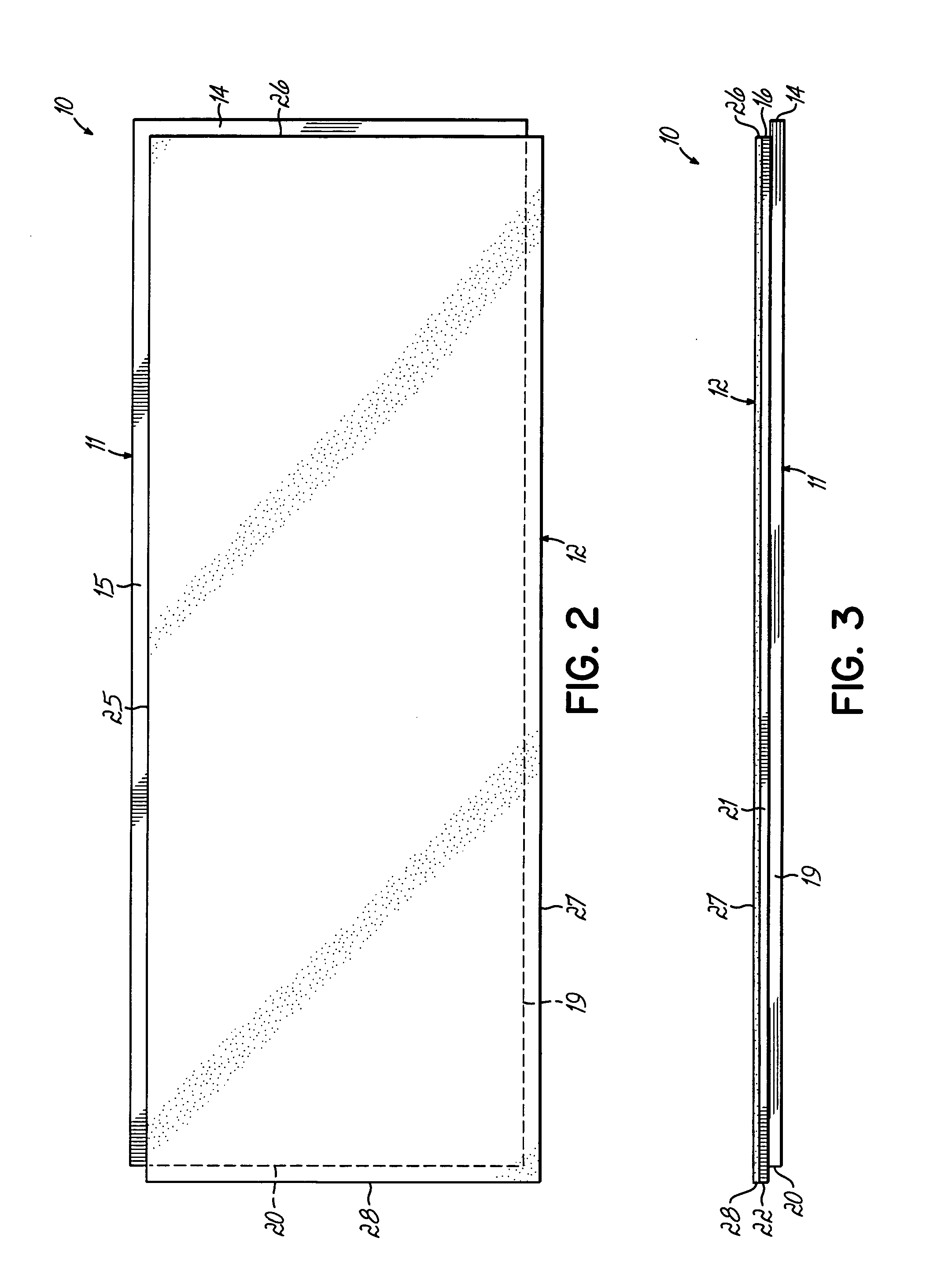

[0024] Turning now to the drawings, there is shown therein an insulated sheathing panel 10, according to one embodiment of the invention. Panel 10 has two primary components, an insulating member 11 and a facing 12.

[0025] Insulating member 11 is preferably comprised of a polystyrene foam, of either expanded or extruded manufacture, such as that polystyrene manufactured by Dow Chemical Company of Midland, Mich. Any suitable insulating material providing insulation, moisture resistance, workability and adhesive compatibility with facing 12, all as will be described, can be used. Insulating member 11 can be sawn, routed, cut or otherwise shaped as desired.

[0026] Facing 12 preferably comprises a cementitious panel with lightweight aggregate core and with mesh reinforced outer faces, all of known manufacture. One form of such facing is sold by Fin-Pan, Inc. of Hamilton, Ohio under its brand mark, “UTIL-A-CRETE”. Such facing and its manufacture is described in detail in one or more of U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com