Method for preparing high-heat-conducting silicon rubber compound material

A technology of thermally conductive silicone rubber and composite materials, used in heat exchange materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

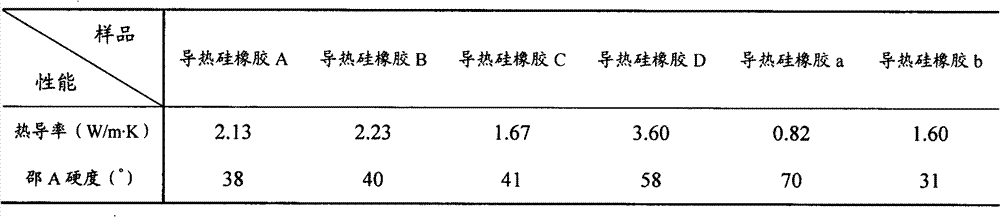

Examples

Embodiment 1

[0027] (1) configure the water dispersion that contains expanded graphite mass fraction as 2wt%, pour it into a ball mill jar, then put it into a planetary ball mill, process it for 24h under the condition of 300rpm, vacuum filter the gained solution, remove the solvent, and obtain Samples were vacuum dried for use.

[0028] (2) 80 parts by weight of silicone rubber raw rubber is dropped into a double-roll mill, and the processing temperature is at 25° C., and then 30 parts by weight are added, and the expanded graphite processed through step (1) has a viscosity of 500 cs (25 parts by weight). ℃) of methyl silicone oil, thin pass 5 to 10 times, then add 2 parts by weight of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (curing agent), and mix After uniformity, thin pass the next film.

[0029] (3) Put the kneaded silicone rubber into a suitable mold, and vulcanize for 10 minutes at 175° C. and 10 MPa. The second-stage vulcanization was treated in a blast oven at 200°C for 4 h...

Embodiment 2

[0031] (1) configuration contains the DMF dispersion liquid that expanded graphite mass fraction is 2wt%, pours in the ball mill tank, then puts into planetary ball mill, handles 24h under the condition of 300rpm, the gained solution is carried out vacuum suction filtration, removes solution, so The samples were vacuum dried for use.

[0032] (2) 80 parts by weight of silicone rubber raw rubber is dropped into a two-roll mill, and the processing temperature is at 25°C, and then 30 parts by weight are added, and the expanded graphite processed through step (1) has a viscosity of 20 parts by weight of 500cs (25 ℃) of methyl silicone oil, thin pass 5 to 10 times, then add 2 parts by weight of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (curing agent), and mix After uniformity, thin pass the next film.

[0033] (3) Put the kneaded silicone rubber into a suitable mold, and vulcanize at 175°C and 10MPa for 10min. The second-stage vulcanization was treated in a blast oven at 200°C...

Embodiment 3

[0035] (1) configure the ethanol dispersion containing expanded graphite mass fraction of 10wt%, then put it into an ultrasonic cell pulverizer, process it for 24h under the condition of 500W, carry out vacuum suction filtration to the gained solution, remove the solution, and the gained sample is vacuum-dried use.

[0036] (2) 80 mass parts of silicone rubber raw rubber is dropped into a double-roll mill, and the processing temperature is at 25° C., and then 30 mass parts are added, and the expanded graphite processed in step (1), 20 mass parts of formazan with a viscosity of 500cs Base silicone oil (25°C), thin pass 5-10 times, then add 2 mass parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (curing agent), knead After uniformity, thin pass the next film.

[0037] (3) Put the kneaded silicone rubber into a suitable mold, and vulcanize at 175°C and 10MPa for 10min. The second-stage vulcanization was treated in a blast oven at 200°C for 4 hours to obtain thermally condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com