Silicon graphene composite anode material of lithium ion battery and preparation method of silicon graphene composite anode material

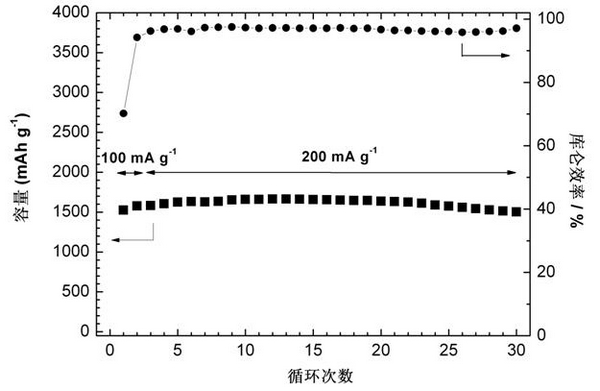

A graphene composite and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low production efficiency, high raw material cost, cumbersome preparation process, etc., achieve high yield and simple and easy preparation method , the effect of excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

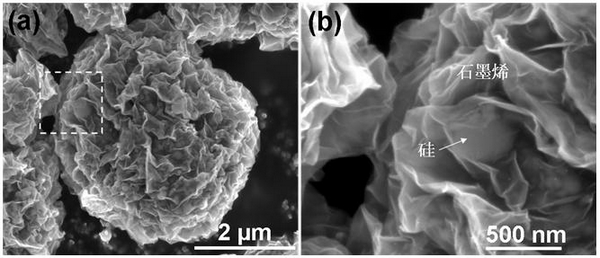

[0040] Disperse 0.1g of silicon powder (average particle size 100nm) and 0.0417g of graphene oxide in 100ml of deionized water, ultrasonically disperse it for 45min to make it evenly dispersed, and then spray dry it. The inlet temperature is 200°C and the outlet temperature is 110°C. Ionized water to obtain a composite material of graphene oxide and silicon; then place it in a high-temperature furnace, feed a mixed gas of hydrogen and argon, the volume content of hydrogen in the mixed gas of hydrogen and argon is 20%, and first raise the temperature Carry out high-temperature annealing treatment at 700°C, keep warm for 3 hours to reduce graphene oxide, and then cool naturally to room temperature to obtain a silicon-graphene composite negative electrode material for a lithium-ion battery. In the above preparation process, the added graphene oxide was finally reduced to generate graphene, and its loss rate was 40%.

[0041] Wherein the preparation of graphene oxide: 0.3 gram par...

Embodiment 2

[0045] Disperse 0.1g of silicon powder (average particle size 150nm) and 0.0017g of graphene oxide in 100ml of methanol, ultrasonically for 60min to disperse evenly, and then spray dry, the inlet temperature is 220°C, the outlet temperature is 140°C, methanol is removed, Obtain a composite material of graphene oxide and silicon; then place it in a high-temperature furnace, pass nitrogen gas, first raise the temperature to 1100 ° C for high-temperature annealing treatment, and keep it warm for 10 hours to reduce graphene oxide, and then naturally cool to room temperature, A silicon-graphene composite negative electrode material for a lithium ion battery is obtained, and the material forms spherical composite particles with a diameter of about 500 nm. In the above preparation process, the added graphene oxide was finally reduced to generate graphene, and its loss rate was 40%.

[0046] Wherein the preparation of graphene oxide: 0.3 gram of particle diameter is 30 micron flake gr...

Embodiment 3

[0049] Disperse 0.1g of silicon powder (average particle size 200nm) and 1.5g of graphene oxide in 200ml of ether, ultrasonically disperse it for 50min to make it evenly dispersed, then spray dry, the inlet temperature is 120°C, the outlet temperature is 80°C, remove the ether, Obtain a composite material of graphene oxide and silicon; then place it in a high-temperature furnace, pass a mixed gas of hydrogen and argon, the volume content of hydrogen in the mixed gas of hydrogen and argon is 1%, and first raise the temperature to 500°C Perform high-temperature annealing treatment, keep warm for 1 hour to reduce graphene oxide, and then cool naturally to room temperature to obtain a silicon-graphene composite negative electrode material for lithium-ion batteries, which forms spherical composite particles with a diameter of about 15 μm. In the above preparation process, the added graphene oxide was finally reduced to generate graphene, and its loss rate was 40%.

[0050] Wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com