Large-thickness blunt-trailing-edge wind-power airfoil profiles and a design method thereof

A technology with large thickness and blunt trailing edge, which is applied to wind turbines, wind turbines, and mechanical equipment in the same direction as the wind. It can solve the problems of single Reynolds number, unfavorable wind energy capture rate of large wind turbines, and severe lift coefficient stall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the object, technical solution and advantages of the present invention clearer, the invention will be further described in detail below with reference to the accompanying drawings and examples.

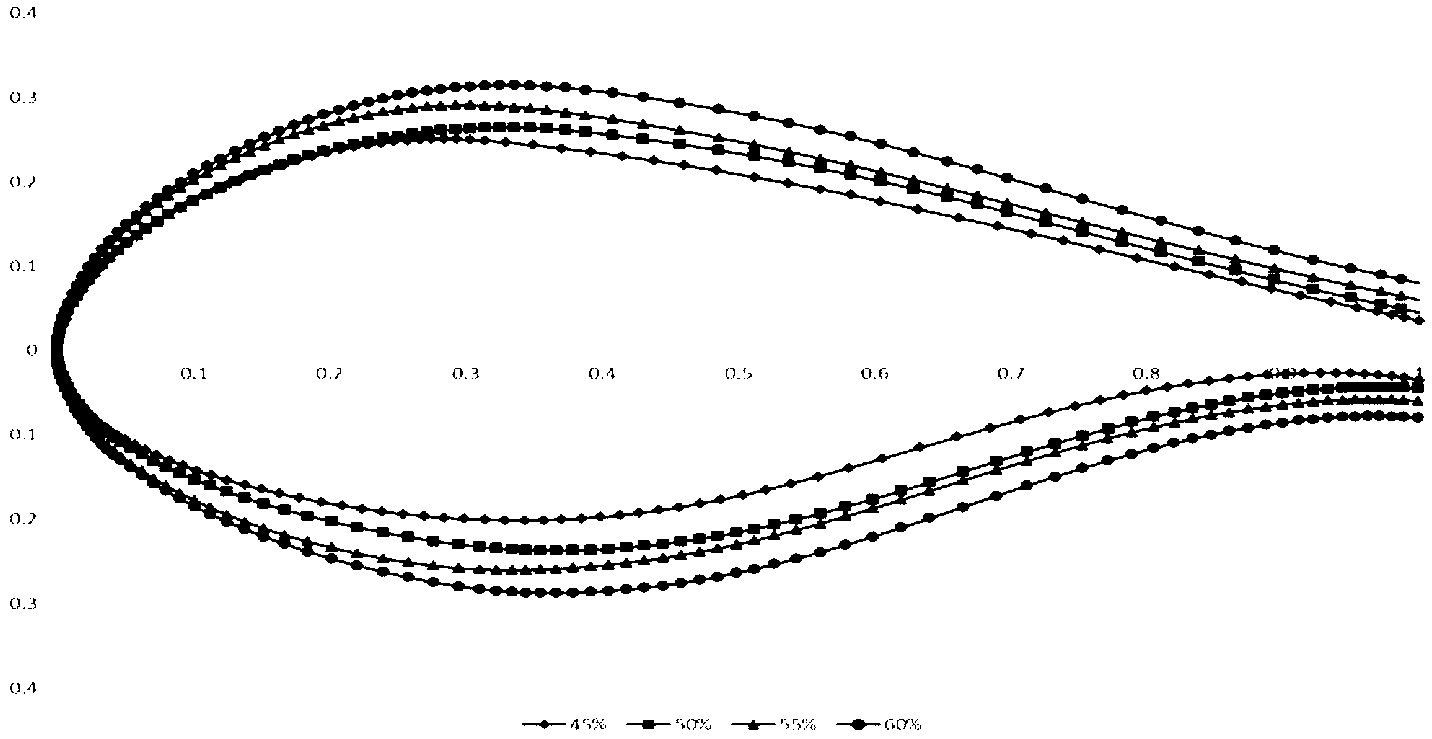

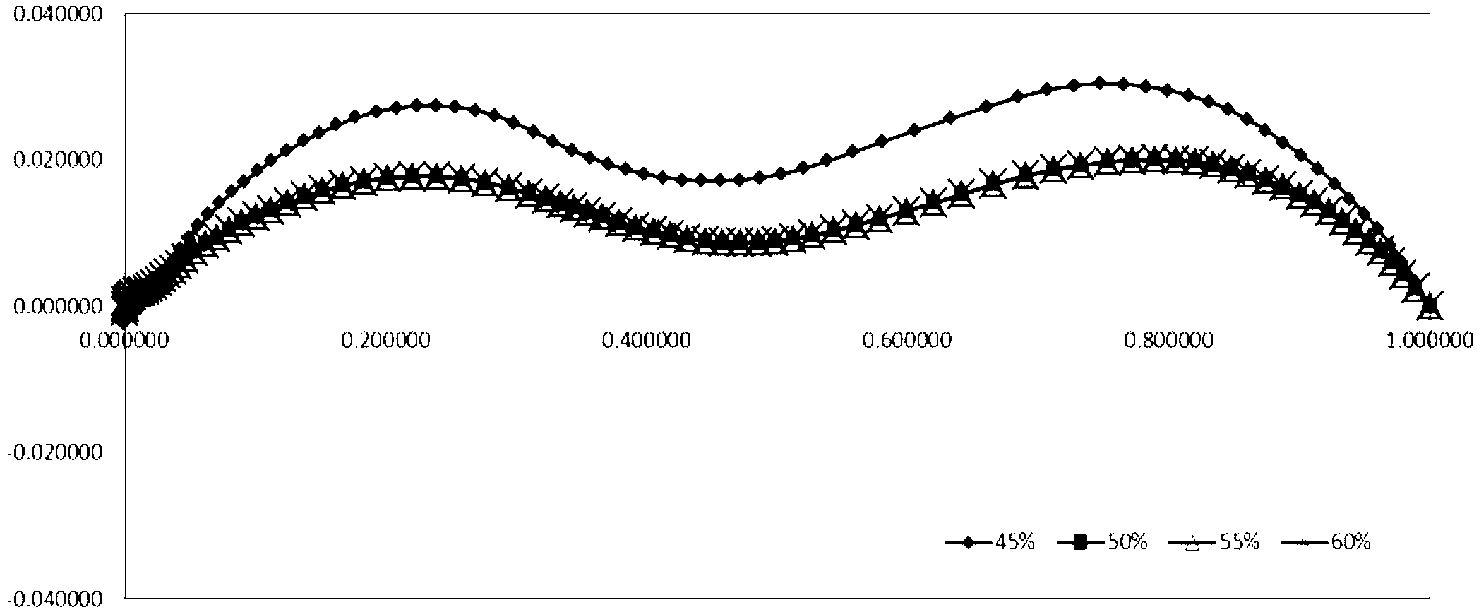

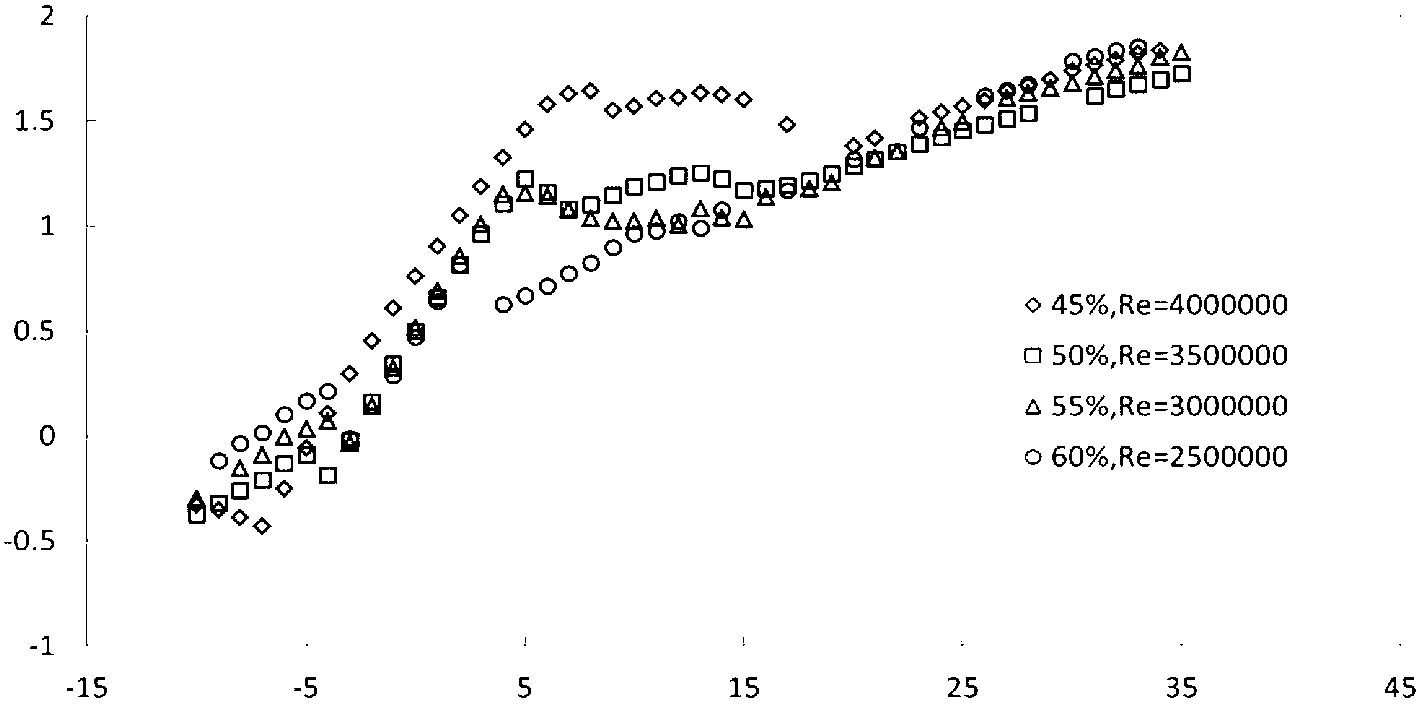

[0059] The airfoil proposed by the present invention is obtained by combining positive and negative methods. Starting from the original airfoil, using the positive design method, the camber distribution and the maximum thickness position of the airfoil are kept basically unchanged, and four airfoils with relative thickness are designed; further, the thick trailing edge shape design is realized. There are two main ideas for the design of the thick trailing edge: directly truncate the tail area of the original airfoil or keep the relative thickness constant and enlarge the trailing edge symmetrically. Directly truncating the trailing edge will significantly change the thickness and camber distribution of the airfoil, which has a great impact on the aerodynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com